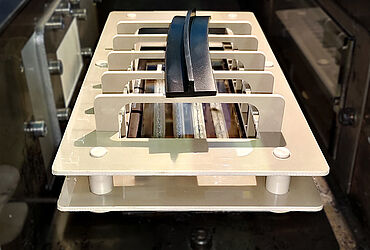

Conveyor technology & automation: saving energy with plastic

The transport of goods and merchandise within a company must be quick, reliable and economical. The use of materials with optimized slide properties in your conveying process helps to reduce the conveyor power required and with it the energy used. This in turns improves the performance and efficiency of your machines. We offer special materials for the manufacture of slide-optimized components for your plant and machinery in conveying and logistics processes.

Your advantages

- More economical production and logistics processes: Good slide friction reduces the conveyor energy required for your processes

- High process stability

- Efficient material flow

- Noise reduction

- Avoidance of slip-stick effects

Typical areas of application

- Beverage bottling systems

- Chain conveyors

- Automation

Application examples

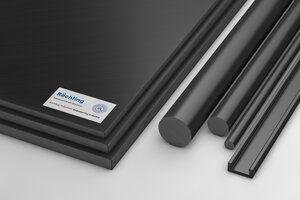

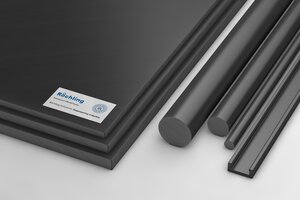

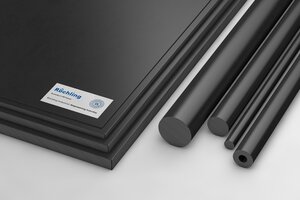

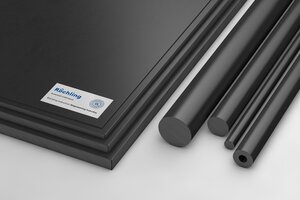

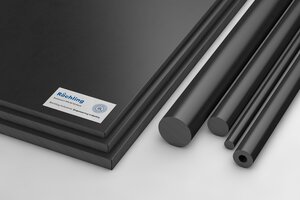

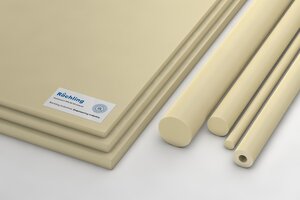

Related Products

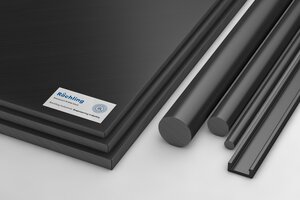

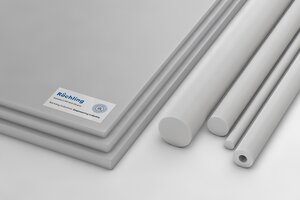

- PE > PE-UHMW - PE 1000

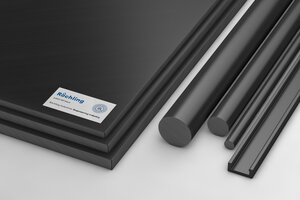

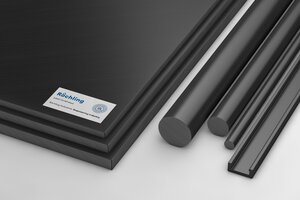

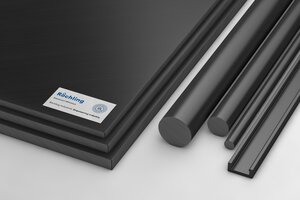

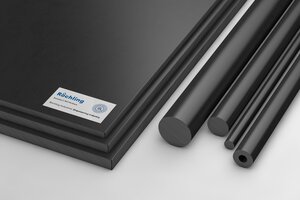

LubX® AST black

- PE > PE-UHMW - PE 1000

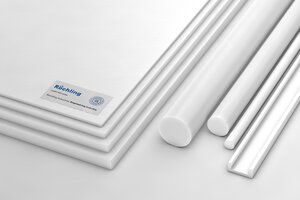

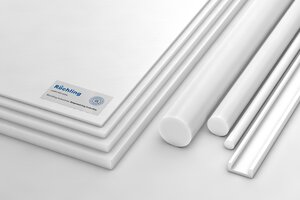

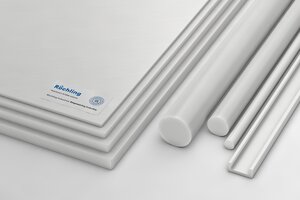

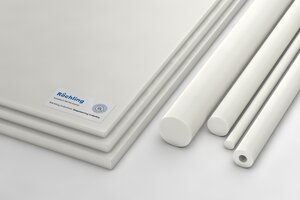

LubX® AST white

- PE > PE-UHMW - PE 1000

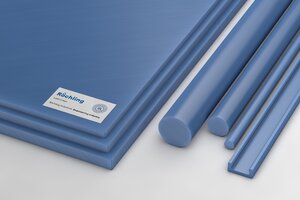

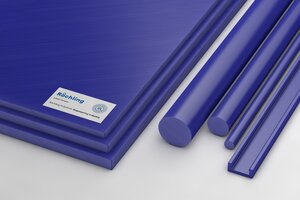

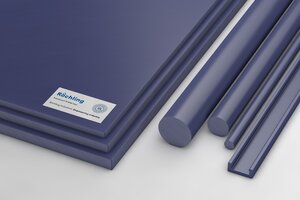

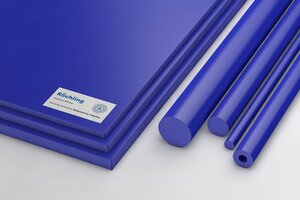

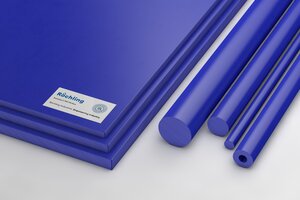

LubX® C blue

- PE > PE-UHMW - PE 1000

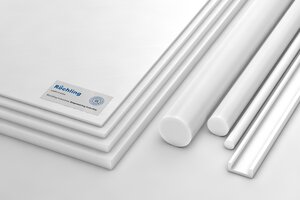

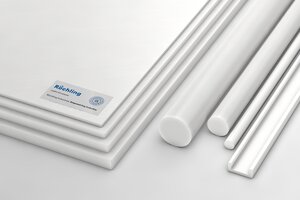

LubX® C natural

- PE > PE-UHMW - PE 1000

LubX® C white

- PE > PE-UHMW - PE 1000

LubX® CV AST black

- PE > PE-UHMW - PE 1000

LubX® CV AST white

- PE > PE-UHMW - PE 1000

LubX® CV blue

- PE > PE-UHMW - PE 1000

LubX® CV natural

- PE > PE-UHMW - PE 1000

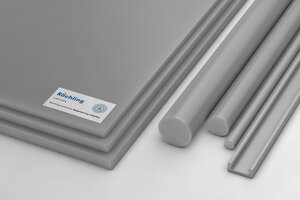

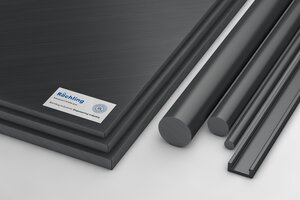

LubX® S grey

- PE > PE-HD - PE 500

Polystone® DR AST black

- PE > PE-HD - PE 500

Polystone® DR black

- PE > PE-HD - PE 500

Polystone® DR blue

- PE > PE-UHMW - PE 1000

Polystone® M AST + FDA black

- PE > PE-UHMW - PE 1000

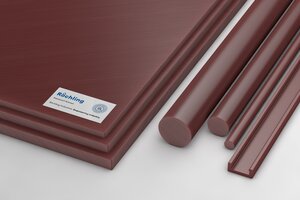

Polystone® M aubergine

- PE > PE-UHMW - PE 1000

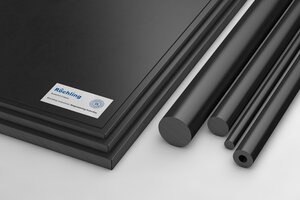

Polystone® M black

- PE > PE-UHMW - PE 1000

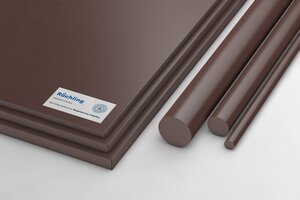

Polystone® M brown

- PE > PE-UHMW - PE 1000

Polystone® M EL + HI black

- PE > PE-UHMW - PE 1000

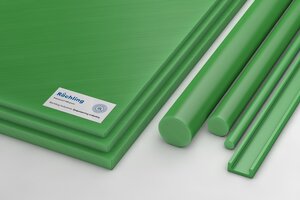

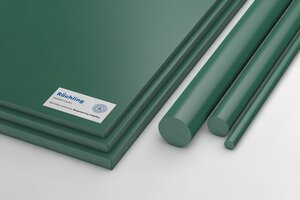

Polystone® M green

- PE > PE-UHMW - PE 1000

Polystone® M grey

- PE > PE-UHMW - PE 1000

Polystone® M natural

- PE > PE-UHMW - PE 1000

Polystone® M orange

- PE > PE-UHMW - PE 1000

Polystone® M red

- PE > PE-UHMW - PE 1000

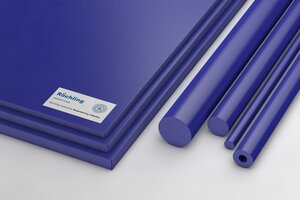

Polystone® M Saphir blue

- PE > PE-UHMW - PE 1000

Polystone® M Slide + AST black

- PE > PE-UHMW - PE 1000

Polystone® M Slide + AST grey

- PE > PE-UHMW - PE 1000

Polystone® M Slide black

- PE > PE-UHMW - PE 1000

Polystone® M Slide blue

- PE > PE-UHMW - PE 1000

Polystone® M Slide grey

- PE > PE-UHMW - PE 1000

Polystone® M Slide natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft white

- PE > PE-UHMW - PE 1000

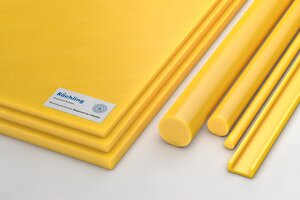

Polystone® M yellow pressed

- PE > PE-UHMW - PE 1000

Polystone® MPG black

- PE > PE-UHMW - PE 1000

Polystone® MPG blue

- PE > PE-UHMW - PE 1000

Polystone® MPG green

- PE > PE-UHMW - PE 1000

Polystone® MPG red

- PE > PE-UHMW - PE 1000

Polystone® MR AST black

- PE > PE-UHMW - PE 1000

Polystone® MR black

- PE > PE-UHMW - PE 1000

Polystone® MR green

- PA > PA 6

Sustamid® 6 FG natural

- PA > PA 6

Sustamid® 6 GC black

- PA > PA 6

Sustamid® 6 GC blue

- PA > PA 6

Sustamid® 6 GC natural

- PA > PA 6

Sustamid® 6 MO black

- PA > PA 6 G

Sustamid® 6G black

- PA > PA 6 G

Sustamid® 6G blue

- PA > PA 6 G

Sustamid® 6G green

- PA > PA 6 G

Sustamid® 6G grey

- PA > PA 6 G

Sustamid® 6G HS black

- PA > PA 6 G

Sustamid® 6G HS blue

- PA > PA 6 G

Sustamid® 6G HS natural

- PA > PA 6 G

Sustamid® 6G LU red

- PA > PA 6 G

Sustamid® 6G M grey

- PA > PA 6 G

Sustamid® 6G natural

- PA > PA 6 G

Sustamid® 6G OL black

- PA > PA 6 G

Sustamid® 6G OL blue

- PA > PA 6 G

Sustamid® 6G OL green

- PA > PA 6 G

Sustamid® 6G OL grey

- PA > PA 6 G

Sustamid® 6G OL natural

- PA > PA 6 G

Sustamid® 6G OL red

- PA > PA 6 G

Sustamid® 6G OL yellow

- PA > PA 6 G

Sustamid® 6G PD 120 blue

- PEEK

SustaPEEK MOD black

- POM-C

Sustarin® C BIO (mb)

- POM-C

Sustarin® C black

- POM-C

Sustarin® C blue

- POM-C

Sustarin® C brown

- POM-C

Sustarin® C GLD 350 blue

- POM-C

Sustarin® C green

- POM-C

Sustarin® C grey

- POM-C

Sustarin® C natural

- POM-C

Sustarin® C orange

- POM-C

Sustarin® C red

- POM-C

Sustarin® C white

- POM-C

Sustarin® C yellow

- POM-H

Sustarin® H black

- POM-H

Sustarin® H natural

- PA > PA 12 G

Lamigamid® 1200

- PA > PA 12 G

Lamigamid® 1207/1209

- PA > PA 12 G

Lamigamid® 1210

- PA > PA 12 G

Lamigamid® 1220

- PA > PA 6 G

Lamigamid® 320

- PA > PA 6 G

Lamigamid® 324/327

- PE > PE-UHMW - PE 1000

Polystone® M PIR natural

Product examples

See also

Arrange technical advice

The performance and service life of materials used in conveyor systems are influenced by a variety of factors. These factors must be taken into account in order to select the right materials. Examples:

- Mechanical loading

- Thermal loading

- Slide partner

- Contact with operating resources, parting agents, lubricants and detergents

- Design conditions, dimensions and tolerances

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.