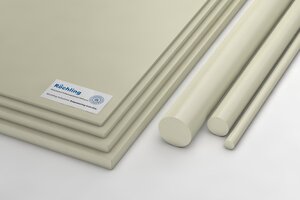

Plastics for high performance and low maintenancen steel-pickling plants

The efficiency of steel straining plants is influenced by different factors: Constructors must consider the chemical media and usage temperatures, in particular in staining technology. Our plastics are specifically developed for these requirements: They have a very high chemical resilience, heat resilience and are easy to process. This increases performance capacity and longevity of your facilities. We will gladly advise you in selecting the right materials for your application.

Your advantages

- High process safety

- High resilience against the media used in the process

- Suitable for high usage temperatures

- Easy processing and weldability

Typical areas of application

- Steel staining plants

- Stainless steel staining plants

Arrange technical advice

The performance and reliability of materials for steel pickling-plants are influenced by a variety of factors. These criteria need to be considered in order to make the right choice. Examples:

- Composition and concentration of the chemical media

- Use of tension-crack forming media

- Usage temperature

- Design of the tank

- Construction conditions

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.