SustaPEEK CM LD natural

PEEK

Lighter, more efficient, more powerful - your advantage in lightweight construction.

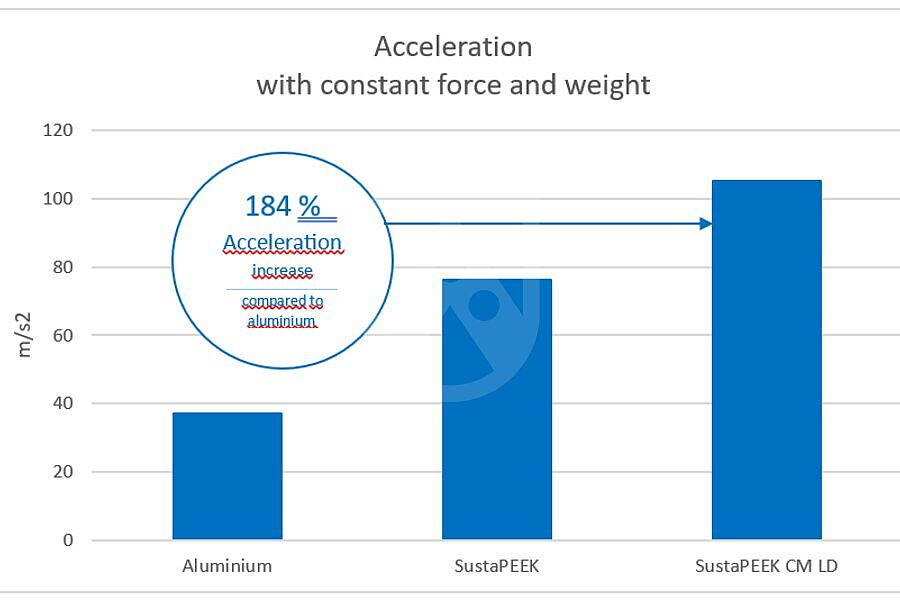

SustaPEEK® CM LD was specially developed for demanding lightweight construction applications. The abbreviation LD stands for Low Density - and that is exactly what makes the difference: less weight (up to 30%) , more efficiency.

Manufactured using a high-quality hot pressing process, SustaPEEK® CM LD impresses with extremely low residual stresses and minimal distortion - for maximum dimensional accuracy and process reliability.

Whether higher loads, faster processes or reduced energy costs - with this high-performance solution you get more out of your process. Rely on intelligent lightweight design and secure your efficiency advantage.

Characteristics

- Low weight

- High dimensional stability

- Good thermal stability

- Good mechanical properties

- Flame retardant

- Chemical resistant

SustaPEEK CM (compression mould) is available with MOQ 1pcs in dimension 395x395mm in various thicknesses.

Daniel Bröder - Product Manager - Business Development, Mail: dbroeder@roechling.com

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 883545 | SustaPEEK CM LD natural pressed | sheet | sheet | natural | 16 x 395 x 395 mm | 395 mm | 395 mm | 16 mm | ||

| No stock item (MOQ) | 904320 | SustaPEEK CM LD natural pressed | sheet | sheet | natural | 12 x 395 x 395 mm | 395 mm | 395 mm | 12 mm |

Technical Specifications SustaPEEK CM LD natural

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,95 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Elongation at break | DIN EN ISO 527 | % | 2 |

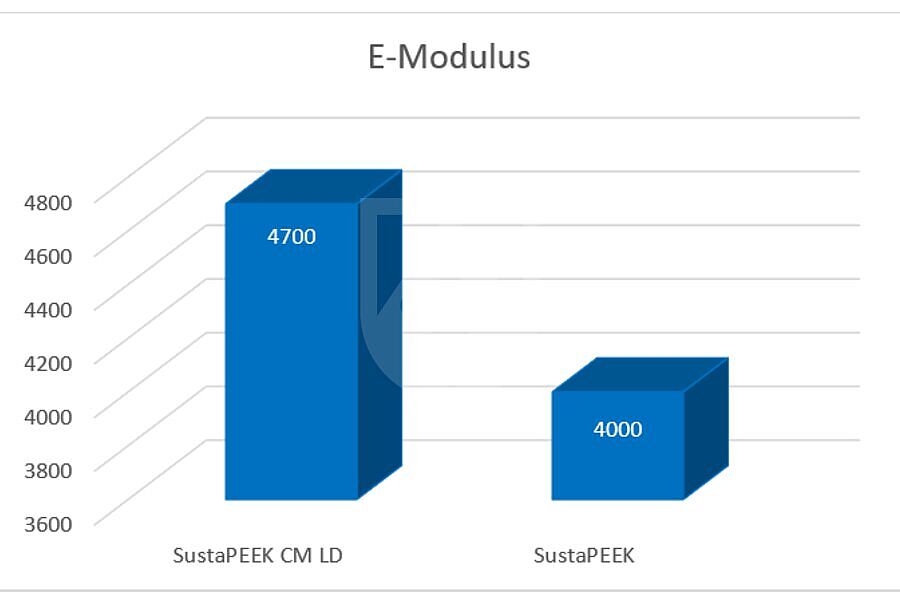

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 4700 |

| Tensile strength | DIN EN ISO 527 | MPa | 65 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | 2 |

| Shore hardness | DIN EN ISO 868 | scale D | 85 |

| Ball indentation hardness | DIN EN ISO 2039-1 | MPa | 250 |

| Elastic modulus of compression | DIN EN ISO 604 | MPa | 4000 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 337 |

| Service temperature, long term | Average | °C | -60...250 |

| Service temperature, short term (max.) | Average | °C | 310 |