Plastics for safe water treatment

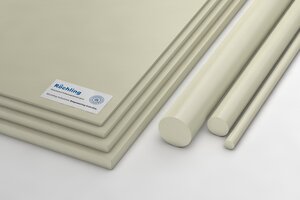

Fresh, clean water is a precious commodity. The efficient sourcing and treatment of water is vital for our quality of life. Sodium hypochlorite, chlorine and ozone are among the aggressive chemicals used for treatment. Installations must be able to withstand these influences for the long term. We offer plastics that are designed specifically for these requirements: they have a high resistance to chemicals, have the necessary purity for contact with drinking water and are easy to process. You can use them to design safe and long-lasting installations. We offer a complete system comprising of sheets, U and hollow profiles, welding rods and the RITA tank construction programme.

Your advantages

- High operational reliability thanks to very high resistance to chemicals

- Long service life because of high resistance to wear and tear

- Lightweight for easy installation

- Compliance with standard guidelines: KTW requirements, EU Directive 10/2011, FDA, RoHS

- Suitable for outdoor use thanks to high UV resistance

- Very easy to weld and process

Typical areas of application

- Chemical water treatment

- Purification systems

- Mini purification systems

- Drinking water tanks

- Wastewater treatment

- Fountains, fountain linings

- Sea water desalination plants

- Industrial (cooling) water treatment plants

- PE > PE-HD (PE 100)

Polystone® G CubX® black

- PE > PE-HD - PE 300

Polystone® G Pipe Grade - ASTM

- PE > PE-HD - PE 300

Polystone® G Utility black - ASTM

- PE > PE-HD - PE 300

Polystone® G virgin black - ASTM

- PE > PE-HD - PE 300

Polystone® G virgin natural - ASTM

- PE > PE-HD - PE 300

Polystone® G virgin UV-stabilized natural - ASTM

- PVC-U

Trovidur® EC N black

Arrange technical advice

The performance and service life of materials used for water treatment are influenced by a variety of factors. These factors must be taken into account in order to select the right materials. Examples:

- Chemical type

- Contact with drinking water

- UV radiation

- Static and dynamic loading

- Design conditions, dimensions and tolerances

We are happy to advise on the selection of suitable materials for your particular application. Please submit an inquiry via the contact form below.

Our complete range for containers and plant engineering

We offer a complete range of plate material, plastic filler wires, hollow sections and U-sections plus our RITA container computation software for the production of containers and systems. Sheets, filler wires, hollow sections and U-sections are made from the same moulding compound. This results in identical material properties and the best processability of the entire container.

![[Translate to English Unites States:] [Translate to English Unites States:]](/fileadmin/_processed_/1/e/csm_Roechling_Schweissdraht_35dc3d7e7b.jpg)

![[Translate to English Unites States:] [Translate to English Unites States:]](/fileadmin/_processed_/8/0/csm_Roechling_Behaelterbau_c6b02c038b.jpg)