Engineering Competence for Superior Results

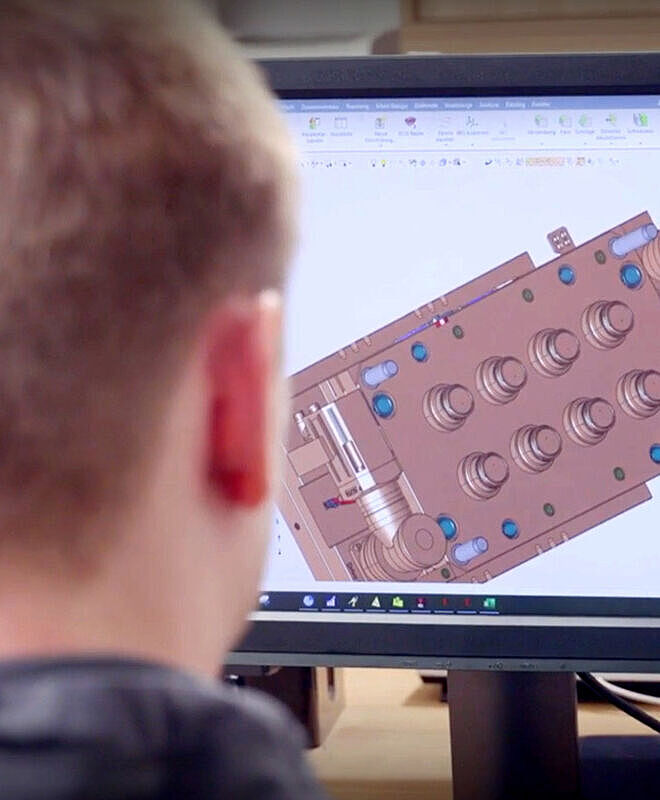

Our strong in-house engineering allows us to control the process every step of the way. Röchling Medical provides engineering support from design for manufacturing all the way through series production. Whether for product realization, process design and development, product line transfers or complete contract manufacturing solutions, Röchling Medical engineers bring fresh insights and innovative solutions to any project.

Customized Automation Solutions

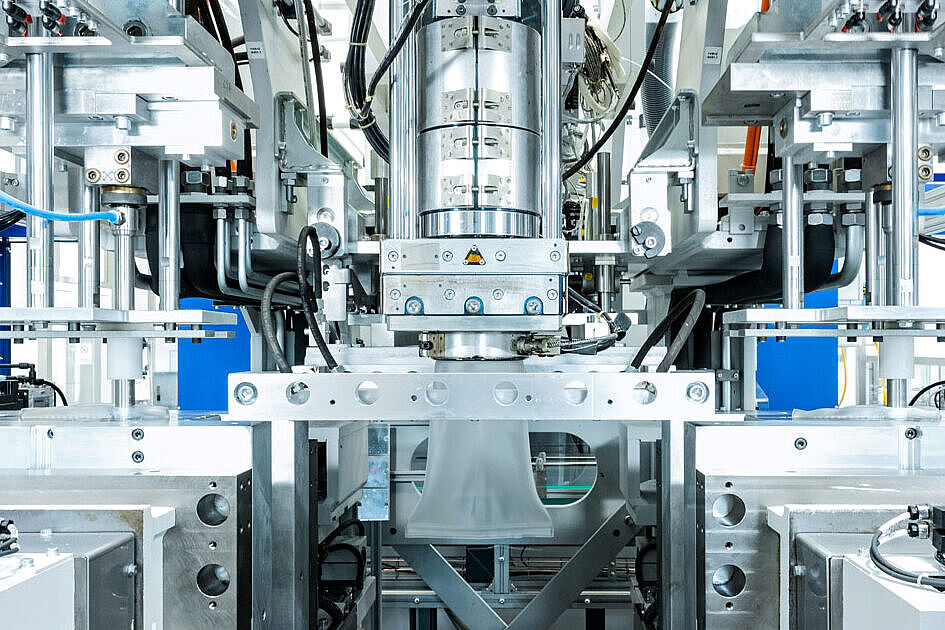

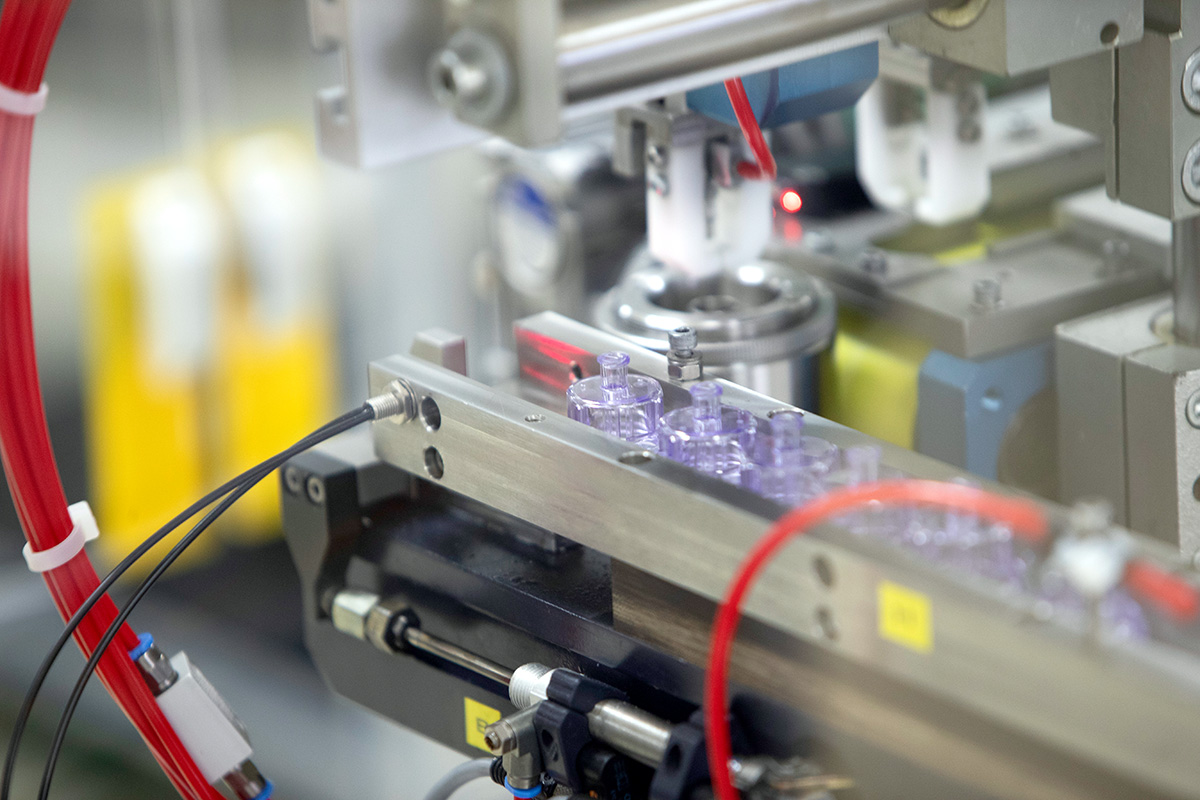

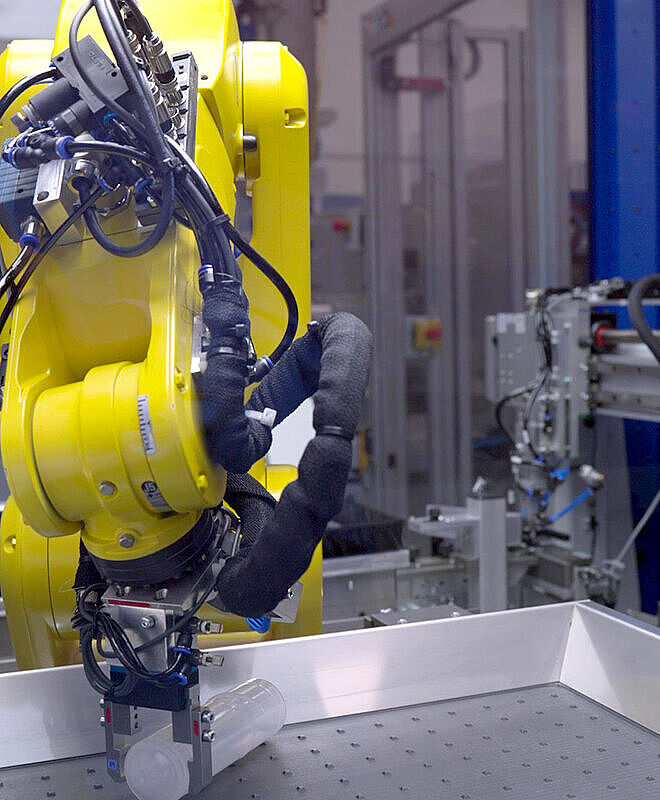

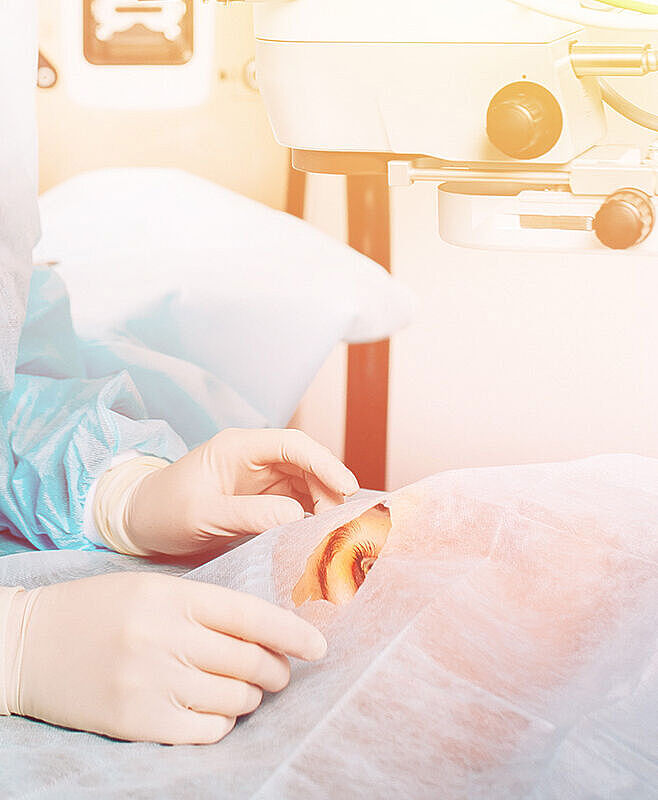

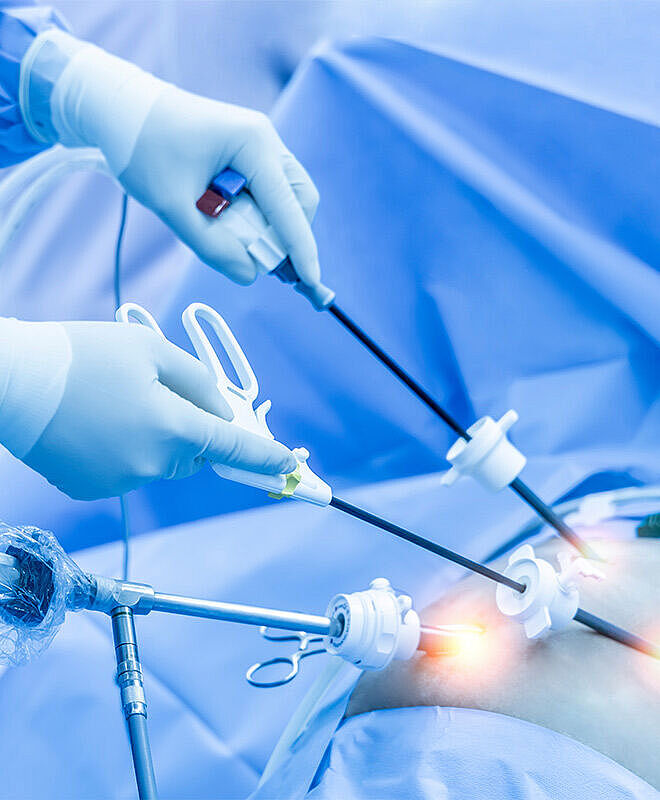

We use our knowledge in automation to create smart solutions and lean processes using innovative technologies.

Our in-house automation engineering department develops product-specific processes from manual precision to fully automated production, using automatic assembly, automatic inline quality testing, robot-assisted parts insertion and removal, as well as automatic packaging and transportation systems.

We are able to plan, control and implement complex automatic systems for large series production in cleanrooms in compliance with ISO 14644-1:2016 class 7 / 8 or GMP Grade C / D. Depending on project requirements, the design, construction and programming are carried out by Röchling Medical or in collaboration with external partners.

Experienced Project Management

Our experienced project managers advise and support customers from the initial idea through to series production.

Röchling Medical is experienced in managing highly complex projects from initial clean room layout and process design to ramp-up. We place great emphasis on a holistic approach and transparent project planning for optimal implementation of schedules and budgets.

In close consultation with our customers, our experts develop processes that fulfill the requirements for stable, reliable production and highest quality while being economically efficient.

Competences at the Following Locations

Case Studies

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

Patient-Centric Pharmaceutical Packaging Design

Optimizing a Complex Class 3 Medical Device

Innovative Plastic Protectors for Glass Injection Vials

Custom Automation Concepts

Design for Manufacturability

Automated Quality Control

Metal and Plastic Processing from a Single Source

Medical Device Contract Manufacturing

A Single Use Medical Device Designed for Sustainability

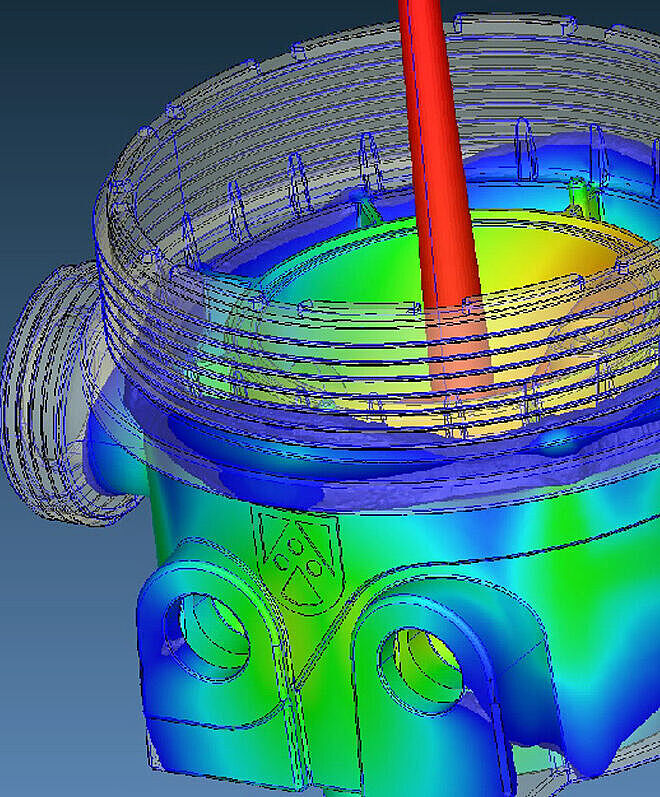

Simulations in Product Development

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our Expertise in Automation and Engineering, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing