Safe on the racetrack with Sustavacu®

Röchling supplies material for the Formula Student

How do you develop, design and build an economical racing car that also impresses on the racetrack? To find out, students from different universities and colleges compete against each other every year in the Formula Student. The teams present their vehicles in the combustion engine, electric motor and autonomous driving competition classes. In "Emma", the new electric and autonomous racing car of the CURE Mannheim team of the DHBW Mannheim (Baden-Wuerttemberg Cooperative State University), components from Röchling Industrial were riding along for the first time.

Lightweight vehicle with high stiffness

The almost three-meter-long formula racing car weighs around 240 kilograms and reaches a speed of up to 110 kilometers per hour with 136 kW electric motors. To ensure that the car stays safely on the racetrack at these speeds, reinforcements made of Sustavacu® 6 GF in the rear and front wings ensure downforce while driving. “The material is perfect for our application. It has a very high stiffness, is tough and light. The goal is to build a vehicle that is as light as possible with a high level of stiffness,” explains Johannes Schindler, Team Leader Chassis & Composites, CURE Mannheim e.V.

The Formula Student is not just about speed. Aspects such as the engineering design, a business plan or the list of costs and production methods are also evaluated. The teams construct their racing car as a prototype, which is evaluated for production by industry experts. In the CURE Mannheim team, students from various disciplines work in small teams to take care of the powertrain, chassis, aerodynamics, electronics, chassis and driving dynamics of the racing car, as well as the organization and marketing of the team.

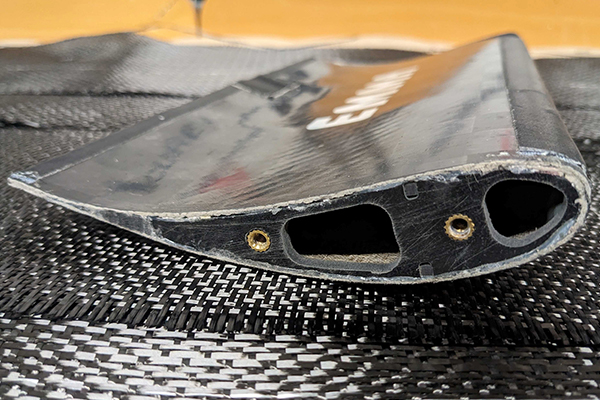

Wing elements made of SUSTAVACU® 6 GF

The team around Johannes Schindler is responsible for the chassis of the "Emma" racing car and installed the Sustavacu® 6 GF provided by Röchling Industrial Lahnstein. As endplates on the front and rear wings, coated with carbon-fibre-reinforced plastic, the material ensures extra stability with a low mass. The team designed the racing car virtually. The Sustavacu® 6 GF sheets are cut with a water jet cutting machine according to the construction. “The Sustavacu® 6 GF material is easy to machine and has a good weldability. In this way, the Formula Student engineers were able to insert threaded sleeves directly into the material without great effort in order to firmly connect the wing elements and chassis," explains Thomas Schölzel, Industry Manager Oil & Gas and responsible for Sustavacu® at Röchling Industrial Lahnstein.

In addition to Röchling Industrial, various partners from industry and business support the student racing teams.

The Formula Student

In the Formula Student, student teams from around the world compete against each other, and the team with the best racing car wins. The teams show their skills in three competition classes: "FS Combustion" (combustion engine), "FS Electric" (electric drive) or "FS Driverless" (autonomous driving, combustion engine or electric motor). The vehicle must demonstrate good acceleration, stable braking and high-performance handling in order to be able to travel safely and quickly on the racetrack. The teams also design their car with the ulterior motive of building a prototype that will be evaluated for series production. A jury of experts from motor sports, the automotive industry and the supplier industry assess the engineering approach, the costs and implementation of the vehicle, as well as the know-how that has flowed into it. The Formula Student gives students the opportunity to work in small, agile teams on time and project management, development, design and production, as well as the economic aspects of automotive engineering during their studies.