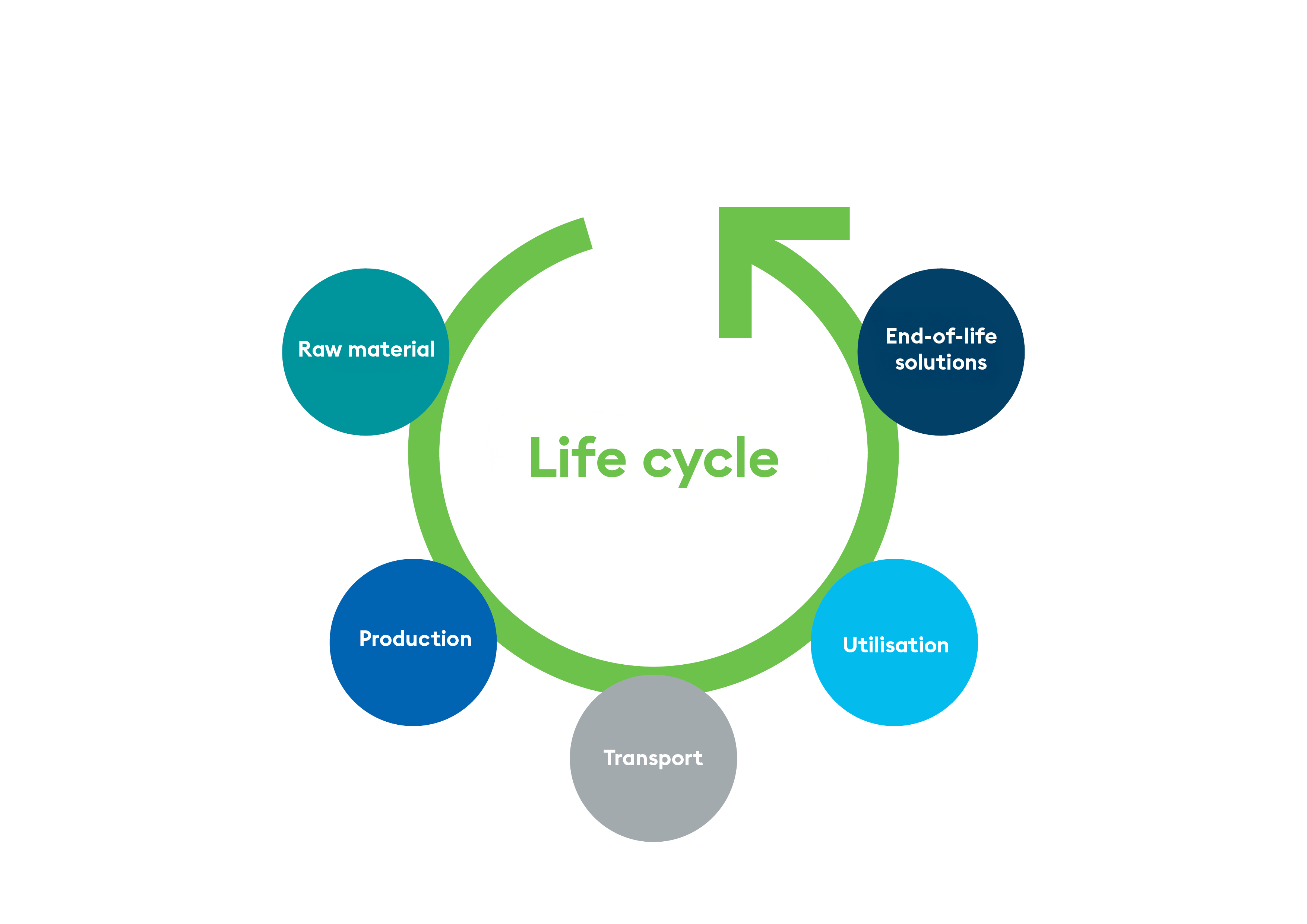

Life cycle

Every product consumes resources and has an environmental impact. Sustainability is not just a question of the raw material used, but also depends on factors such as use in the customer's application, service life and end-of-life options. A comprehensive assessment of these aspects over the entire life cycle (Life Cycle Assessment) is essential in order to evaluate the actual sustainability of a product. We have established an internal LCA process that complies with relevant standards and has been successfully verified by an independent auditing company.

Life cycle assessment

When considering products ecologically over their entire life cycle, the question arises: What makes a product sustainable?

According to the Deutsches Institut für Normung (German Institute for Standardisation), an environmentally sound product is one that complies with the required consumer benefit in comparison with conventional products, but uses fewer resources in production, use and disposal and has less impact on the environment. The useful life of the product must be taken into account in this regard.

The use of resources is associated with emissions and other environmental impacts. Considering these environmental impacts at every stage of the life cycle is part of a holistic environmental assessment.

The ecological consideration begins with the selection of the raw material used at the beginning of the product life cycle. Depending on the source material, different emissions and environmental impacts have to be taken into account. In doing so, the use of secondary raw materials that emerged from a previous product life cycle is more resource-efficient than primary raw materials that are newly extracted for the manufacture of a product.

The origin of the raw materials used also plays a role, because the longer the distances, the longer the transport routes that leave a significant ecological footprint in our world.

In addition, the manufacturing process has a significant impact on the environmental impact. The more energy-intensive the processing and production, the more resources are consumed and emissions are generated.

The careful use of resources of all kinds is one of our main goals. We continuously analyse and optimise our material cycles and energy flows. We focus on the use of sustainable raw materials.

A significant part of the life cycle of a product is the utilisation phase. It depends on the service life of a product. The more durable the product, the less often it needs to be replaced. In addition to uninterrupted use, this also contributes to saving resources in the form of spare parts.

We have been processing plastics for industrial applications for more than a hundred years. Based on this experience, we know that because of their special properties, fossil-based plastics contribute to the conservation of resources in many industries, e.g.:

- buses become lighter with our plastic components and then consume less fuel

- conveyor systems equipped with our sliding-optimised plastic components require less energy

- thermal insulation made of our plastics reduces the necessary heating times in machines and systems

A responsible use of resources includes recycling at the end of a product’s life cycle. Depending on material type, the possibilities can vary from material recycling to raw material processing to final thermal recycling for energy generation.

Thermoplastics are easy to recycle as they can be mechanically shredded and plastically reshaped within a certain temperature range. Many of our thermoplastics are recycled after use and reused for equivalent purposes.

In composite materials, separating the different composite materials usually involves a lot of effort and is difficult to achieve from an economic point of view. Nevertheless, new options are constantly being developed in this area as well. In the case of glass fibre-reinforced plastics, for instance, the glass fibres can be removed from the composite by thermal processes and used as filler material for further applications. This means that our composite materials can also serve as raw materials for future products after their use phase.

Life cycle assessment

Life cycle assessments (LCAs) are an established tool for assessing the environmental impact of a product along its life cycle. We have already created LCAs for many of our most important materials. The basis for this is a standardised LCA balancing process that was developed internally and verified externally by an independent auditing company. The verification confirms standard-compliant implementation and creates transparency in the preparation of LCAs.