Materials and parts for Surgery

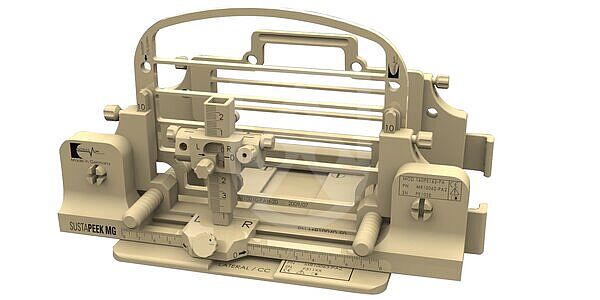

For operations on or in a patient’s body various instruments and devices are required. We offer a wide range of materials and parts for this demanding medical field. We machine surgical instruments such as handles, surgical cutlery or camera housings as well as trial implants in many clearly visible colours. Beside this our high-performance materials are also used in minimally invasive surgery - for example as an eyepiece funnel, endoscopy, guides or sliding elements.

Typical parts include

- Handles

- Cutlery

- Housings

- Implant sizing trials

- Funnels

- Guides

- Sliding elements

Application examples

The performance and service life of materials used in the healthcare sector are influenced by a variety of factors. When choosing the right material, factors such as surface quality requirements, contact with cleaning agents, disinfectants, dimensions and/or tolerances are essential.

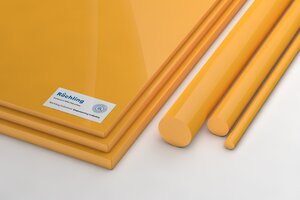

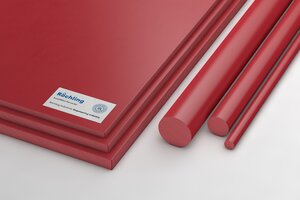

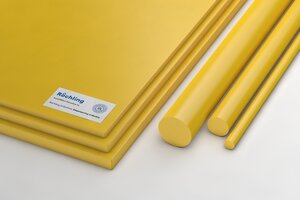

Selection of Medical Grade Products

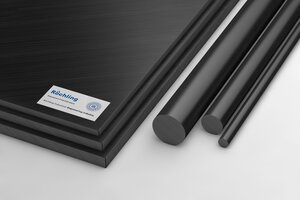

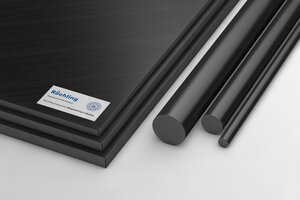

- PEEK

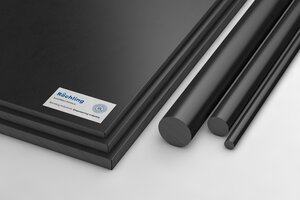

SustaPEEK MG black

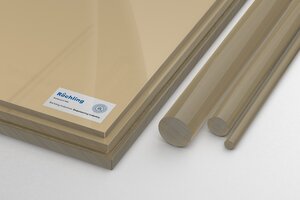

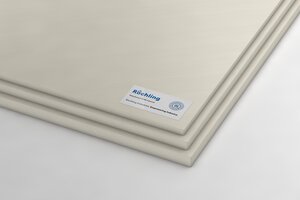

- PEEK

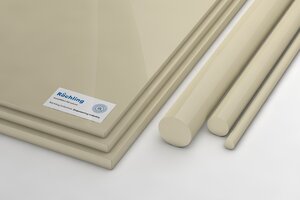

SustaPEEK MG natural

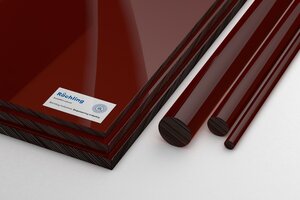

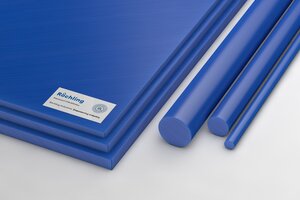

- PEEK

SustaPEEK MG blue BL

- PEEK

SustaPEEK MG red RD

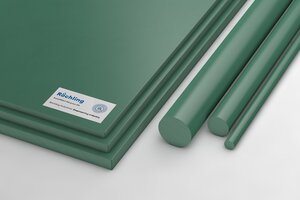

Selection of Healthcare Grade products

- PE > PE-HD - PE 300

Polystone® G HG white

- PVDF

SustaPVDF HG natural