Heavy-duty plastic components for crane and hoisting technology

Heavy loads are the order of the day for developers in crane and hoisting equipment. Cranes and hoisting equipment have to be designed for ever increasing load capacities and combine high operational safety with a long service life. For several decades, we have been supporting manufacturers in this task based on our heavy-duty plastic components.

Components made from our materials contribute to the performance and reliability of many types of cranes and hoisting equipment all over the world. Owing to their excellent heavy-duty properties, abrasion resistance and zero maintenance, they often replace steel components. Our plastic components significantly extend the servicelife of the cables, prevent stick-slip effects and in that way increase the efficiency of cranes and hoists.

Application examples:

- Mobile cranes

- Railway cranes

- Truck loading cranes

- Tower cranes

- Dockside cranes

- Marine and offshore cranes

- Gantry and bridge cranes

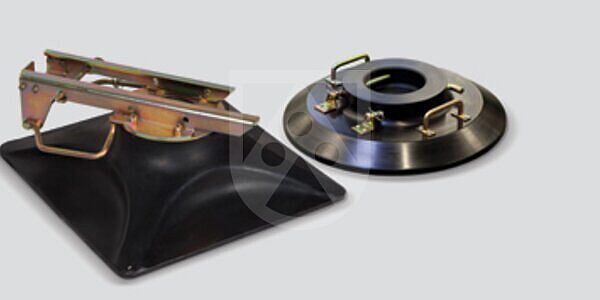

Typical components:

- Sheaves

- Pulleys

- Support plates

- Sliding elements

For efficient and powerful cranes

Cranes are constantly subjected to high loads and have to be absolutely reliable even in demanding areas of application. In cooperation with our customers, we aim to increase performance and reliability, reduce maintenance times and optimise safety.

- PA > PA 6 G

Sustaglide® green

- PA > PA 6 G

Sustaglide® natural

- PA > PA 12 G

Lamigamid® 1200

- PA > PA 6 G

Lamigamid® 300

- PA > PA 6 G

Lamigamid® 314

- PA > PA 6 G

Lamigamid® 318

- PA > PA 6 G

Lamigamid® 319

- PA > PA 6 G

Lamigamid® 339

- PA > PA 6 G

Lamigamid® 400B

Download

Arrange for technical consultation

The performance and service life of materials and components for cranes and hoisting equipment is determined by various influencing factors. These factors have to be taken into account for the proper selection and design. For instance:

- Mechanical stress

- Tribological requirements (friction and wear)

- Weight

- Contact with corrosive seawater

- Contact with equipment

- Extreme weather (UV) and abrasion (sand/waves)

We would be happy to assist you in selecting the proper material for your application. Just use our contact form at the bottom of the page and drop us a note.