Select a different country or region to see specific content for your location.

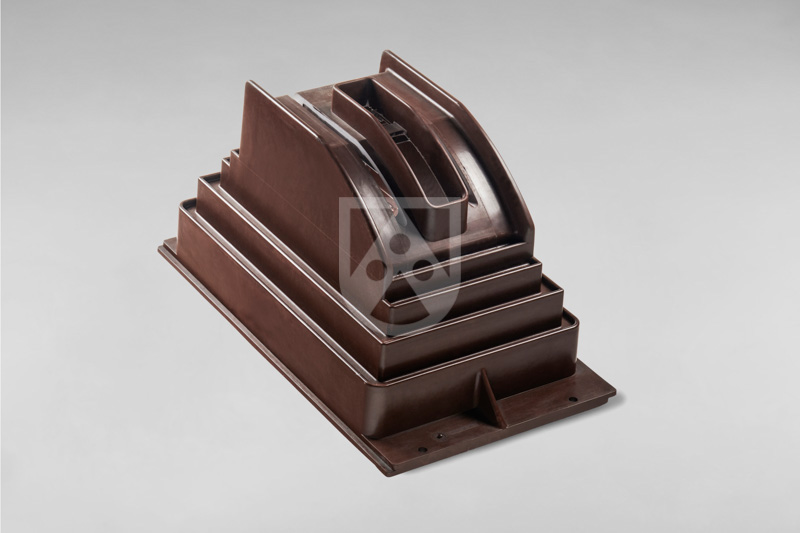

Compression moulded parts

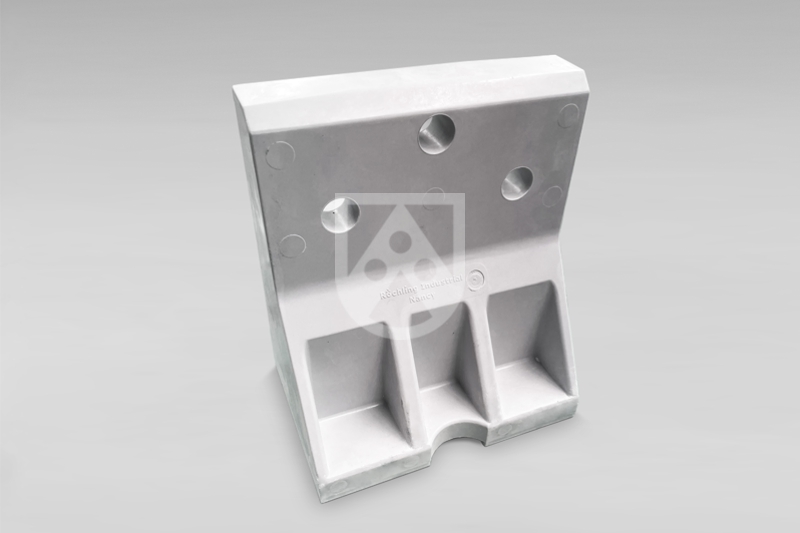

Durostone® Compression moulded parts

Durostone® Compression moulded parts - SMC Composites - BMC Composites

Components made of SMC (Sheet Molding Compound) and BMC (Bulk Molding Compound)

With modern presses and precise tools we produce the most varied FRP components and pressed parts from SMC and BMC-polyester products. In the SMC technique, a combination of resin and fibres is cured in a mould under pressure and heat. The production method enables time savings, high reproducibility and a smooth surface. The process is particularly suitable for medium-sized series.

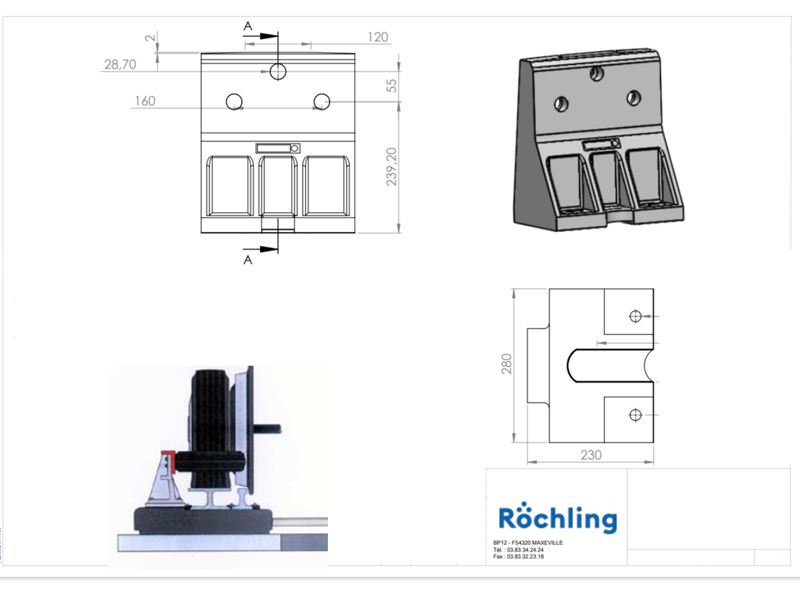

Dimensions

With our presses we are able to produce pressed parts (3-dimensional GRP) with dimensions of 150 x 150 x 150 mm up to 2200 x 1600 x 1200 mm.

Characteristics - Durostone® compression moulded parts

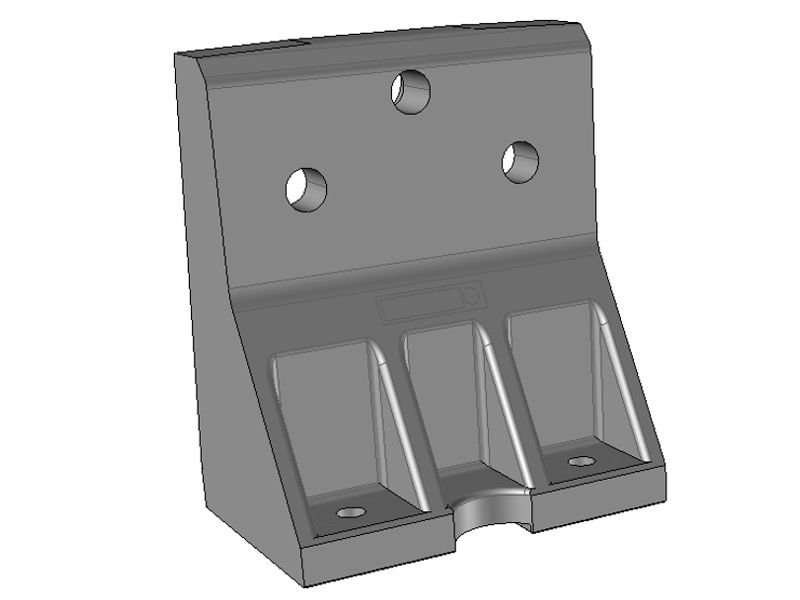

Product examples

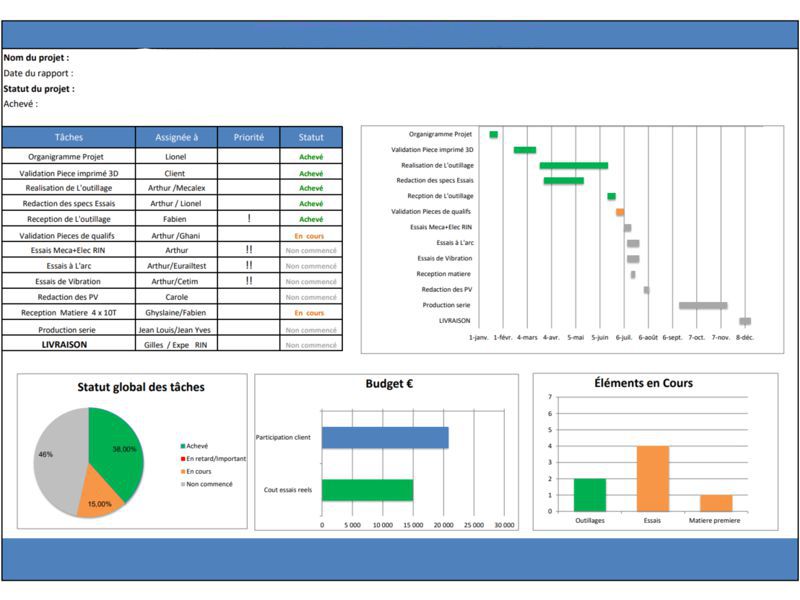

Project management

From planning to implementation, our experienced technicians will accompany you throughout the entire project. The result is apart manufactured to your specifications.

Initial Design

● Calculation by finite elements

● 3D printed prototype

Co-design & REX

● Eco-Design

● REX = Return Of eXperience

Visual planning

● Phases & Time

Production parts

● Tool reception / validation

● Dimensional reports