Trovidur® EC-FR

PVC-U

Your partner for PVC-U sheets ‘Made in Germany’

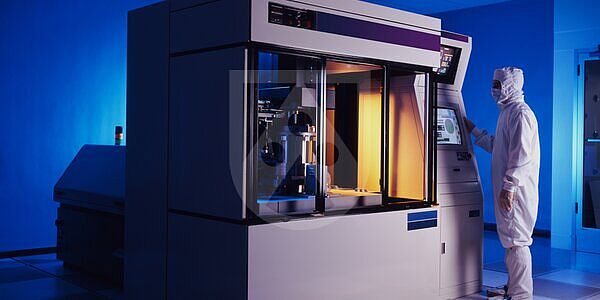

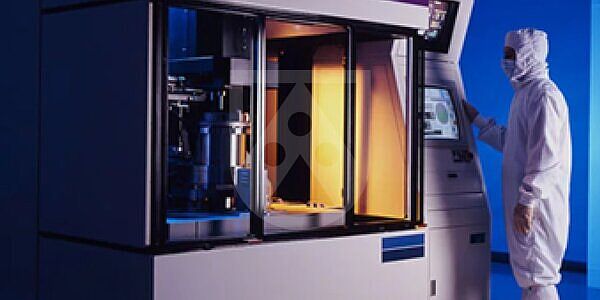

Trovidur® EC-FR White is tested in accordance with the specifications of FM 4910: “FM Approvals specification tested”. The PVC-U material meets the highest fire specifications in accordance with FM 4910 - perfect for safe and sustainable use in semiconductor and cleanroom technology applications. The material properties support employee safety, reduce contamination and help to reduce plant downtime.

Characteristics

- Clean Room Material

Industries

- Semiconductor factory equipment

- Semiconductor Front-End applications

- Semiconductor Front-End Wet Bench

Application Examples

We are proud to offer Trovidur® EC-FR, a PVC-U sheet, an FM4910 listed product from Germany for the promising semiconductor industry worldwide.

Christoph Zell - Product Manager Trovidur - E-Mail: czell@roechling.com

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stock item (no MOQ) | 458134 | Trovidur® EC-FR SD beige extruded | welding rod | welding rod | T-1013 ivory | Ø 4 mm | 4 mm | ||||

| No stock item (MOQ) | 469745 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | 6,1 x 3,1 mm | 6,1 mm | 3,1 mm | |||

| No stock item (MOQ) | 469747 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | Ø 3 mm | 3 mm | ||||

| No stock item (MOQ) | 475716 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | 5 x 3,5 mm | 5 mm | 3,5 mm | |||

| No stock item (MOQ) | 477789 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | Ø 3 x 1000 mm | 1 000 mm | 3 mm | |||

| No stock item (MOQ) | 477841 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | 1000 x 6,1 x 3,1 mm | 1 000 mm | 6,1 mm | 3,1 mm | ||

| Stock item (no MOQ) | 489482 | Trovidur® EC-FR SD white extruded | welding rod | welding rod | T-FR1130 white | Ø 4 mm | 4 mm | ||||

| Stock item (no MOQ) | 474140 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 6 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 6 mm | ||

| No stock item (MOQ) | 499473 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 15 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 15 mm | ||

| Stock item (no MOQ) | 499475 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 20 (-0/+1,4) x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 20 mm | ||

| Stock item (no MOQ) | 499844 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 10 (-0/+0,8) x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 10 mm | ||

| Stock item (no MOQ) | 509047 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 8 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 8 mm | ||

| Stock item (no MOQ) | 509050 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 12 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 12 mm | ||

| Stock item (no MOQ) | 509052 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 25 x 1000 x 2000 mm | 2 000 mm | 1 000 mm | 25 mm | ||

| Stock item (no MOQ) | 509070 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 30 x 1000 x 2000 mm | 2 000 mm | 1 000 mm | 30 mm | ||

| No stock item (MOQ) | 509071 | Trovidur® EC-FR white extruded | sheet | sheet | T-FR1130 white | 40 x 1000 x 2000 mm | 2 000 mm | 1 000 mm | 40 mm | ||

| No stock item (MOQ) | 458913 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 10 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 10 mm | ||

| No stock item (MOQ) | 458914 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 12 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 12 mm | ||

| No stock item (MOQ) | 458915 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 15 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 15 mm | ||

| No stock item (MOQ) | 458916 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 20 (-0/+1,4) x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 20 mm | ||

| No stock item (MOQ) | 460736 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 8 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 8 mm | ||

| No stock item (MOQ) | 469589 | Trovidur® EC-FR beige extruded | sheet | sheet | T-1013 ivory | 6 x 1500 x 3000 mm | 3 000 mm | 1 500 mm | 6 mm |

Technical Specifications Trovidur® EC-FR

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hustota | DIN EN ISO 1183-1 | g / cm3 | ∼1,46 |

| Absorpce vody | DIN EN ISO 62 | % | 0,2 |

| Protokol o zkoušce hořlavosti materiálů pro čisté prostory (tloušťka 6...40 mm) | FM 4910 | listed |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Mez kluzu | DIN EN ISO 527 | MPa | 50 |

| Prodloužení při přetržení | DIN EN ISO 527 | % | 20 |

| Modul pružnosti v tahu | DIN EN ISO 527 | MPa | 3000 |

| Vrubová houževnatost | DIN EN ISO 179 | kJ / m2 | 4 |

| Tvrdost Shore | DIN EN ISO 868 | scale D | 82 |

| Tvrdost kuličkového vtisku | DIN EN ISO 2039-1 | MPa | 115 |

| Pevnost v tlaku | DIN EN ISO 604 | MPa | 75 |

| Pevnost v ohybu | DIN EN ISO 178 | MPa | 80 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Tepelná vodivost | DIN EN ISO 8302 | W / (m * K) | 0,16 |

| Teplota měknutí dle Vicata | DIN EN ISO 306, dle Vicata B | °C | 75 |

| Provozní teplota | °C | -15 ... +60 | |

| Teplota tepelné deformace | DIN EN ISO 75 | °C | 70 |

| Koeficient lineární teplotní roztažnosti | DIN EN ISO 11359-2 | mm/m K | ∼0,075 |

| Teplota vznícení žhavého drátu | DIN EN 60695-2-13 | °C | 990 |

| Index hořlavosti žhavého drátu | DIN EN 60695-2-12 | °C | 960 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Relativní permitivita | IEC 60250 | ∼3,2 | |

| Dielektrický disipační faktor (106 Hz) | IEC 60250 | ∼0,02 | |

| Objemový odpor | DIN EN 62631-3-1 | Ω * cm | >1015 |

| Povrchový odpor | DIN EN 62631-3-2 | Ω | >1013 |

| Dielektrická pevnost | IEC 60243 | kV / mm | 12 |

| Srovnávací sledovací index | IEC 60112 | CTI | 600 |