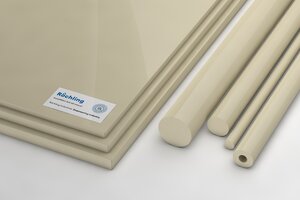

Mechanical & plant engineering: plastics for efficient processes

Even after heavy loads and countless operating hours, plant and machinery must continue to operate reliably. That means designers need a whole variety of materials depending on the application. These must, for instance, have good friction properties, high temperature resistance or thermal insulation. We offer plastics that are developed specifically for these requirements. We would be happy to advise you on the selection of suitable materials for your particular application.

Your advantages

- Good slide friction reduces the energy consumption of your machinery

- High process reliability

- Slip-stick effects are avoided

- Extended service intervals

- Consistent quality of your products

Areas of application

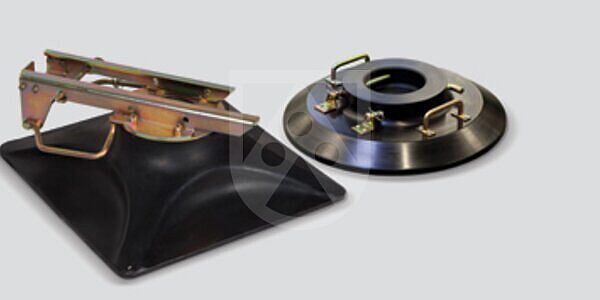

- Conveyor systems

- Automation

- Hydraulic wood and plastic presses

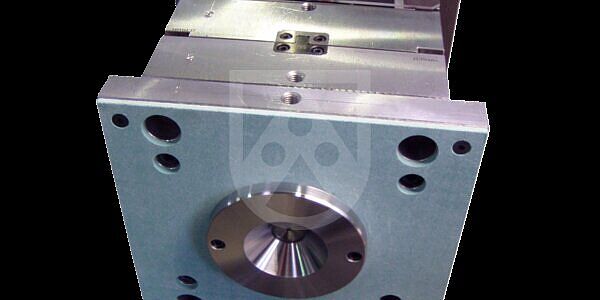

- Tool and mould construction

- Cutting machines

- GFK-UP

Durostone® UPM S2

- GFK-EP

Durostone® EPF S6

- GFK-EP

Durostone® EPX -M

- GFK-EP

Durostone® EPX -M S11

- GFK-EP

Durostone® EPX -M S7

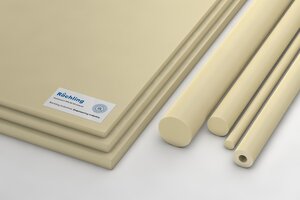

- PEEK

EtroX® V natural

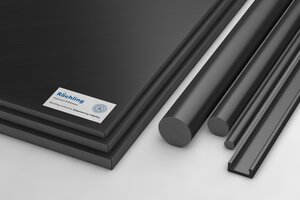

- PE > PE-UHMW - PE 1000

LubX® AST black

- PE > PE-UHMW - PE 1000

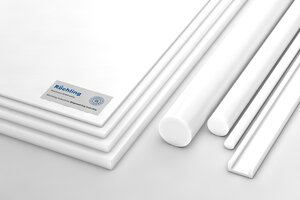

LubX® AST white

- PE > PE-UHMW - PE 1000

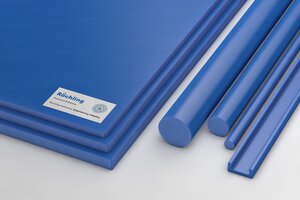

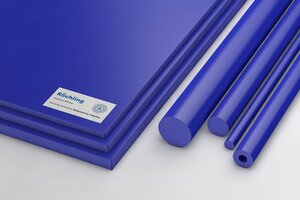

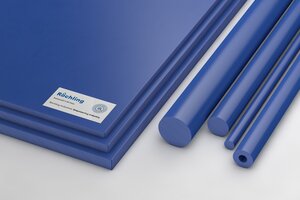

LubX® C blue

- PE > PE-UHMW - PE 1000

LubX® C natural

- PE > PE-UHMW - PE 1000

LubX® C white

- PE > PE-UHMW - PE 1000

LubX® CV blue

- PE > PE-UHMW - PE 1000

LubX® CV natural

- PE > PE-UHMW - PE 1000

LubX® S grey

- PE > PE-HD - PE 500

Polystone® D AST black

- PE > PE-HD - PE 500

Polystone® D BIO (mb) natural

- PE > PE-HD - PE 500

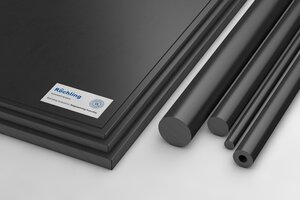

Polystone® D black

- PE > PE-HD - PE 500

Polystone® D blue

- PE > PE-HD - PE 500

Polystone® D brown

- PE > PE-HD - PE 500

Polystone® D EL black

- PE > PE-HD - PE 500

Polystone® D FDA black

- PE > PE-HD - PE 500

Polystone® D FG blue

- PE > PE-HD - PE 500

Polystone® D grey

- PE > PE-HD - PE 500

Polystone® D marbled white

- PE > PE-HD - PE 500

Polystone® D natural

- PE > PE-HD - PE 500

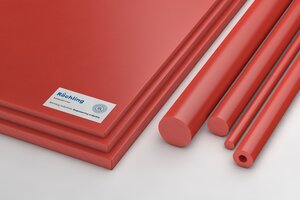

Polystone® D red

- PE > PE-HD - PE 500

Polystone® D white

- PE > PE-HD - PE 500

Polystone® D yellow

- PE > PE-HD - PE 500

Polystone® DR AST black

- PE > PE-HD - PE 500

Polystone® DR black

- PE > PE-HD - PE 500

Polystone® DR confetti

- PE > PE-HD - PE 500

Polystone® DR confetti black

- PE > PE-HD (PE 100)

Polystone® G CubX® black

- PE > PE-HD (PE 100)

Polystone® G CubX® UV-stabilized white

- PE > PE-HD - PE 300

Polystone® G EL black

- PE > PE-HD - PE 300

Polystone® G HD + FR (UL 94-V2) black

- PE > PE-HD - PE 300

Polystone® G HD + UV-stabilized blue

- PE > PE-HD - PE 300

Polystone® G HD + UV-stabilized green

- PE > PE-HD - PE 300

Polystone® G HD + UV-stabilized grey

- PE > PE-HD - PE 300

Polystone® G HD + UV-stabilized red

- PE > PE-HD - PE 300

Polystone® G HD black

- PE > PE-HD - PE 300

Polystone® G HD blue

- PE > PE-HD - PE 300

Polystone® G HD green

- PE > PE-HD - PE 300

Polystone® G HD grey

- PE > PE-HD - PE 300

Polystone® G HD natural

- PE > PE-HD - PE 300

Polystone® G HD red

- PE > PE-HD - PE 300

Polystone® G HD SK black

- PE > PE-HD - PE 300

Polystone® G HD white

- PE > PE-HD - PE 300

Polystone® G HD yellow

- PE > PE-HD - PE 300

Polystone® G natural

- PE > PE-HD - PE 300

Polystone® GR black

- PE > PE-UHMW - PE 1000

Polystone® M AST + FDA black

- PE > PE-UHMW - PE 1000

Polystone® M AST black

- PE > PE-UHMW - PE 1000

Polystone® M aubergine

- PE > PE-UHMW - PE 1000

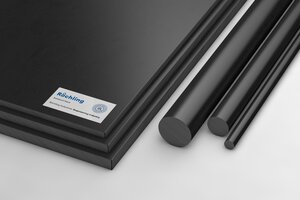

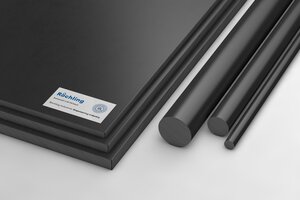

Polystone® M black

- PE > PE-UHMW - PE 1000

Polystone® M blue

- PE > PE-UHMW - PE 1000

Polystone® M brown

- PE > PE-UHMW - PE 1000

Polystone® M EHS + AST black

- PE > PE-UHMW - PE 1000

Polystone® M EHS black

- PE > PE-UHMW - PE 1000

Polystone® M EHS blue

- PE > PE-UHMW - PE 1000

Polystone® M EHS natural

- PE > PE-UHMW - PE 1000

Polystone® M EHS red

- PE > PE-UHMW - PE 1000

Polystone® M EHS white

- PE > PE-UHMW - PE 1000

Polystone® M EL + EHS black

- PE > PE-UHMW - PE 1000

Polystone® M EL black

- PE > PE-UHMW - PE 1000

Polystone® M ESD 90 black

- PE > PE-UHMW - PE 1000

Polystone® M Flametech AST black

- PE > PE-UHMW - PE 1000

Polystone® M green

- PE > PE-UHMW - PE 1000

Polystone® M grey

- PE > PE-UHMW - PE 1000

Polystone® M Microbloc blue

- PE > PE-UHMW - PE 1000

Polystone® M Microbloc natural

- PE > PE-UHMW - PE 1000

Polystone® M natural

- PE > PE-UHMW - PE 1000

Polystone® M orange

- PE > PE-UHMW - PE 1000

Polystone® M polyblue

- PE > PE-UHMW - PE 1000

Polystone® M red

- PE > PE-UHMW - PE 1000

Polystone® M Saphir blue

- PE > PE-UHMW - PE 1000

Polystone® M Slide + AST black

- PE > PE-UHMW - PE 1000

Polystone® M Slide + AST grey

- PE > PE-UHMW - PE 1000

Polystone® M Slide black

- PE > PE-UHMW - PE 1000

Polystone® M Slide blue

- PE > PE-UHMW - PE 1000

Polystone® M Slide grey

- PE > PE-UHMW - PE 1000

Polystone® M Slide natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft white

- PE > PE-UHMW - PE 1000

Polystone® M white

- PE > PE-UHMW - PE 1000

Polystone® M yellow

- PE > PE-UHMW - PE 1000

Polystone® M yellow pressed

- PE > PE-UHMW - PE 1000

Polystone® MK FL + AST black

- PE > PE-UHMW - PE 1000

Polystone® MK Slide blue

- PE > PE-UHMW - PE 1000

Polystone® MPG black

- PE > PE-UHMW - PE 1000

Polystone® MPG blue

- PE > PE-UHMW - PE 1000

Polystone® MPG green

- PE > PE-UHMW - PE 1000

Polystone® MPG red

- PE > PE-UHMW - PE 1000

Polystone® MR AST black

- PE > PE-UHMW - PE 1000

Polystone® MR black

- PE > PE-UHMW - PE 1000

Polystone® MR green

- PE > PE-HD - PE 500

Polystone® RGM black

- ABS

SustaABS grey

- PA > PA 6 G

Sustaglide® black

- PA > PA 6 G

Sustaglide® green

- PA > PA 6 G

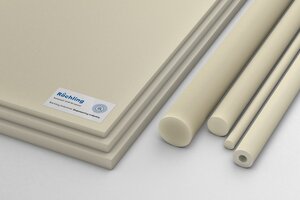

Sustaglide® natural

- PA > PA 12

Sustamid® 12 GF 30 natural

- PA > PA 12

Sustamid® 12 natural

- PA > PA 46

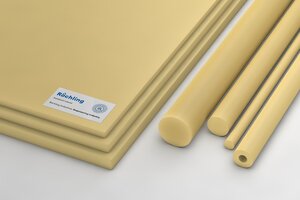

Sustamid® 46 brown

- PA > PA 6

Sustamid® 6 BIO (mb) natural

- PA > PA 6

Sustamid® 6 blue

- PA > PA 6

Sustamid® 6 FG natural

- PA > PA 6

Sustamid® 6 GC black

- PA > PA 6

Sustamid® 6 GC blue

- PA > PA 6

Sustamid® 6 GC natural

- PA > PA 6

Sustamid® 6 GF 30 black

- PA > PA 6

Sustamid® 6 MO black

- PA > PA 6

Sustamid® 6 natural

- PA > PA 6

Sustamid® 6 orange

- PA > PA 6

Sustamid® 6 red

- PA > PA 66

Sustamid® 66 black

- PA > PA 66

Sustamid® 66 GF 30 black

- PA > PA 66

Sustamid® 66 MO black

- PA > PA 66

Sustamid® 66 MO grey

- PA > PA 66

Sustamid® 66 natural

- PA > PA 66

Sustamid® 66 red

- PA > PA 6 G

Sustamid® 6G black

- PA > PA 6 G

Sustamid® 6G blue

- PA > PA 6 G

Sustamid® 6G green

- PA > PA 6 G

Sustamid® 6G grey

- PA > PA 6 G

Sustamid® 6G HS black

- PA > PA 6 G

Sustamid® 6G HS blue

- PA > PA 6 G

Sustamid® 6G LU red

- PA > PA 6 G

Sustamid® 6G M grey

- PA > PA 6 G

Sustamid® 6G MO black

- PA > PA 6 G

Sustamid® 6G natural

- PA > PA 6 G

Sustamid® 6G OL black

- PA > PA 6 G

Sustamid® 6G OL blue

- PA > PA 6 G

Sustamid® 6G OL green

- PA > PA 6 G

Sustamid® 6G OL grey

- PA > PA 6 G

Sustamid® 6G OL natural

- PA > PA 6 G

Sustamid® 6G OL red

- PA > PA 6 G

Sustamid® 6G OL yellow

- PA > PA 6 G

Sustamid® 6G PD 120 blue

- PEEK

SustaPEEK black

- PEEK

SustaPEEK FG natural

- PEEK

SustaPEEK MOD black

- PEEK

SustaPEEK natural

- PVDF

SustaPVDF black

- PVDF

SustaPVDF FG natural

- PVDF

SustaPVDF natural

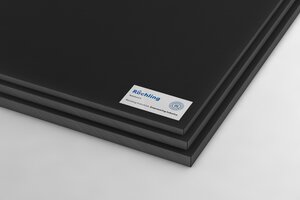

- POM-C

Sustarin® C BIO (mb)

- POM-C

Sustarin® C black

- POM-C

Sustarin® C blue

- POM-C

Sustarin® C brown

- POM-C

Sustarin® C DWS natural

- POM-C

Sustarin® C FG black

- POM-C

Sustarin® C FG natural

- POM-C

Sustarin® C GF 25 black

- POM-C

Sustarin® C GLD 350 blue

- POM-C

Sustarin® C green

- POM-C

Sustarin® C grey

- POM-C

Sustarin® C MDT blue

- POM-C

Sustarin® C natural

- POM-C

Sustarin® C orange

- POM-C

Sustarin® C red

- POM-C

Sustarin® C white

- POM-C

Sustarin® C yellow

- POM-H

Sustarin® H black

- POM-H

Sustarin® H natural

- PPSU

Sustason® PPSU black

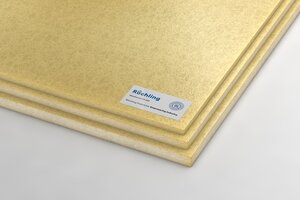

- Other

Glastherm® HT 200

- Other

Glastherm® HT 200 (SMC)

- Other

Glastherm® HT 220

- Other

Glastherm® HT 250 HQ

- Other

Glastherm® HT 250 M

- Other

Glastherm® HT 300

- Other

Glastherm® HT 500

- Other

Glastherm® HT LC

- PE > PE-HD - PE 300

Polystone® Cut-Rite black

- PE > PE-UHMW - PE 1000

Robalon® BIO

- PE > PE-UHMW - PE 1000

Robalon® E

- PE > PE-UHMW - PE 1000

Robalon® FG

- PE > PE-UHMW - PE 1000

Robalon® GL

- PE > PE-UHMW - PE 1000

Robalon® S

- PE > PE-UHMW - PE 1000

Robalon® W

- PE > PE-UHMW - PE 1000

Robalon® Z

- PVC-U

Trovidur® EC N black

- PVC-U

Trovidur® EC N green

- PVC-U

Trovidur® EC N grey

- PVC-U

Trovidur® EC N orange

- PVC-U

Trovidur® EC N red

- PVC-U

Trovidur® EC N white

- PVC-U

Trovidur® ES FB

- PVC-U

Trovidur® ES grey

- PVC-U

Trovidur® ET transparent

- PVC-U

Trovidur® PN grey

- PA > PA 12 G

Lamigamid® 1200

- PA > PA 12 G

Lamigamid® 1210

- PA > PA 12 G

Lamigamid® 1220

- PA > PA 6 G

Lamigamid® 300

- PA > PA 6 G

Lamigamid® 304

- PA > PA 6 G

Lamigamid® 307

- PA > PA 6 G

Lamigamid® 309

- PA > PA 6 G

Lamigamid® 314

- PA > PA 6 G

Lamigamid® 317

- PA > PA 6 G

Lamigamid® 319

- PA > PA 6 G

Lamigamid® 339

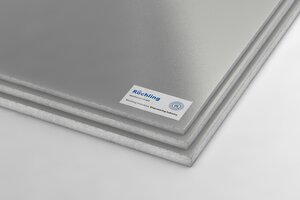

- PTFE

Fibracon® PTFE CLF

- PTFE

Fibracon® PTFE FGB

- PE > PE-UHMW - PE 1000

LubX® CV+ blue

- PE > PE-HD - PE 500

Polystone® D PIR black

- PE > PE-HD - PE 300

Polystone® G HD PIR black extruded

- PE > PE-UHMW - PE 1000

Polystone® M AST PIR black

- PE > PE-UHMW - PE 1000

Polystone® M BIO (mb) natural

- PE > PE-UHMW - PE 1000

Polystone® M PIR green

- PE > PE-UHMW - PE 1000

Polystone® M PIR natural

- POM-C

Sustarin® C ID blue

- POM-C

Sustarin® C PIR black

- Phenolic Resin

Laminex® 2010

- Phenolic Resin

Laminex® 2100

- Phenolic Resin

Laminex® 2101

- Phenolic Resin

Laminex® 2140

Arrange technical advice

The performance and reliability of materials used in mechanical and plant engineering are influenced by a whole variety of factors. These factors must be taken into account in order to select the right materials. Examples:

- Mechanical loading

- Thermal loading

- Slide partner

- Cycle times

- Contact with operating resources, parting agents, lubricants and detergents

- Construction requirements, dimensions and tolerances

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.

![[''] ['']](/fileadmin/_processed_/a/6/csm_Semi_Finished_Thermo_Plastics_3_cb0e2715de.jpg)

![[''] ['']](/fileadmin/_processed_/f/e/csm_Banner_CNC_Machined_Components_4_403f8d6faf.jpg)

![[Translate to English India:] [Translate to English India:]](/fileadmin/_processed_/f/5/csm_Durostone-Glastic-Composite-Sheets_e457a98737.jpg)