Optimizing a Complex Assembly for a Class 3 Medical Device

For the production of a class 3 medical device used in an operating theatre, our customer needed support for converting the preliminary model into an optimized new model.

The product optimizing project for the complex assembly involved reengineering it entirely while simplifying and safeguarding the whole-system functionality.

The Challenge:

- Product optimizing and redesign of a complex assembly consisting of 29 components with different properties and materials

- No restriction of the functionality and handling of the end product

Smart Re-Design for a Simplified Manufacturing Process and Automated Assembly

Using the know-how of our development department, we revised the entire assembly in close consultation with the customer.

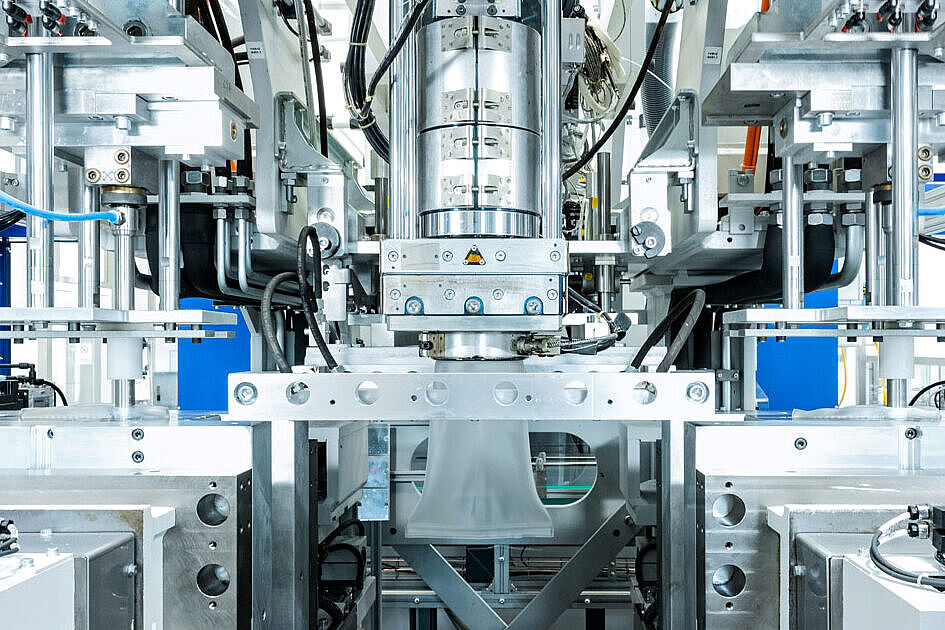

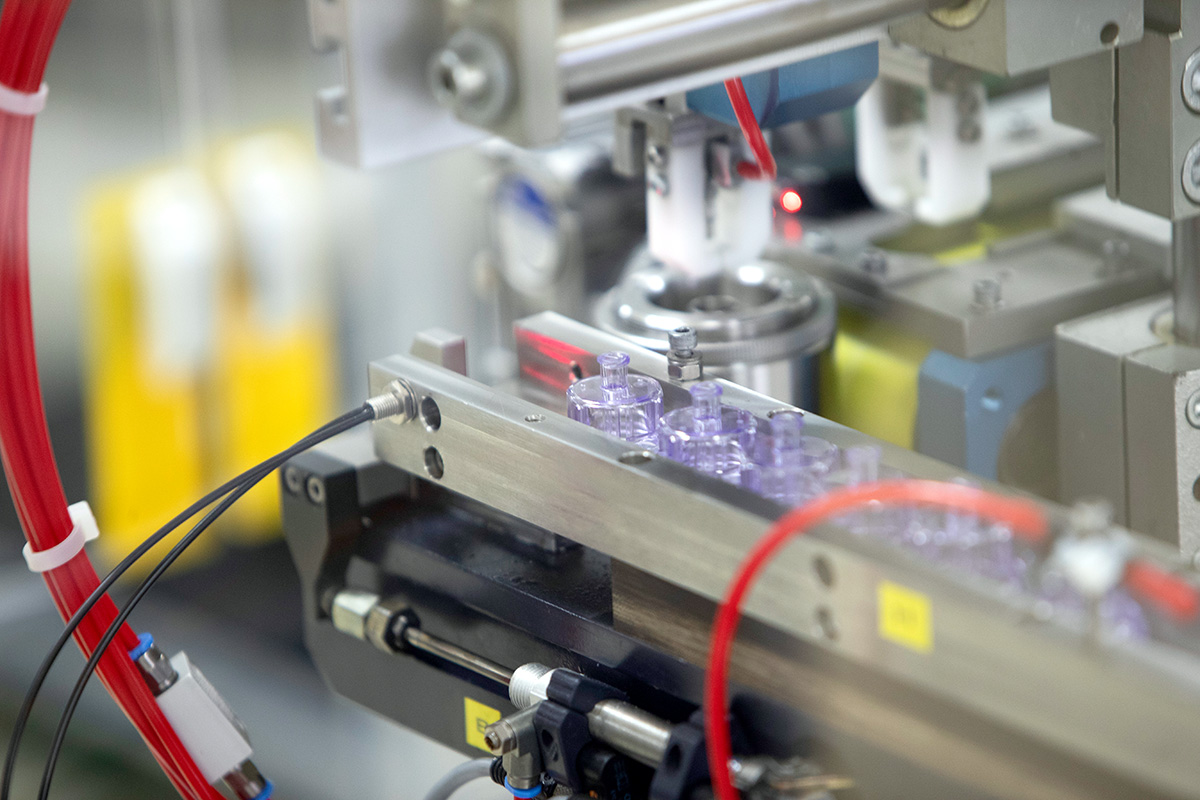

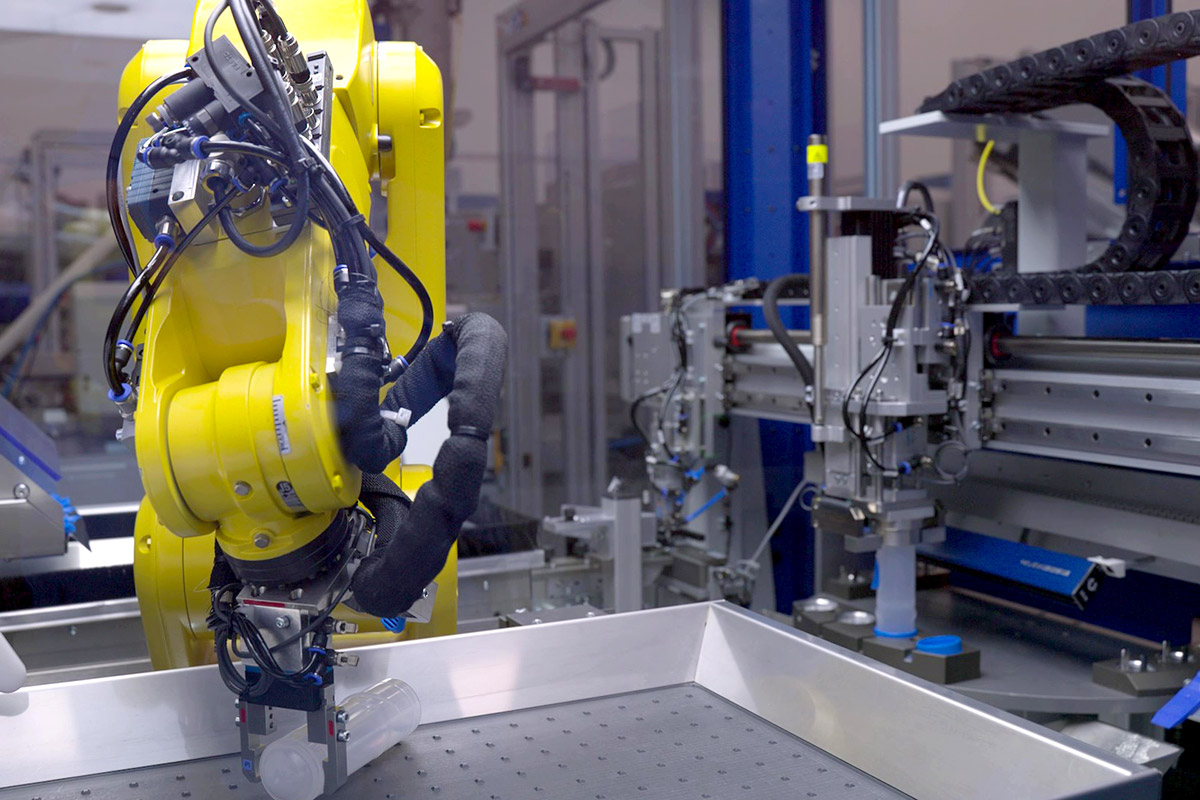

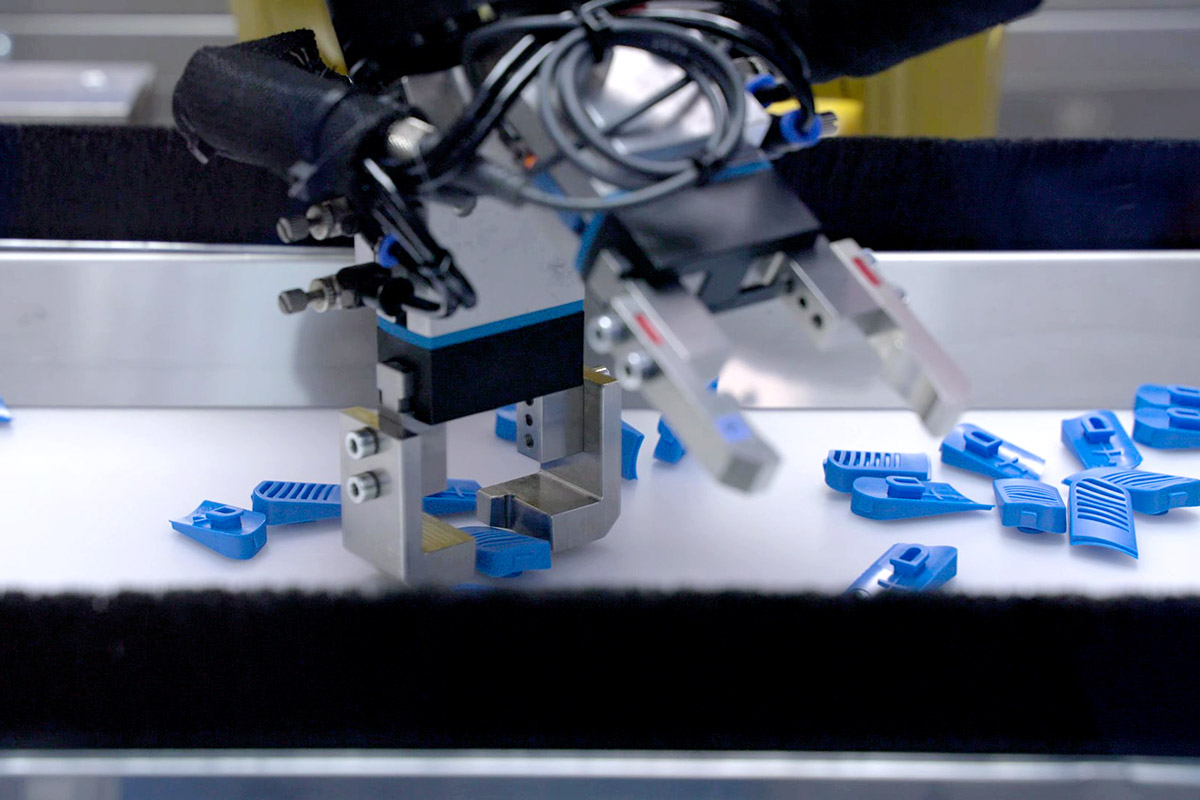

In order to simplify the existing complex manufacturing and assembly steps and to minimize the purchase of external parts, all individual parts were checked for practicality and manufacturing complexity. The development of precision-fit injection molded parts made it possible to implement automated assembly. In addition to simplifying assembly, this led to a significant cost reduction. At the same time, the number of parts required was reduced and the supply chain was simplified. Intelligent product development and mold design ensured optimizing of the product's functionality and guaranteed plastic-compatible and process-safe production.

Key Expertise:

- Product smartly redesigned for automated assembly

- Previously bought in functional parts redesigned for injection molding, thereby reducing costs

Improved Device With Higher Production Efficiency and Lower Cost

Overall, the technical expertise of our development department in creating intelligent concepts to improve process parameters and generate process stability guaranteed the project's successful implementation. Intelligent redesign also made it possible to integrate additional functions into the device that previously required an add-on device.

Advantages for Our Customer:

- Time and cost savings due to material savings

- Reduction of the total number of parts, thus less dependence on external suppliers

- Optimizing and shortening of assembly processes and increased process stability

- Intelligent product development and component layout in order to optimize the product's design, ergonomics and functionality, and enable plastic-compatible and process-safe production

- In-house handling of the entire process from re-design to series production readiness.

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical device and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for medical applications and customized design options, please contact our team.

We look forward to hearing from you.

Your Contact

Thierry Arnaud

Vice President - Sales & Marketing Europe