Durostone® FRP Rebar High performance reinforcement bars

For corrosion-free, high strength, durable and very economic structures

Durostone® FRP Rebar - with CE approval. The new generation of fibre-reinforced composite reinforcement bars. Combine extremely high strengths with low weight and longer service life. Specially developed for demanding applications that require high mechanical stability and corrosion resistance from reinforcement bars. Available as:

- Durostone® GFRP Rebar – Glass-fibre-reinforced plastic (GFRP)

FRP REBAR

Fiber Reinforced Polymer Reinforcement Bar

Reference projects

For demanding fields of application

Durostone® FRP Rebars were especially developed for demanding fields of application in aggressive environments, where reinforcement bars have to withstand permanently high mechanical and corrosive loads. Durostone® FRP Rebars have outstanding properties for such requirements. For example:

Corrosion resistance

Alkali-resistance & durability

Chemical resistance

Easy machinability

No conductivity & no frequency disturbance

High tensile strength & minimum component thickness

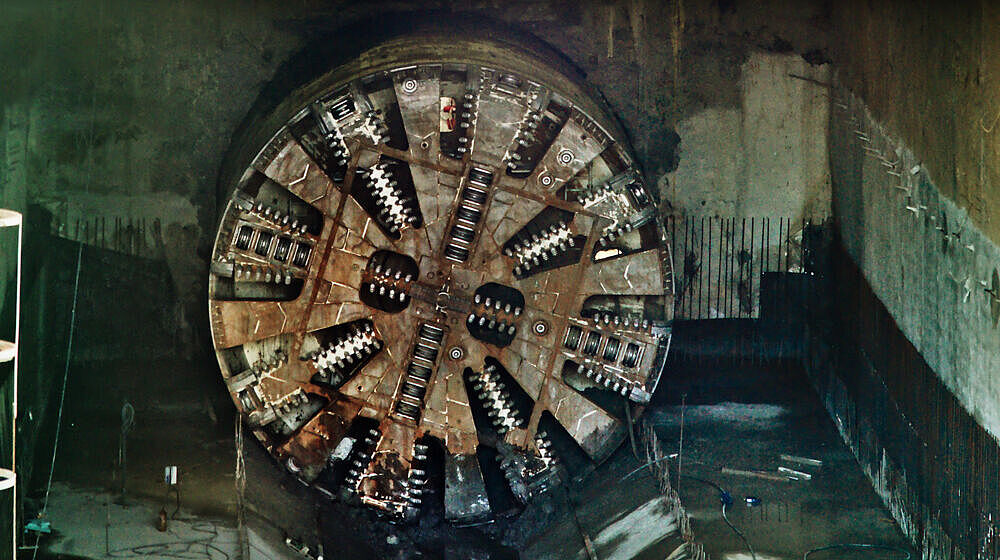

Port of Miami tunnel project

Project Tangier – Morocco

High corrosion resistance – No rust

- Permanent alkali and chemical resistance and high acid resistance, also in very demanding environments

- Resistant to concrete carbonation and in the event of acidic impact, e. g. aggressive mountain water or industrial waste water

- Prevents concrete spalling and protects static structural parts

High economic efficiency – Reduction of lifecycle costs

- Significantly reduced maintenance and service life costs

- Considerably lower to no repair and replacement costs

- More quality, but no higher construction costs; instead, savings potential compared to steel

- Cost reduction of structures through minimal requirements for concrete covering (rod diameter + 10 mm), through possible use of conventional concrete qualities or through elimination of expensive additives and protective coatings

- Up to fourfold savings in transport costs due to 73 % lower deadweight

Greater mechanical stability with low weight – High strength

- Enormous tensile strength and first class durability of mechanical properties

- Very good bond strength properties for ideal force transmission

- Lightweight material with only 27 % of the weight of steel

- Minimised deadweight of concrete structures. Permits filigree structures

- Much easier and less dangerous handling on building sites

High safety and functionality

- No electric or electromagnetic conductivity

- No magnetism and no disruption of sensitive electronic installations

- Transparent for radar and radio waves

- Very low heat conductivity, as a result avoidance of thermal bridges

- Easy machinability. Easy cutting properties of the reinforcement prevents damage to tools and machinery in civil engineering and tunnel construction

Long service life and extremely high quality – Sustainable

High quality corrosion resistant fibres and highly durable quality resins and the precise Durostone® FRP Rebar manufacturing process ensure outstanding qualities and an innovative building material with uniquely bundled properties

Sturdy, durable composite reinforcement in concrete

Much longer service life for heavily stressed structures

Production range

- Standard sizes: 8 mm, 10 mm, 13 mm, 16 mm, 19 mm, 25 mm, 32 mm

- Other tailor-made sizes available on request