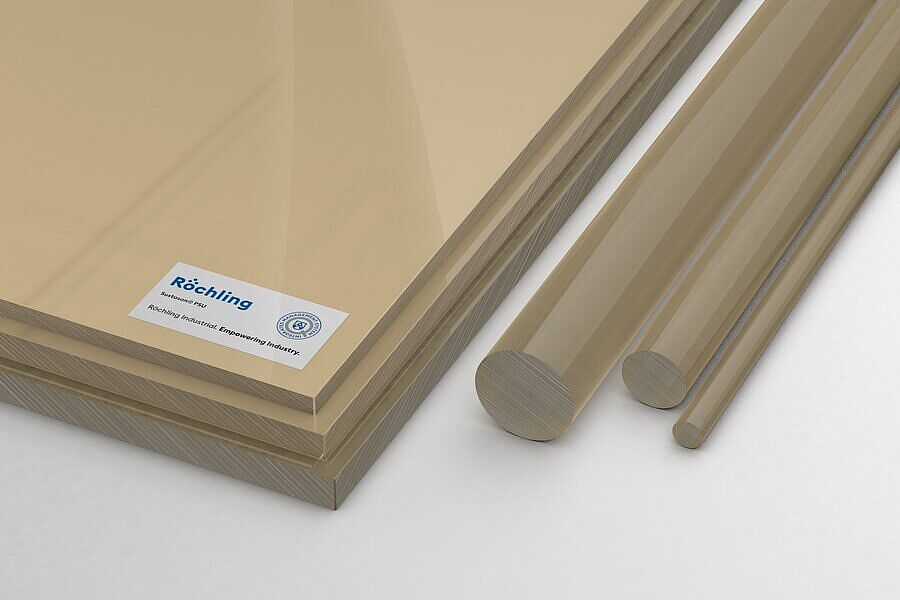

Sustason® PSU MG přírodní

PSU

Our specialist for pharmaceutical industry

Sustason® PSU MG was developed for the high requirements of the healthcare sector for transparent applications such as laboratory equipment, sight glasses or media-carrying components. Compared to PC, the plastic has a 42°C higher glass transition temperature and therefore in the temperature range from 130°C to 160°C a significantly higher strength. It is less sensitivity to stress cracking than PC, too. Furthermore, the amber-coloured transparency is better than that of other amorphous high-performance plastics (PEI, PPSU).

Characteristics

- Good sterilisation resistance

- High rigidity

- Good dimensional stability

- High continuous service temperature

- ISO 10993-5 tested on semi-finished product

- Good resistance against high energy radiation

- Good machinability

Industries

We are a system supplier and partner from the idea to the OEM's end product - as a cooperative value contribution. We are able to support the healthcare industry at the highest level.

Armin Reuner - Industry Manager Healthcare - Mail: AReuner@roechling.com

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 792987 | Sustason® PSU MG natural extruded | rod | rod | natural | Ø 50 x 3000 mm | 3 000 mm | 50 mm |

Technical Specifications Sustason® PSU MG natural

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hustota | DIN EN ISO 1183-1 | g / cm3 | 1,28 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Mez kluzu | DIN EN ISO 527 | MPa | 85 |

| Prodloužení při přetržení | DIN EN ISO 527 | % | 7 |

| Modul pružnosti v tahu | DIN EN ISO 527 | MPa | 2650 |

| Pevnost v tahu | DIN EN ISO 527 | MPa | 85 |

| Vrubová houževnatost | ISO 179-1/1eA | kJ / m2 | 2 |

| Tvrdost Shore | DIN EN ISO 868 | scale D | 83 |

| Tvrdost kuličkového vtisku (H358/30) | DIN EN ISO 2039-1 | MPa | 160 |

| Modul pružnosti v tlaku | DIN EN ISO 604 | MPa | 2250 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Teplota přechodu do skelného stavu | ISO 11357-3 | °C | 185 |