Plastics for efficient and dependable Galvanic plants

Investing in new galvanic plants is always a major challenge for companies in the chemical processing industry. The plants must not only be up and running in a timely manner but also be highly efficient and dependable in the long term. Manufacturers of these plants must take into account numerous factors such as the appropriate electroplating technology, operating temperatures, chemical media, and construction materials that provide the highest level of process stability and operational reliability.

Above all, it is essential that the plant remains efficient and safe to operate, even in the face of aggressive chemicals, high operating temperatures, and extended service life. That's where our specially developed plastics come in. They are designed for contact with various chemicals, capable of withstanding different usage temperatures, and are easy to process. Our plastics help build reliable and process-safe plants. We are happy to advise on selecting the right materials for your specific application.

Your advantages

- High process safety

- Low-maintenance facilities

- Suitable for high permanent usage temperatures

- High resilience against the media used in the process

Typical areas of application

- Galvanic systems for treatment of metal parts, car raw shell and plastic parts

- Copper coating systems

- Chrome-plating systems

Polystone® P flex

Polystone® P flex combines very good elasticity with good chemicals resilience and can at the same time be welded to PP. Thus, thermal and mechanical expansions can be compensated for in a targeted manner during construction already - e.g. spaces in process tanks in galvanic or steel staining systems.

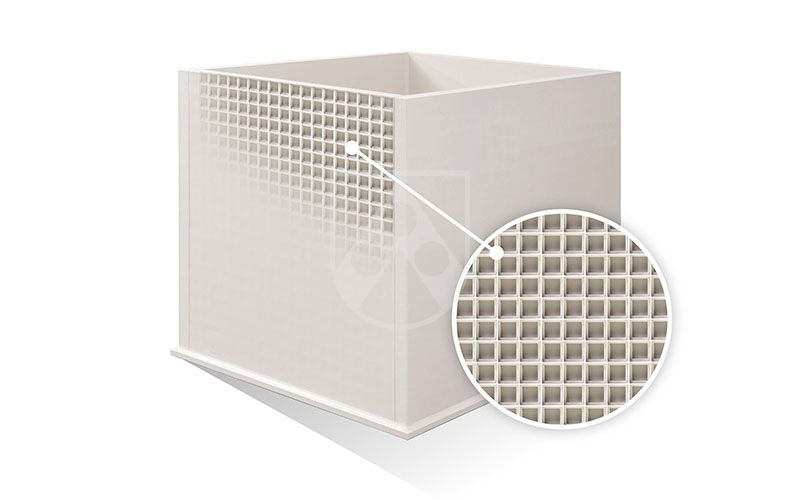

Polystone® P CubX®

Polystone® P CubX® is a tank construction sheet featuring a unique inner cube structure developed for rectangular tanks. The innovative design combines light weight and ease of handling with very high longitudinal and transverse rigidity. Depending on the size of the tank, steel reinforcements can be completely or significantly reduced. The time savings in tank construction is enormous.

More information about Polystone® P CubX®

Arrange technical advice

The performance and reliability of materials for galvanic plants are influenced by a variety of factors. These criteria need to be considered in order to make the right choice. Examples:

- Composition and concentration of the chemical media

- Usage temperature

- Mechanical stress

- Design of the tank

- Construction conditions

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.