[Translate to Japanese:] Materials and solutions for Wafer handling

[Translate to Japanese:]

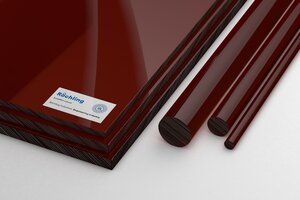

A typical semiconductor factory (fab) includes hundreds of machines that perform a variety of processes for wafer production. Processes include deposition, material removal, patterning, modification of electrical properties, and more. A common element across all these machines is the need for wafer handling tools. These tools include wafer picks/wands, cassettes, FOUPs, grip effectors and automated or robot wafer handlers.

[Translate to Japanese:] Arrange technical advice

[Translate to Japanese:]

The performance and service life of plastics for use in the semiconductor industry are influenced by a variety of factors. These criteria need to be considered in order to make the right choice in materials. Examples:

- Antistatic or conductive properties

- Operating temperature

- Contact with chemicals

- Design requirements

- Dimensions and tolerances

- Flame retardancy

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page.