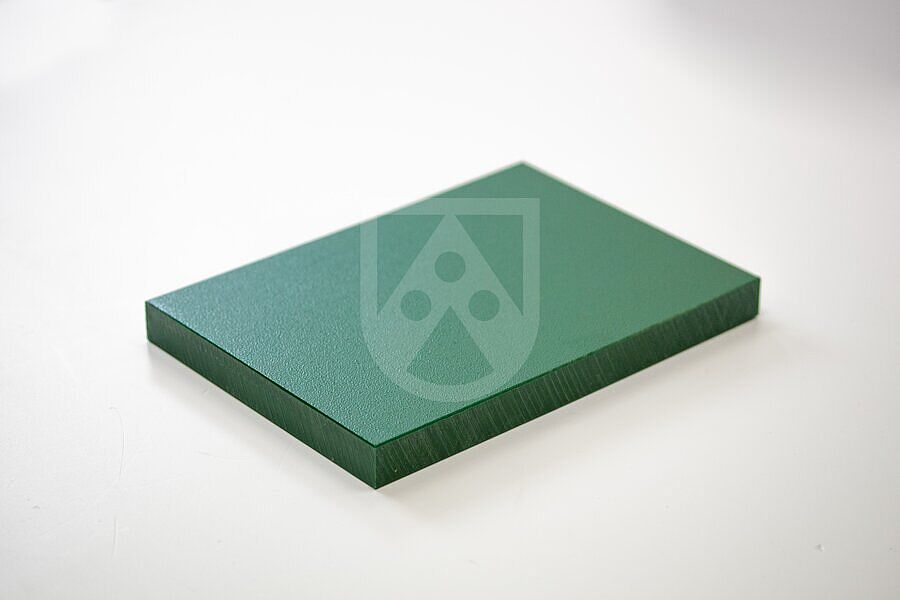

Play-Tec® UV-stabilized green

PE — PE-HD - PE 300

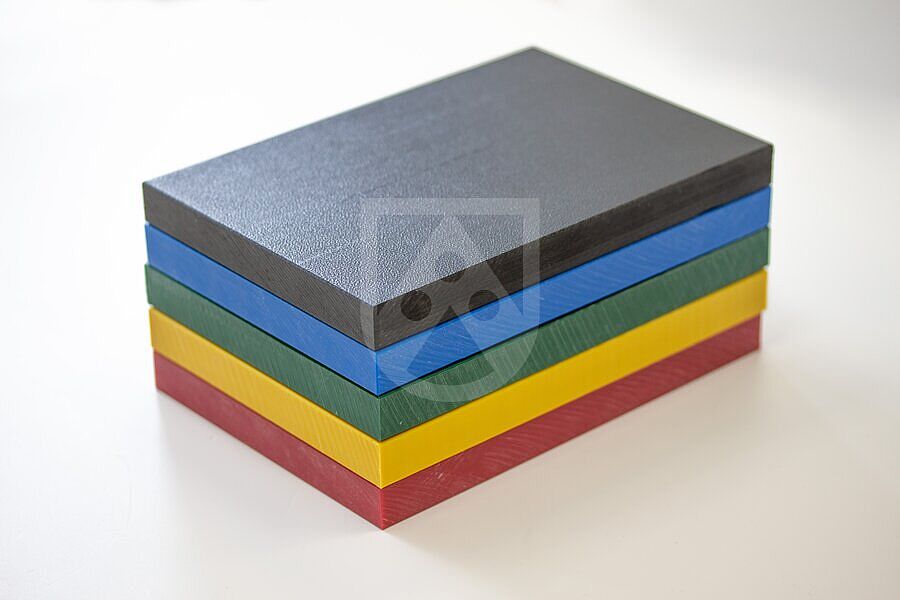

Play areas: safe, long-lasting and colourful with Play-Tec®

I bambini vogliono giocare, saltare e scoprire il mondo. I parchi gioco sono il luogo ideale per lo sviluppo delle abilità motorie e sociali dei bambini, Per i genitori la cosa più importante è che le attrezzature da gioco siano a misura di bambino e sicure. Solo così potranno sentirsi sicuri di lasciar fare nuove esperienze ai loro piccoli. Questi fattori devono essere presi in considerazione nella progettazione e nella costruzione dei parchi giochi. Play-Tec® è stato sviluppato principalmente per la costruzioni di parchi gioco. I materiali soddisfano i requisiti elevati di

- sicurezza

- longevità

- qualità visiva

Characteristics

- Physiologically safe

- UV-stabilized

- Colourfast

- Good machinability

- UV-resistant

Application Examples

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stock item (no MOQ) | 100656 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pine green, similar RAL 6028 | 19 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 19 mm | ||

| Stock item (no MOQ) | 229113 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pine green, similar RAL 6028 | 12,7 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 12,7 mm | ||

| No stock item (MOQ) | 229114 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pine green, similar RAL 6028 | 15 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 15 mm | ||

| No stock item (MOQ) | 333249 | Play-Tec® UV-stabilized green extruded | sheet | sheet | yellow green, similar RAL 6018 | 20 x 1500 x 3000 mm | 3.000 mm | 1.500 mm | 20 mm | ||

| No stock item (MOQ) | 364524 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pantone green 355 C | 18 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 18 mm | ||

| No stock item (MOQ) | 364526 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pantone green 2292 C | 18 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 18 mm | ||

| No stock item (MOQ) | 408726 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pantone green 2292 C | 19 x 1220 x 2440 mm | 2.440 mm | 1.220 mm | 19 mm | ||

| Stock item (no MOQ) | 450273 | Play-Tec® UV-stabilized green extruded | sheet | sheet | pantone green 2292 C | 19 x 1500 x 3000 mm | 3.000 mm | 1.500 mm | 19 mm | ||

| No stock item (MOQ) | 475760 | Play-Tec® UV-stabilized green extruded | sheet | sheet | yellow green, similar RAL 6018 | 19 x 1500 x 3000 mm | 3.000 mm | 1.500 mm | 19 mm | ||

| No stock item (MOQ) | 478745 | Play-Tec® UV-stabilized green extruded | sheet | sheet | yellow green, similar RAL 6018 | 10 x 1500 x 3000 mm | 3.000 mm | 1.500 mm | 10 mm | ||

| No stock item (MOQ) | 478747 | Play-Tec® UV-stabilized green extruded | sheet | sheet | yellow green, similar RAL 6018 | 15 x 1500 x 3000 mm | 3.000 mm | 1.500 mm | 15 mm |

Technical Specifications Play-Tec® UV-stabilized green

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | >0,96 |

| Water absorption | DIN EN ISO 62 | % | 0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Flammability (Thickness 3 - 10 mm) | DIN 4102 | B2 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | >23 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >1100 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | >10 |

| Shore hardness | DIN EN ISO 868 | scale D | >60 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 130 ... 135 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,40 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,90 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 ... 230 |

| Service temperature, long term | Average | °C | -30 … 80 |

| Service temperature, short term (max.) | Average | °C | 100 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 67 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | IEC 60250 | 2,4 | |

| Dielectric dissipation factor (106 Hz) | IEC 60250 | 0,0004 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |

| Comparative tracking index | IEC 60112 | 600 | |

| Dielectric strength | IEC 60243 | kV / mm | >40 |