Conveyor technology and automation: Saving energy with plastic.

The internal transport of goods and merchandise places high demands on speed, reliability and efficiency. Particularly in high-speed areas, plant operators must be able to rely on materials that can withstand the increasing load and environmental requirements. In order to work reliably, cost-efficiently and sustainably as a plant operator, you need innovative material solutions with coordinated sliding partners. Modern plastics with sliding-optimised properties help to reduce the required conveying force, lower energy consumption and increase the efficiency of the entire system.

Materials, products & production options

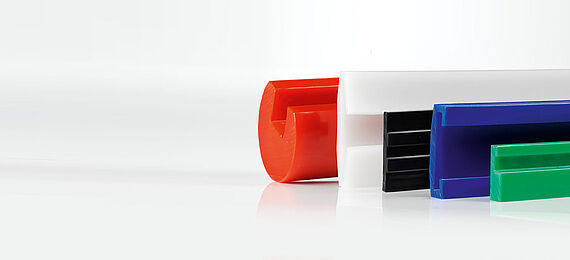

Our high-performance plastics optimise conveyor and logistics processes thanks to their excellent sliding properties and high load-bearing capacity. Whether as semi-finished products, finished parts or profiles - they impress with outstanding friction and wear resistance in a wide range of applications.

Further fields of application & industries

Our plastics are not only used in conveyor technology, but also in related industries such as lifts, lifts and the food industry. Their high performance and versatility make them the ideal solution for a wide range of applications.

Optimum sliding materials for your applications

The choice of the right sliding material influences the efficiency, durability and sustainability of conveyor systems. A holistic analysis of all influencing factors allows customised solutions to be developed for various industries - from the food industry to automation technology.

In addition to the friction partners, the ambient medium, temperature, pressure, movement sequence, conveying speed and the layout of the system play an important role.

Only by taking all influencing factors into account can an optimally suitable sliding material be selected for the respective application.

Mainly in sliding and conveying elements in conveyor technology. For example, in the beverage, packaging, pharmaceutical and food industries as well as in crane, lift and automation technology.

By reducing friction, Röchling products such as LubX® CV+ save energy in conveyor systems. We also rely on mass-balanced bioplastics that utilise bio-based raw materials - without compromising on performance.