Materiali plastici per l’ingegneria agraria

Per lavorare la terra in modo efficiente, gli agricoltori hanno bisogno di macchine agricole performanti e a bassa manutenzione. Che si tratti della semina, della potatura o del raccolto, l’agricoltore deve sempre poter fare affidamento sulle proprie macchine. Le macchine agricole sempre più grandi e pesanti aumentano il rischio di compattamento del suolo, con effetti negativi sulla flora e la fauna. Pertanto, per la costruzione di macchine agricole è necessario impiegare componenti leggeri e potenti. Da noi trovate materiali plastici, sviluppati appositamente per soddisfare questi requisiti: sono leggeri e, al tempo stesso, altamente resistenti all’usura e alla corrosione. Vi aiutano a migliorare l’efficienza e la durata della macchina. Rinomati produttori di macchine agricole e forestali in tutto il mondo si affidano ai nostri materiali.

From simple semi-finished products to complex finished parts

We offer tailor-made plastics with properties that often surpass traditional materials such as steel, wood or concrete and are therefore increasingly replacing these materials. There is hardly an industrial product that has not come into contact with, contains or consists of components made of plastic in its manufacturing process. The latest technology as well as modern production machinery allow us to be more broadly positioned concerning machining processes. Our manufacturing includes:

- easy cuts

- custom finished parts

- final execution through assembly services

Modernmachining processes

Milling

Oversized dimensions up to

12 m possible

Turning

Large turned

parts & pipes

Welding

Extrusion welding & Friction welding

Cutting

Panel sizing saws, band saws for round and hollow bars, circular plate saws

Automatic profile mill

no limitation of the processing length, difficult geometries possible, numerous processes combined

More processes

bending and creasing, drilling,

cutting, planing

Our innovations

We are always looking to further develop manufacturing techniques and create new solutions in order to keep up with the times. This is how we continuously build our customers‘ confidence with passion and common sense.

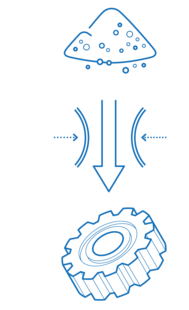

Press moulding

Precisely formed components in the highest material quality.

Plastic powder is transformed into three-dimensional plastic products without mechanical processing using heat and pressure. Thanks to unique hybrid technology, pure plastic parts can be reinforced with inserts (e.g. made of steel) to add stability.

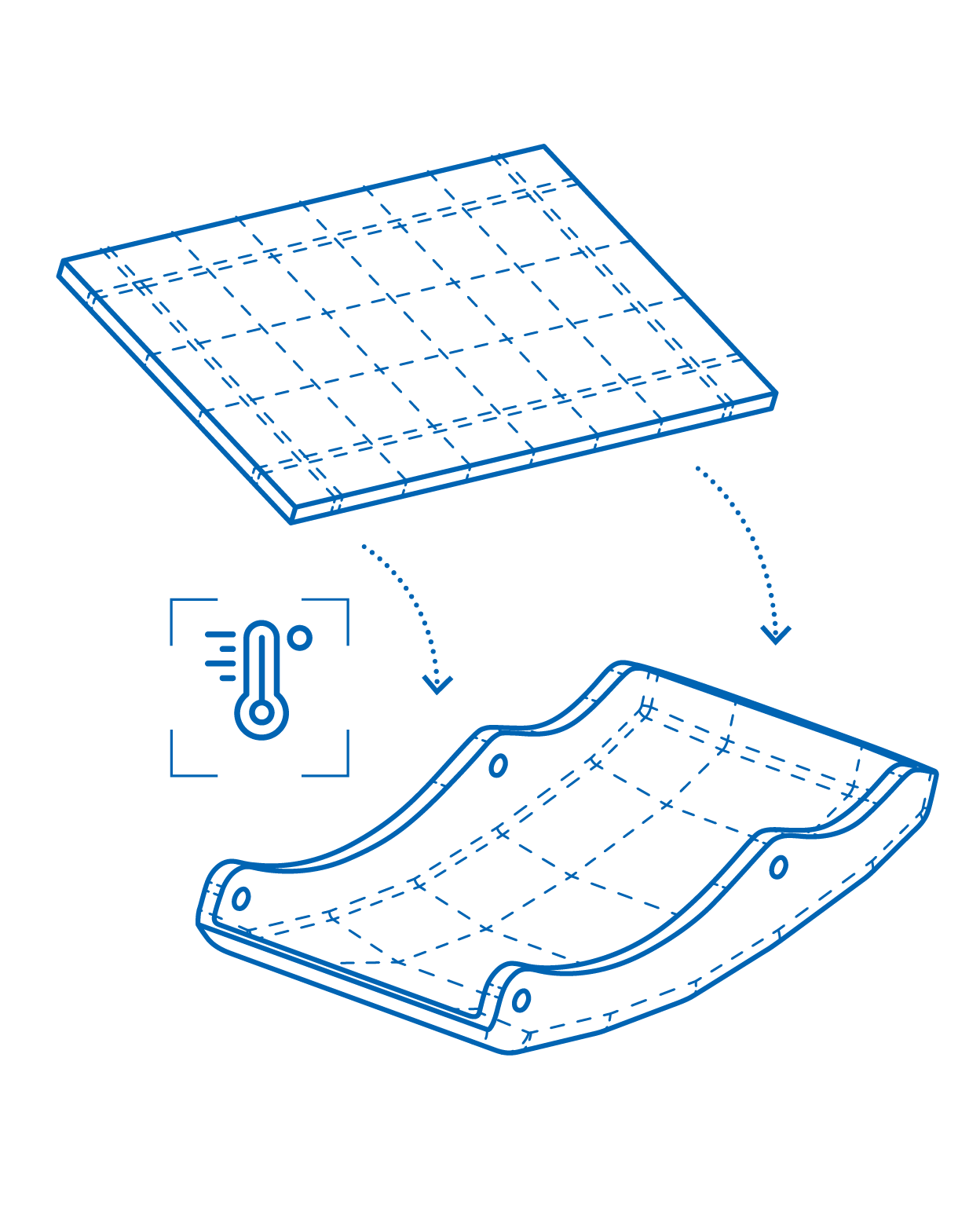

Thermoforming

Complex shaping simply implemented.

Thermoforming is a process that shapes ROBALON sheets using heat and vacuum. Two variants are available: one requires only a positive mold and a vacuum foil, often used in prototyping, while the other uses both upper and lower molds made of aluminum or steel for smooth production.

SmartMarker

The distinctive identifier for your product. SmartMarker is an innovative marker technology that clearly identifies individual components as belonging to a specific manufacturer. This means you can easily use a handheld scanner to check whether a component really comes from you, anytime and anywhere.

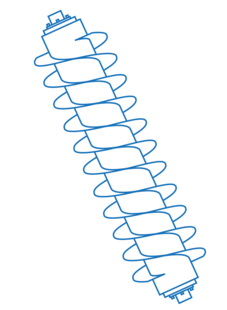

Screw production

Innovative development technology

Robalon screws are chemically resistant, corrosion-resistant, lightweight and have excellent sliding properties. Compared to steel alternatives, they are cost-effective and energy-efficient.

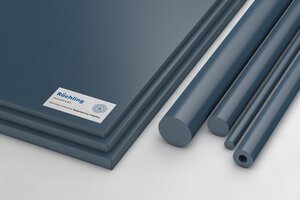

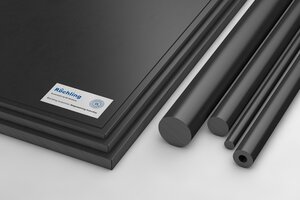

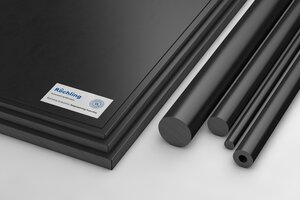

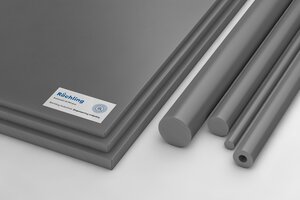

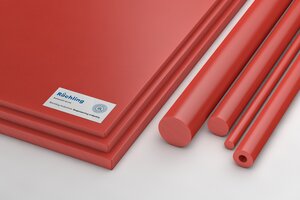

Our materials

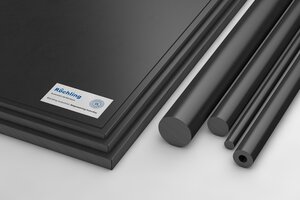

- PA > PA 6 G

Optamid®

- PA > PA 6 G

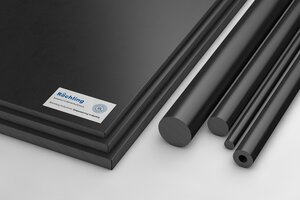

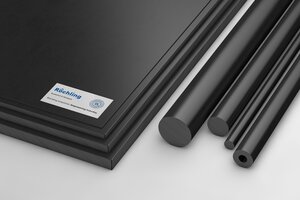

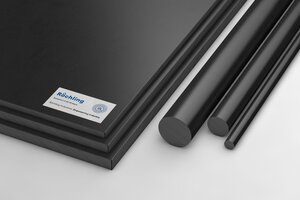

Sustaglide® black

- PA > PA 6 G

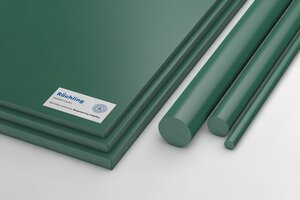

Sustaglide® green

- PA > PA 6 G

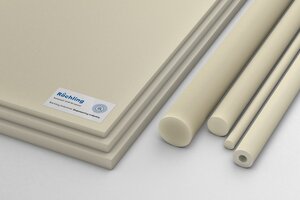

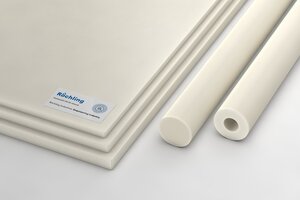

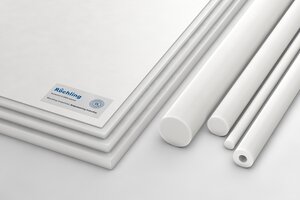

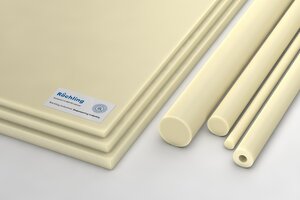

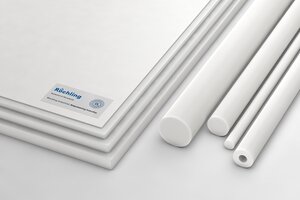

Sustaglide® natural

- PA > PA 12

Sustamid® 12 GF 30 natural

- PA > PA 12

Sustamid® 12 natural

- PA > PA 46

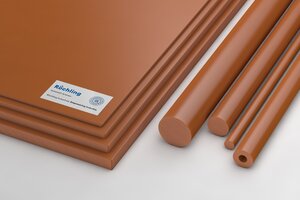

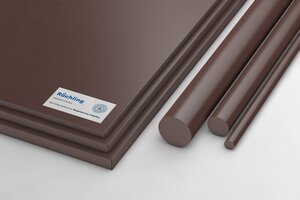

Sustamid® 46 brown

- PA > PA 6

Sustamid® 6 BIO (mb) natural

- PA > PA 6

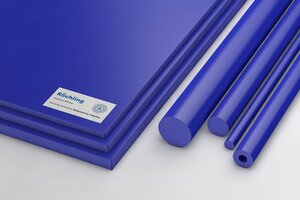

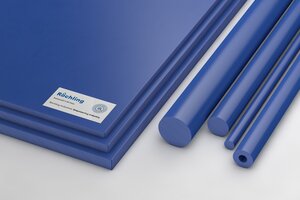

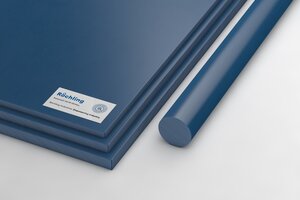

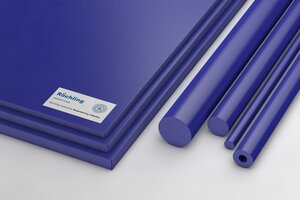

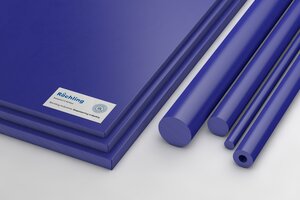

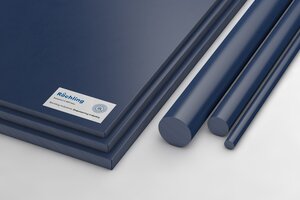

Sustamid® 6 blue

- PA > PA 6

Sustamid® 6 FG natural

- PA > PA 6

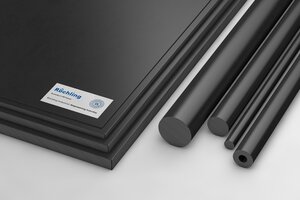

Sustamid® 6 FR black

- PA > PA 6

Sustamid® 6 FR natural

- PA > PA 6

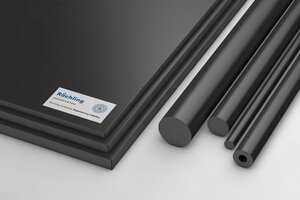

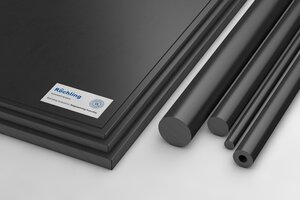

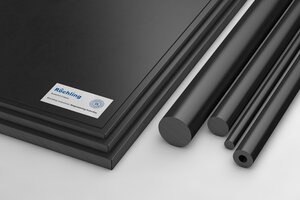

Sustamid® 6 GC black

- PA > PA 6

Sustamid® 6 GC blue

- PA > PA 6

Sustamid® 6 GC natural

- PA > PA 6

Sustamid® 6 GF 30 black

- PA > PA 6

Sustamid® 6 MO black

- PA > PA 6

Sustamid® 6 natural

- PA > PA 6

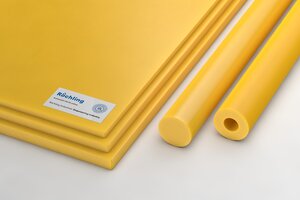

Sustamid® 6 orange

- PA > PA 6

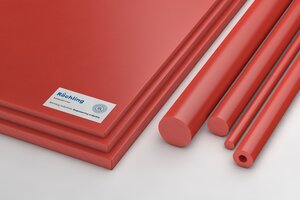

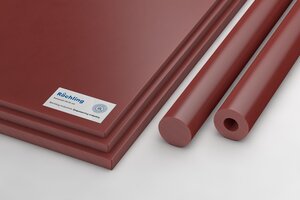

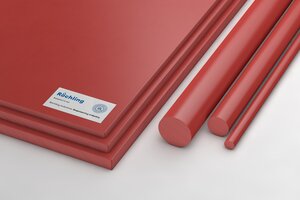

Sustamid® 6 red

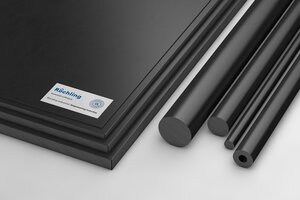

- PA > PA 66

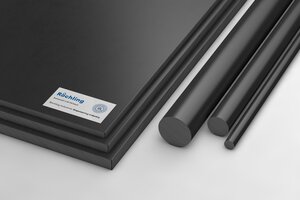

Sustamid® 66 black

- PA > PA 66

Sustamid® 66 GF 30 black

- PA > PA 66

Sustamid® 66 MO black

- PA > PA 66

Sustamid® 66 MO grey

- PA > PA 66

Sustamid® 66 natural

- PA > PA 66

Sustamid® 66 red

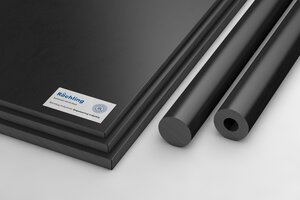

- PA > PA 6 G

Sustamid® 6G black

- PA > PA 6 G

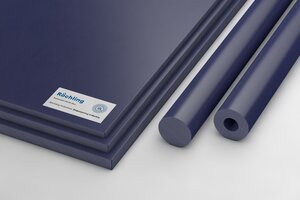

Sustamid® 6G blue

- PA > PA 6 G

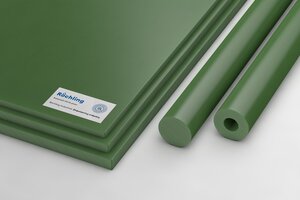

Sustamid® 6G green

- PA > PA 6 G

Sustamid® 6G grey

- PA > PA 6 G

Sustamid® 6G HS black

- PA > PA 6 G

Sustamid® 6G HS blue

- PA > PA 6 G

Sustamid® 6G LL natural

- PA > PA 6 G

Sustamid® 6G LU red

- PA > PA 6 G

Sustamid® 6G M grey

- PA > PA 6 G

Sustamid® 6G MO black

- PA > PA 6 G

Sustamid® 6G natural

- PA > PA 6 G

Sustamid® 6G OL black

- PA > PA 6 G

Sustamid® 6G OL blue

- PA > PA 6 G

Sustamid® 6G OL green

- PA > PA 6 G

Sustamid® 6G OL grey

- PA > PA 6 G

Sustamid® 6G OL natural

- PA > PA 6 G

Sustamid® 6G OL red

- PA > PA 6 G

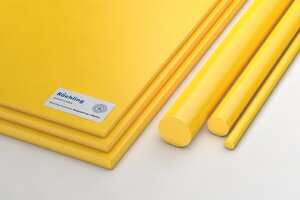

Sustamid® 6G OL yellow

- PA > PA 6 G

Sustamid® 6G PD 120 blue

- PA > PA 6 G

Sustamid® 6G PD 140 blue

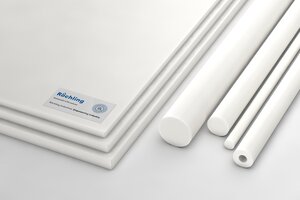

- POM-C

Sustarin® C BIO (mb)

- POM-C

Sustarin® C black

- POM-C

Sustarin® C blue

- POM-C

Sustarin® C brown

- POM-C

Sustarin® C DWS natural

- POM-C

Sustarin® C FG black

- POM-C

Sustarin® C FG blue

- POM-C

Sustarin® C FG natural

- POM-C

Sustarin® C GF 25 black

- POM-C

Sustarin® C GLD 350 blue

- POM-C

Sustarin® C green

- POM-C

Sustarin® C grey

- POM-C

Sustarin® C MDT blue

- POM-C

Sustarin® C natural

- POM-C

Sustarin® C orange

- POM-C

Sustarin® C red

- POM-C

Sustarin® C white

- POM-C

Sustarin® C yellow

- PA > PA 6

Sustavacu® 6 GF black

- PA > PA 12 G

Lamigamid® 1200

- PA > PA 12 G

Lamigamid® 1207/1209

- PA > PA 12 G

Lamigamid® 1209

- PA > PA 12 G

Lamigamid® 1210

- PA > PA 12 G

Lamigamid® 1220

- PA > PA 6 G

Lamigamid® 300

- PA > PA 6 G

Lamigamid® 304

- PA > PA 6 G

Lamigamid® 307

- PA > PA 6 G

Lamigamid® 309

- PA > PA 6 G

Lamigamid® 310

- PA > PA 6 G

Lamigamid® 312

- PA > PA 6 G

Lamigamid® 312 blue

- PA > PA 6 G

Lamigamid® 314

- PA > PA 6 G

Lamigamid® 317

- PA > PA 6 G

Lamigamid® 318

- PA > PA 6 G

Lamigamid® 319

- PA > PA 6 G

Lamigamid® 320

- PA > PA 6 G

Lamigamid® 324/327

- PA > PA 6 G

Lamigamid® 339

- PA > PA 6 G

Lamigamid® 400B

- PA > PA 6 G

Lamigamid® 450N

- POM-C

Sustarin® C ID blue

- POM-C

Sustarin® C PIR black

Discover our innovative & sustainable product families

As a family company, we at Röchling stand for value-based and sustainable action. We treat the environment and society as we do our customers, partners and employees: with mutual respect, great regard and considerable trust. We divide our focus topics into the three fields of action Products, People, Planet.

Your contact person for

inquiries and more information

Thomas Meisinger