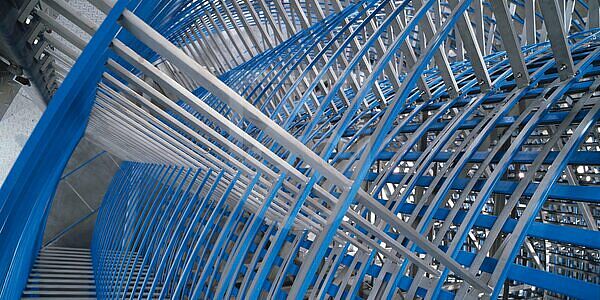

Application Examples

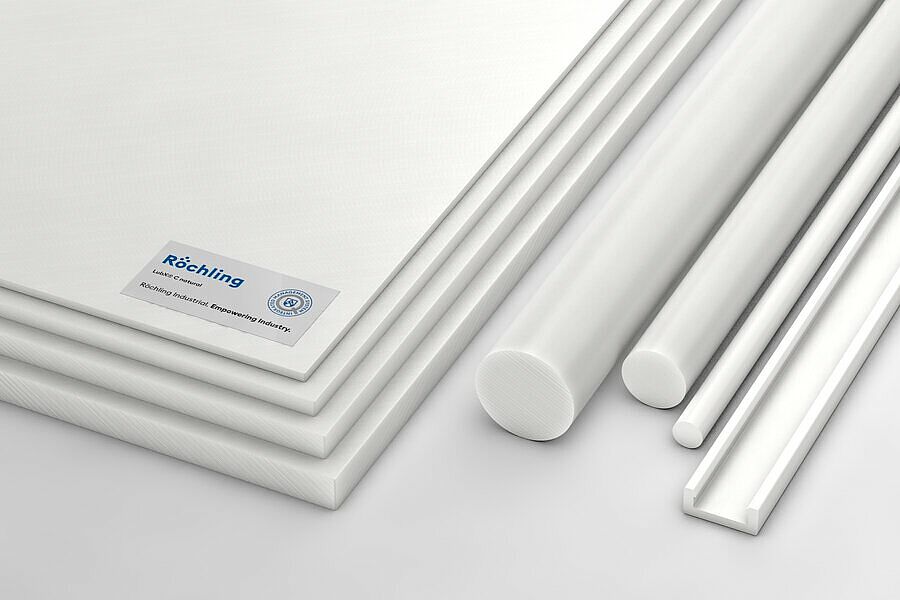

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 437440 | LubX® C natural extruded | (R740) | 25.000 x 15,5 x 7,2 mm | 25.000 mm | 15,5 mm | 7,2 mm | ||||

| No stock item (MOQ) | 441228 | LubX® C natural extruded | (R746) | 25.000 x 14,7 x 8 mm | 25.000 mm | 14,7 mm | 8 mm | ||||

| No stock item (MOQ) | 441240 | LubX® C natural extruded | (R741) | 25.000 x 17,5 x 8 mm | 25.000 mm | 17,5 mm | 8 mm | ||||

| No stock item (MOQ) | 441247 | LubX® C natural extruded | (R743) | 25.000 x 8,5 x 6 mm | 25.000 mm | 8,5 mm | 6 mm | ||||

| No stock item (MOQ) | 441278 | LubX® C natural extruded | (R744) | 3000 x 23 x 7 mm | 3.000 mm | 23 mm | 7 mm | ||||

| No stock item (MOQ) | 441368 | LubX® C natural extruded | (R745) | 25.000 x 10,2 x 6,2 mm | 25.000 mm | 10,2 mm | 6,2 mm | ||||

| No stock item (MOQ) | 441465 | LubX® C natural extruded | (R747) | 3000 x 27,5 x 13,4 mm | 3.000 mm | 27,5 mm | 13,4 mm | ||||

| No stock item (MOQ) | 441475 | LubX® C natural extruded | (R748) | 3000 x 15,7 x 13,4 mm | 3.000 mm | 15,7 mm | 13,4 mm | ||||

| No stock item (MOQ) | 441966 | LubX® C natural extruded | (R749) | 25.000 x 22 x 7,2 mm | 25.000 mm | 22 mm | 7,2 mm | ||||

| No stock item (MOQ) | 463787 | LubX® C natural extruded | (R790) | 3000 (-0/+15) x 55 x 11,5 mm | 3.000 mm | 55 mm | 11,5 mm | ||||

| No stock item (MOQ) | 465118 | LubX® C natural extruded | (R792) | 50.000 x 13,3 x 6 mm | 50.000 mm | 13,3 mm | 6 mm | ||||

| No stock item (MOQ) | 465843 | LubX® C natural extruded | (R543) | 50.000 x 15,81 x 5,8 mm | 50.000 mm | 15,81 mm | 5,8 mm | ||||

| No stock item (MOQ) | 467896 | LubX® C natural extruded | (R793) | 25.000 x 14 x 6 mm | 25.000 mm | 14 mm | 6 mm |

Technical Specifications LubX® C natural

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,93 |

| Water absorption | DIN EN ISO 62 | % | <0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Non-toxicity | + | ||

| Moulding Compound PE | DIN ISO 1872-1 | UHMW-PE-QCD 35-3-4 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Sliding properties: partner POM (0,25 m/s - 0,25 MPa) | REP - Tribology - Test | 0,08 | |

| Sliding properties: partner POM (0,25 m/s - 0,25MPa) | REP - Tribology - Test | 0,11 | |

| Yield stress | DIN EN ISO 527 | MPa | 19 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 500 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | no break |

| Shore hardness | DIN EN ISO 868 | scale D | 60 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 133 – 135 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 - 230 (*) |

| Service temperature, long term | Average | °C | -150 … 80 (*) |

| Service temperature, short term (max.) | Average | °C | 130 (*) |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume resistivity | DIN EN 62631-3-1 | Ohm * cm | >1015 |

| Surface resistivity | DIN EN 62631-3-2 | Ohm | >1014 |