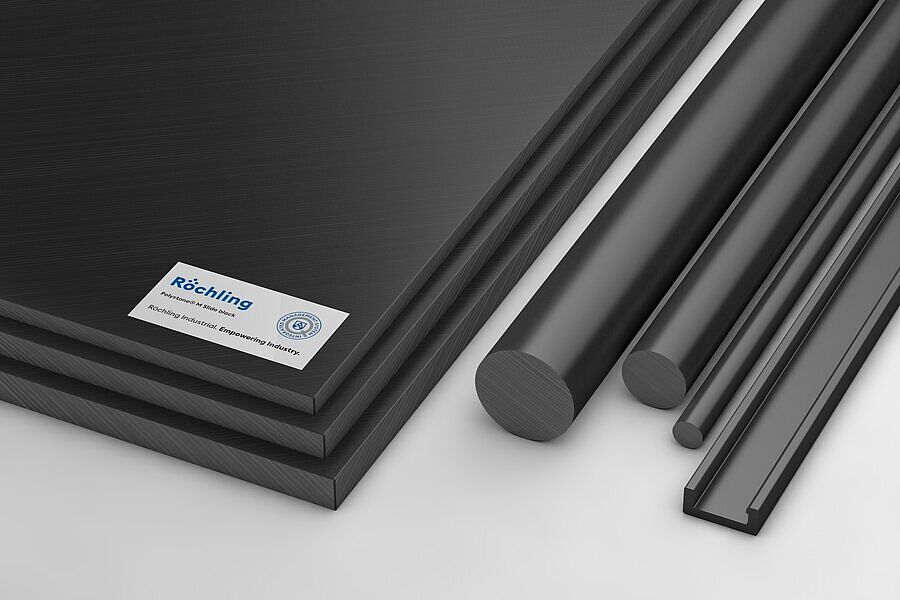

Polystone® M Slide black

PE — PE-UHMW - PE 1000

Polystone® M is an ultra-high molecular weight polyethylene (PE-UHMW/PE 1000) used to solve friction, wear and material flow problems in many industries. The material is characterized by excellent sliding properties, extreme wear resistance, high impact strength and very good resistance to chemicals and has established itself in technical applications. The material is available in various colors.

Characteristics

- Low coefficient of friction

- Noise-reducing

- Self-lubricating

- UV-resistant

- Good wear properties

Industries

- Food Industry

- Meat, Fish and Poultry Processing

- Beverage Industry

Sustainability

- LCA available (ISO 14040/44)

Application Examples

Technical Specifications Polystone® M Slide black

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | >0,95 |

| Water absorption | DIN EN ISO 62 | % | 0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Molecular weight | - | 106 g/mol | ∼ 9 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | >20 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >600 |

| Notched impact strength | DIN EN ISO 11542 | kJ / m2 | >110 |

| Shore hardness | DIN EN ISO 868 | scale D | >60 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 130 ... 135 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,40 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,90 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 ... 230 |

| Service temperature, long term | Average | °C | -250 … 80 |

| Service temperature, short term (max.) | Average | °C | 130 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 79 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | IEC 60250 | 2,3 | |

| Dielectric dissipation factor (106 Hz) | IEC 60250 | 0,0001 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |

| Comparative tracking index | IEC 60112 | 600 | |

| Dielectric strength | IEC 60243 | kV / mm | >40 |