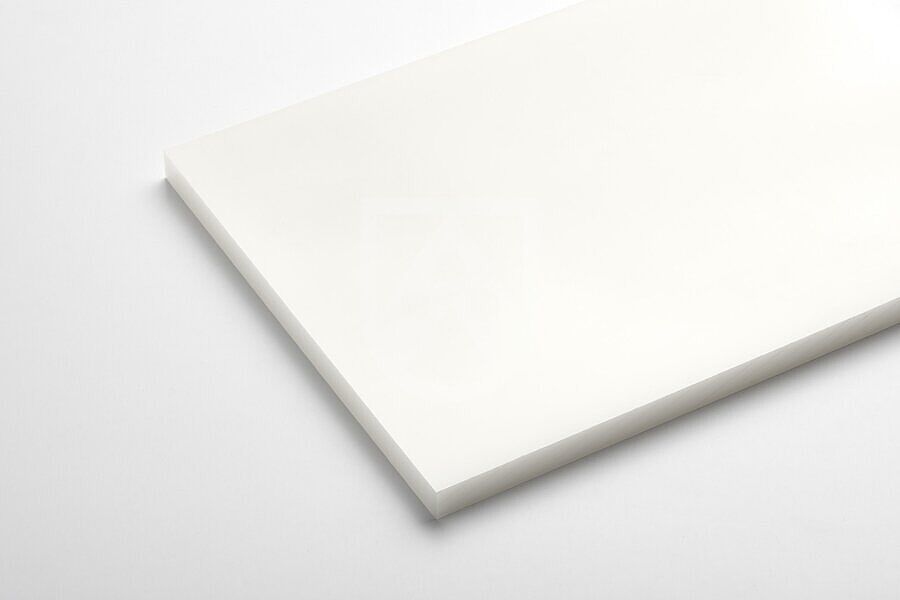

| Stock item (no MOQ) | 100418 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 1 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

1 mm

| | |

| Stock item (no MOQ) | 100419 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 2 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

2 mm

| | |

| Stock item (no MOQ) | 100420 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 3 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

3 mm

| | |

| Stock item (no MOQ) | 100421 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 4 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

4 mm

| | |

| Stock item (no MOQ) | 100422 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 5 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

5 mm

| | |

| Stock item (no MOQ) | 100423 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 6 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

6 mm

| | |

| Stock item (no MOQ) | 100424 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 8 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

8 mm

| | |

| Stock item (no MOQ) | 100425 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 10 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

10 mm

| | |

| Stock item (no MOQ) | 100426 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 12 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

12 mm

| | |

| Stock item (no MOQ) | 100427 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 15 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 302626 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 6 x 1000 x 4000 mm |

4.000 mm

|

1.000 mm

|

6 mm

| | |

| No stock item (MOQ) | 381837 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 8 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

8 mm

| | |

| No stock item (MOQ) | 466680 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 2 (-0,1/+0,2) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

2 mm

| | |

| No stock item (MOQ) | 475469 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 2 x 1000 x 1000 (-5/+0) mm |

1.000 mm

|

1.000 mm

|

2 mm

| | |

| No stock item (MOQ) | 478083 | Polystone® D natural extruded |

sheet

|

sheet

| natural | 5 x 1250 x 2000 mm |

2.000 mm

|

1.250 mm

|

5 mm

| | |

| No stock item (MOQ) | 929486 | Polystone® D natural extruded |

rod

|

rod

| natural | Ø 80 x 3000 mm |

3.000 mm

| |

80 mm

| | |

| Stock item (no MOQ) | 101062 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

10 mm

| | |

| Stock item (no MOQ) | 101063 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

12 mm

| | |

| Stock item (no MOQ) | 101064 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

15 mm

| | |

| Stock item (no MOQ) | 101065 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

20 mm

| | |

| Stock item (no MOQ) | 101066 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

25 mm

| | |

| Stock item (no MOQ) | 101067 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

30 mm

| | |

| Stock item (no MOQ) | 101068 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

35 mm

| | |

| Stock item (no MOQ) | 101069 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

40 mm

| | |

| Stock item (no MOQ) | 101070 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

50 mm

| | |

| Stock item (no MOQ) | 101071 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

60 mm

| | |

| Stock item (no MOQ) | 101072 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

70 mm

| | |

| Stock item (no MOQ) | 101073 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

80 mm

| | |

| Stock item (no MOQ) | 101074 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

90 mm

| | |

| Stock item (no MOQ) | 101075 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

100 mm

| | |

| Stock item (no MOQ) | 101076 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 150 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

150 mm

| | |

| Stock item (no MOQ) | 101077 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

8 mm

| | |

| Stock item (no MOQ) | 101078 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

10 mm

| | |

| Stock item (no MOQ) | 101079 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

12 mm

| | |

| Stock item (no MOQ) | 101080 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

15 mm

| | |

| Stock item (no MOQ) | 101081 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

20 mm

| | |

| Stock item (no MOQ) | 101082 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

25 mm

| | |

| Stock item (no MOQ) | 101083 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

30 mm

| | |

| Stock item (no MOQ) | 101084 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

35 mm

| | |

| Stock item (no MOQ) | 101085 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

40 mm

| | |

| Stock item (no MOQ) | 101086 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

50 mm

| | |

| Stock item (no MOQ) | 101087 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

60 mm

| | |

| Stock item (no MOQ) | 101088 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

10 mm

| | |

| Stock item (no MOQ) | 101089 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

12 mm

| | |

| Stock item (no MOQ) | 101090 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

15 mm

| | |

| Stock item (no MOQ) | 101091 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

20 mm

| | |

| Stock item (no MOQ) | 101092 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

25 mm

| | |

| Stock item (no MOQ) | 101093 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 210514 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1250 x 2000 mm |

2.000 mm

|

1.250 mm

|

20 mm

| | |

| No stock item (MOQ) | 210615 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

100 mm

| | |

| No stock item (MOQ) | 211693 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 211729 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 (-0/+0,4) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 211730 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 (-0/+0,4) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

25 mm

| | |

| No stock item (MOQ) | 211731 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 211732 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 (-0/+0,4) x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 211769 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 (-0/+0,4) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 211770 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 (-0/+0,4) x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 211857 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 (-0/+0,6) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

50 mm

| | |

| No stock item (no MOQ) | 212916 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

8 mm

| | |

| No stock item (no MOQ) | 212917 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

45 mm

| | |

| No stock item (MOQ) | 212918 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 55 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

55 mm

| | |

| No stock item (MOQ) | 212920 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 110 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

110 mm

| | |

| No stock item (MOQ) | 212921 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 120 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

120 mm

| | |

| No stock item (MOQ) | 212922 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 212923 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 212925 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

8 mm

| | |

| Stock item (no MOQ) | 212926 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

40 mm

| | |

| Stock item (no MOQ) | 212927 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 212928 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 212930 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 218461 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 65 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

65 mm

| | |

| No stock item (MOQ) | 218462 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 75 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

75 mm

| | |

| No stock item (MOQ) | 218463 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 95 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

95 mm

| | |

| No stock item (MOQ) | 218464 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

60 mm

| | |

| No stock item (no MOQ) | 218465 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

45 mm

| | |

| No stock item (MOQ) | 224107 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 224108 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

100 mm

| | |

| No stock item (MOQ) | 226526 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 226631 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

8 mm

| | |

| No stock item (MOQ) | 229151 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 140 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

140 mm

| | |

| No stock item (MOQ) | 229152 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 234236 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

35 mm

| | |

| No stock item (MOQ) | 236010 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 239339 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 130 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

130 mm

| | |

| No stock item (MOQ) | 240752 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 240755 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 240760 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

20 mm

| | |

| No stock item (MOQ) | 241907 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1000 x 4000 mm |

4.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 242481 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 2000 mm |

2.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 242772 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

70 mm

| | |

| No stock item (MOQ) | 242804 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

70 mm

| | |

| No stock item (MOQ) | 242993 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

10 mm

| | |

| No stock item (MOQ) | 246443 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 200 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

200 mm

| | |

| No stock item (MOQ) | 246456 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 18 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

18 mm

| | |

| No stock item (MOQ) | 246750 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 16 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

16 mm

| | |

| No stock item (MOQ) | 247417 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

80 mm

| | |

| No stock item (MOQ) | 247720 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 1500 x 3000 mm |

3.000 mm

|

1.500 mm

|

30 mm

| | |

| No stock item (MOQ) | 247898 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 249236 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 16 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

16 mm

| | |

| No stock item (MOQ) | 251461 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 1000 x 1000 mm |

1.000 mm

|

1.000 mm

|

100 mm

| | |

| No stock item (MOQ) | 252952 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

60 mm

| | |

| No stock item (MOQ) | 252956 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

100 mm

| | |

| No stock item (MOQ) | 253036 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

10 mm

| | |

| No stock item (MOQ) | 253615 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

25 mm

| | |

| No stock item (MOQ) | 253644 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 (-0/+0,4) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

45 mm

| | |

| No stock item (MOQ) | 253815 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 254810 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 18 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

18 mm

| | |

| No stock item (MOQ) | 255815 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

10 mm

| | |

| No stock item (MOQ) | 256270 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

70 mm

| | |

| No stock item (MOQ) | 256483 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 130 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

130 mm

| | |

| No stock item (MOQ) | 256632 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 257056 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

80 mm

| | |

| No stock item (MOQ) | 257071 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

100 mm

| | |

| No stock item (MOQ) | 257932 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

10 mm

| | |

| No stock item (MOQ) | 262720 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1250 (-0/) x 2000 mm |

2.000 mm

|

1.250 mm

|

40 mm

| | |

| No stock item (no MOQ) | 262918 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

80 mm

| | |

| No stock item (MOQ) | 262967 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 22 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

22 mm

| | |

| No stock item (MOQ) | 264084 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

90 mm

| | |

| No stock item (MOQ) | 264085 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 120 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

120 mm

| | |

| No stock item (MOQ) | 265783 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

45 mm

| | |

| No stock item (MOQ) | 267036 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 32 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

32 mm

| | |

| No stock item (MOQ) | 268166 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 1000 x 1000 mm |

1.000 mm

|

1.000 mm

|

60 mm

| | |

| No stock item (MOQ) | 268451 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 125 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

125 mm

| | |

| No stock item (MOQ) | 269202 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 1000 x 1000 mm |

1.000 mm

|

1.000 mm

|

80 mm

| | |

| No stock item (MOQ) | 270768 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

25 mm

| | |

| No stock item (MOQ) | 273698 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

40 mm

| | |

| No stock item (MOQ) | 276747 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

12 mm

| | |

| No stock item (MOQ) | 276816 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

12 mm

| | |

| No stock item (MOQ) | 276818 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 23 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

23 mm

| | |

| No stock item (MOQ) | 276819 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 31 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

31 mm

| | |

| No stock item (MOQ) | 276820 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

35 mm

| | |

| No stock item (MOQ) | 276822 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

60 mm

| | |

| No stock item (MOQ) | 276823 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

70 mm

| | |

| No stock item (MOQ) | 276824 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

80 mm

| | |

| No stock item (MOQ) | 276825 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 120 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

120 mm

| | |

| No stock item (MOQ) | 276826 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

60 mm

| | |

| No stock item (MOQ) | 276827 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

70 mm

| | |

| No stock item (MOQ) | 276828 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

90 mm

| | |

| No stock item (MOQ) | 276915 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

15 mm

| | |

| No stock item (MOQ) | 276916 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

30 mm

| | |

| No stock item (MOQ) | 276917 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

50 mm

| | |

| No stock item (MOQ) | 276918 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

60 mm

| | |

| No stock item (MOQ) | 276944 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

25 mm

| | |

| No stock item (MOQ) | 276970 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

100 mm

| | |

| No stock item (MOQ) | 277115 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

35 mm

| | |

| No stock item (MOQ) | 277116 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

8 mm

| | |

| No stock item (MOQ) | 277172 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 22 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

22 mm

| | |

| No stock item (MOQ) | 277173 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

45 mm

| | |

| No stock item (MOQ) | 277174 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 110 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

110 mm

| | |

| No stock item (MOQ) | 277175 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 150 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

150 mm

| | |

| No stock item (MOQ) | 277176 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 55 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

55 mm

| | |

| No stock item (MOQ) | 277177 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 65 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

65 mm

| | |

| No stock item (MOQ) | 277178 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 75 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

75 mm

| | |

| No stock item (MOQ) | 277480 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

90 mm

| | |

| No stock item (MOQ) | 277539 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

70 mm

| | |

| No stock item (MOQ) | 277660 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 16 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

16 mm

| | |

| No stock item (MOQ) | 277690 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 85 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

85 mm

| | |

| No stock item (MOQ) | 277799 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 16 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

16 mm

| | |

| No stock item (MOQ) | 277859 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 13 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

13 mm

| | |

| No stock item (MOQ) | 277905 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 160 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

160 mm

| | |

| No stock item (MOQ) | 277915 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

45 mm

| | |

| No stock item (MOQ) | 277965 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 18 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

18 mm

| | |

| No stock item (MOQ) | 278011 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

90 mm

| | |

| No stock item (MOQ) | 278086 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

80 mm

| | |

| No stock item (MOQ) | 278219 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 32 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

32 mm

| | |

| No stock item (MOQ) | 278352 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 42 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

42 mm

| | |

| No stock item (MOQ) | 280280 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

12 mm

| | |

| No stock item (MOQ) | 284117 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

35 mm

| | |

| No stock item (MOQ) | 284469 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 170 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

170 mm

| | |

| No stock item (MOQ) | 286570 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2000 x 2000 mm |

2.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 294317 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 294319 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 (-0/+0,4) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 294322 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 (-0/+0,6) x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 295589 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 160 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

160 mm

| | |

| No stock item (MOQ) | 300251 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 2000 x 2000 mm |

2.000 mm

|

2.000 mm

|

25 mm

| | |

| No stock item (MOQ) | 302727 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1000 x 3000 mm |

3.000 mm

|

1.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 307899 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 85 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

85 mm

| | |

| No stock item (MOQ) | 311479 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 140 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

140 mm

| | |

| No stock item (MOQ) | 315965 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 75 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

75 mm

| | |

| No stock item (MOQ) | 316718 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

10 mm

| | |

| No stock item (MOQ) | 317129 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

45 mm

| | |

| No stock item (MOQ) | 317576 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 1000 x 4000 mm |

4.000 mm

|

1.000 mm

|

30 mm

| | |

| No stock item (MOQ) | 322622 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

12 mm

| | |

| No stock item (MOQ) | 322623 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

15 mm

| | |

| No stock item (MOQ) | 322625 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

20 mm

| | |

| No stock item (MOQ) | 322627 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

25 mm

| | |

| No stock item (MOQ) | 322628 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

30 mm

| | |

| No stock item (MOQ) | 322629 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

40 mm

| | |

| No stock item (MOQ) | 322630 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

8 mm

| | |

| No stock item (MOQ) | 323340 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 2000 mm |

2.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (no MOQ) | 323677 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

12 mm

| | |

| No stock item (no MOQ) | 323679 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

20 mm

| | |

| No stock item (no MOQ) | 323685 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

25 mm

| | |

| No stock item (no MOQ) | 323697 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

15 mm

| | |

| No stock item (no MOQ) | 323698 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

40 mm

| | |

| No stock item (no MOQ) | 323699 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 (-0/+0,6) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

50 mm

| | |

| No stock item (no MOQ) | 323703 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

30 mm

| | |

| No stock item (no MOQ) | 323704 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 (-0/+0,4) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

10 mm

| | |

| No stock item (no MOQ) | 323770 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 60 (-0/+0,6) x 1220 (-0/) x 2000 (-0/) mm |

2.000 mm

|

1.220 mm

|

60 mm

| | |

| No stock item (MOQ) | 324378 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1500 x 2000 mm |

2.000 mm

|

1.500 mm

|

50 mm

| | |

| No stock item (MOQ) | 328674 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 65 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

65 mm

| | |

| No stock item (MOQ) | 330404 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 55 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

55 mm

| | |

| No stock item (MOQ) | 332169 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1000 x 1000 mm |

1.000 mm

|

1.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 333857 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90 x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

90 mm

| | |

| No stock item (MOQ) | 334272 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 75 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

75 mm

| | |

| No stock item (MOQ) | 335944 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 8 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

8 mm

| | |

| No stock item (MOQ) | 337043 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 10 x 2000 x 2000 mm |

2.000 mm

|

2.000 mm

|

10 mm

| | |

| No stock item (MOQ) | 338085 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 72 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

72 mm

| | |

| No stock item (MOQ) | 349397 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 130 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

130 mm

| | |

| No stock item (MOQ) | 351226 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 5000 mm |

5.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 352525 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1000 x 6000 mm |

6.000 mm

|

1.000 mm

|

50 mm

| | |

| No stock item (MOQ) | 371807 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50,3 (-0/+0,6) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

50,3 mm

| | |

| No stock item (MOQ) | 371862 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 51 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

51 mm

| | |

| No stock item (MOQ) | 373090 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 25 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

25 mm

| | |

| No stock item (MOQ) | 373092 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 373094 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 373095 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

12 mm

| | |

| No stock item (MOQ) | 386417 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 72 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

72 mm

| | |

| No stock item (MOQ) | 409773 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 (-0/+0,6) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

50 mm

| | |

| No stock item (MOQ) | 411845 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 35 (-0/+0,4) x 1250 (+/-30) x 6000 mm |

6.000 mm

|

1.250 mm

|

35 mm

| | |

| No stock item (MOQ) | 417730 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1250 (+/-30) x 2000 mm |

2.000 mm

|

1.250 mm

|

40 mm

| | |

| No stock item (MOQ) | 417732 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 50 x 1250 (+/-30) x 2000 mm |

2.000 mm

|

1.250 mm

|

50 mm

| | |

| No stock item (MOQ) | 425556 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 23 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

23 mm

| | |

| No stock item (MOQ) | 426526 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1250 (+/-30) x 2000 mm |

2.000 mm

|

1.250 mm

|

15 mm

| | |

| No stock item (MOQ) | 428223 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30,4 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

30,4 mm

| | |

| No stock item (MOQ) | 428251 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30,4 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

30,4 mm

| | |

| No stock item (MOQ) | 449165 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

15 mm

| | |

| No stock item (MOQ) | 449837 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 55 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

55 mm

| | |

| No stock item (MOQ) | 452006 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

15 mm

| | |

| No stock item (MOQ) | 452008 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

20 mm

| | |

| No stock item (MOQ) | 452009 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

30 mm

| | |

| No stock item (MOQ) | 452016 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

20 mm

| | |

| No stock item (MOQ) | 452020 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

30 mm

| | |

| No stock item (MOQ) | 457324 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

12 mm

| | |

| No stock item (MOQ) | 457325 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

40 mm

| | |

| No stock item (MOQ) | 457503 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 12 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

12 mm

| | |

| No stock item (MOQ) | 457511 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

15 mm

| | |

| No stock item (MOQ) | 457513 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

40 mm

| | |

| No stock item (MOQ) | 457921 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 30,2 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

30,2 mm

| | |

| No stock item (MOQ) | 465272 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 43 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

43 mm

| | |

| No stock item (MOQ) | 465396 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 43 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

43 mm

| | |

| No stock item (MOQ) | 465485 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 43 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

43 mm

| | |

| No stock item (MOQ) | 467895 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 23 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

23 mm

| | |

| No stock item (MOQ) | 469252 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 23 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

23 mm

| | |

| No stock item (MOQ) | 470469 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 23 x 1000 x 4000 mm |

4.000 mm

|

1.000 mm

|

23 mm

| | |

| No stock item (MOQ) | 471689 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 81 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

81 mm

| | |

| No stock item (MOQ) | 471724 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 40 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 472224 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 70,3 (-0/+0,6) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

70,3 mm

| | |

| No stock item (MOQ) | 472226 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 80,3 (-0/+0,6) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

80,3 mm

| | |

| No stock item (MOQ) | 472227 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 85,3 (-0/+0,6) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

85,3 mm

| | |

| No stock item (MOQ) | 472228 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 90,3 (-0/+0,6) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

90,3 mm

| | |

| No stock item (MOQ) | 472230 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 100,3 (-0/+0,8) x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

100,3 mm

| | |

| No stock item (MOQ) | 472242 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 71 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

71 mm

| | |

| No stock item (MOQ) | 472246 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 86 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

86 mm

| | |

| No stock item (MOQ) | 472248 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 91 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

91 mm

| | |

| No stock item (MOQ) | 472250 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 101 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

101 mm

| | |

| No stock item (MOQ) | 474349 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 4000 mm |

4.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 474952 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 (+/-0,2) x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 476248 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 15 (+1,5/) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 476251 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 20 (+1,5/) x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 477421 | Polystone® D natural pressed |

sheet

|

sheet

| natural | 45 x 1250 (-0/) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

45 mm

| | |

| No stock item (MOQ) | 217841 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 20 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 276520 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 30 (-0/+0,4) x 1250 (+/-30) x 3000 (-0/+100) mm |

3.000 mm

|

1.250 mm

|

30 mm

| | |

| No stock item (MOQ) | 277405 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 20 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

20 mm

| | |

| No stock item (MOQ) | 277497 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 278418 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 30 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

30 mm

| | |

| No stock item (MOQ) | 281845 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 15 x 2500 x 6000 mm |

6.000 mm

|

2.500 mm

|

15 mm

| | |

| No stock item (MOQ) | 336647 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 12 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

12 mm

| | |

| No stock item (MOQ) | 336650 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 12 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

12 mm

| | |

| No stock item (MOQ) | 405122 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 10 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

10 mm

| | |

| No stock item (MOQ) | 480230 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 24 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

24 mm

| | |

| No stock item (MOQ) | 480323 | Polystone® D UV-stabilized natural pressed |

sheet

|

sheet

| natural | 24 x 2000 x 6000 mm |

6.000 mm

|

2.000 mm

|

24 mm

| | |

| No stock item (MOQ) | 210758 | Polystone® D non-twisting natural pressed |

sheet

|

sheet

| natural | 40 x 1000 x 2500 mm |

2.500 mm

|

1.000 mm

|

40 mm

| | |

| No stock item (MOQ) | 210759 | Polystone® D non-twisting natural pressed |

sheet

|

sheet

| natural | 40 x 1000 x 2200 mm |

2.200 mm

|

1.000 mm

|

40 mm

| | |

| Stock item (no MOQ) | 211810 | Polystone® D non-twisting natural pressed |

sheet

|

sheet

| natural | 15 x 2000 x 3000 mm |

3.000 mm

|

2.000 mm

|

15 mm

| | |

| No stock item (MOQ) | 211904 | Polystone® D non-twisting natural pressed |

sheet

|

sheet

| natural | 40 x 1000 x 2000 mm |

2.000 mm

|

1.000 mm

|

40 mm

| | |