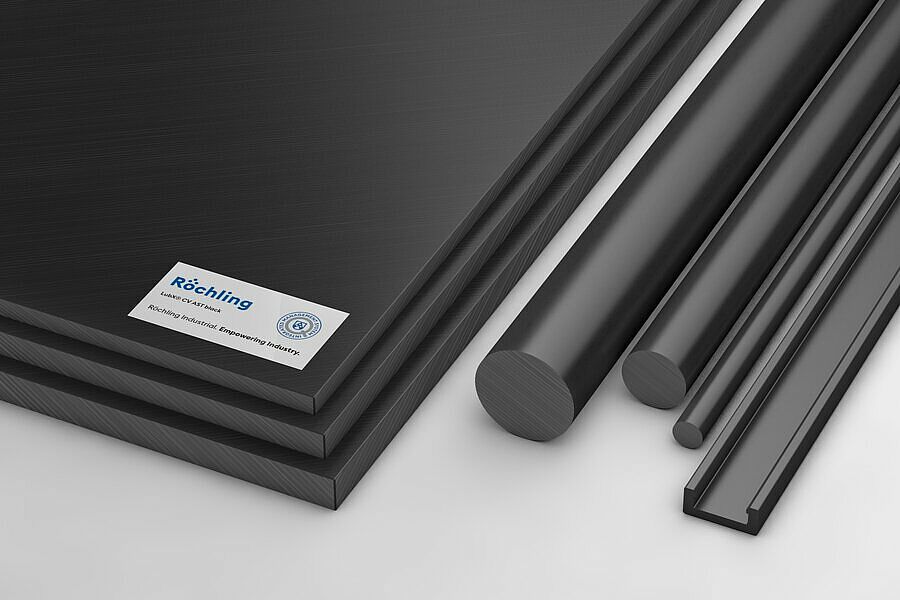

LubX® CV AST black

PE — PE-UHMW - PE 1000

The antistatic sliding material LubX® AST combines excellent tribological properties with controlled electrostatic dissipation and is specifically designed for machines in conveying systems that have to be operated at high speeds.

- In comparison to standard antistatic materials for machine construction, LubX® AST, with a sliding friction coefficient of µ: 0.19, offers more than 30% better sliding properties.

- In combination with permanent antistatic properties, LubX® AST improves the economic efficiency of your transport processes and allows controlled dissipation.

black, similar RAL 9005

sheet

Characteristics

- Antistatic

- Good sliding properties

- Excellent dry-running properties

- Good wear resistance

- Food contact approvals

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 435544 | LubX® CV AST black pressed | sheet | sheet | black, similar RAL 9005 | 2000 x 1000 x 8 mm | 2.000 mm | 1.000 mm | 8 mm | ||

| No stock item (MOQ) | 436760 | LubX® CV AST black pressed | sheet | sheet | black, similar RAL 9005 | 6000 x 2000 x 8 mm | 6.000 mm | 2.000 mm | 8 mm |

Technical Specifications LubX® CV AST black

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,95 |

| Water absorption | DIN EN ISO 62 | % | <0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Non-toxicity | + | ||

| Moulding Compound PE | DIN ISO 1872-1 | UHMW-PE-QCD 35-3-4 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Sliding properties: partner POM (0,25 m/s - 0,25 MPa) | REP - Tribology - Test | 0,13 | |

| Yield stress | DIN EN ISO 527 | MPa | 17 |

| Elongation at yield stress | DIN EN ISO 527 | % | 14 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 750 |

| Impact strength | DIN EN ISO 179 | kJ / m2 | 50 |

| Shore hardness | DIN EN ISO 868 | scale A | 60 |

| Shore hardness | DIN EN ISO 868 | scale D | 60 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 133 ... 135 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 ... 230 (*) |

| Service temperature, long term | Average | °C | -150 ... 80 (*) |

| Service temperature, short term (max.) | Average | °C | 130 (*) |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume resistivity | DIN EN 62631-3-1 | Ohm * cm | ≥109 |

| Volume resistivity | DIN EN 62631-3-1 | Ohm * cm | ≤109 |

| Surface resistivity | DIN EN 62631-3-2 | Ohm | ≥109 |