Competence in Plastics & Metal Processing

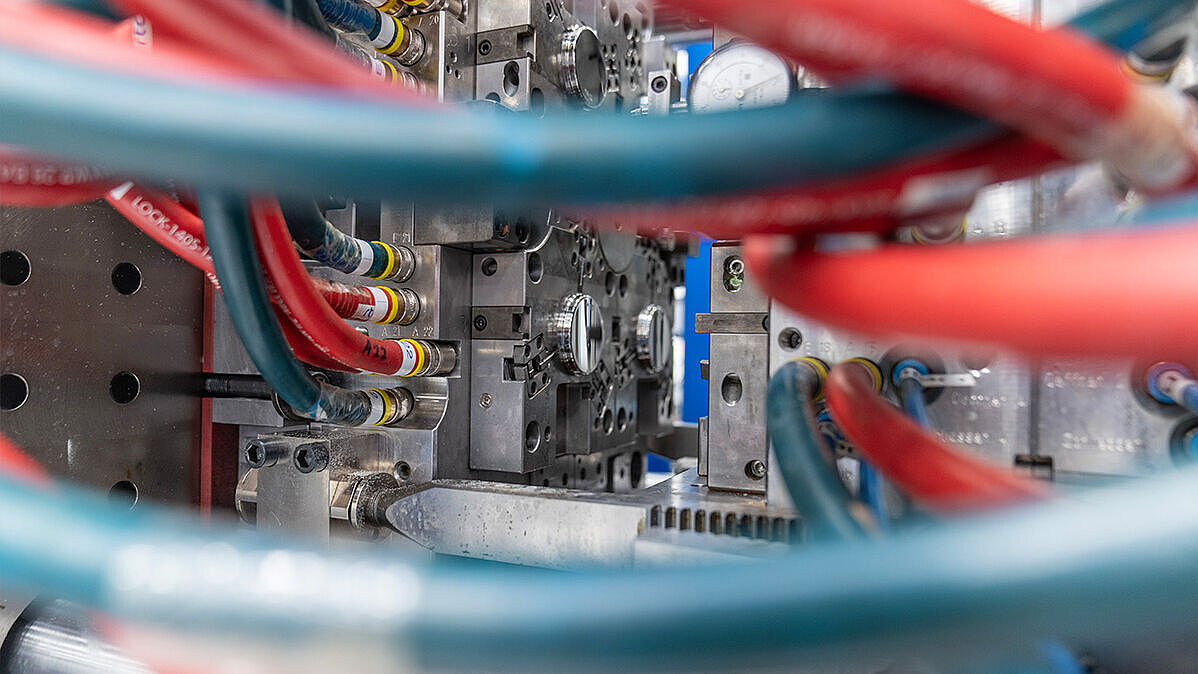

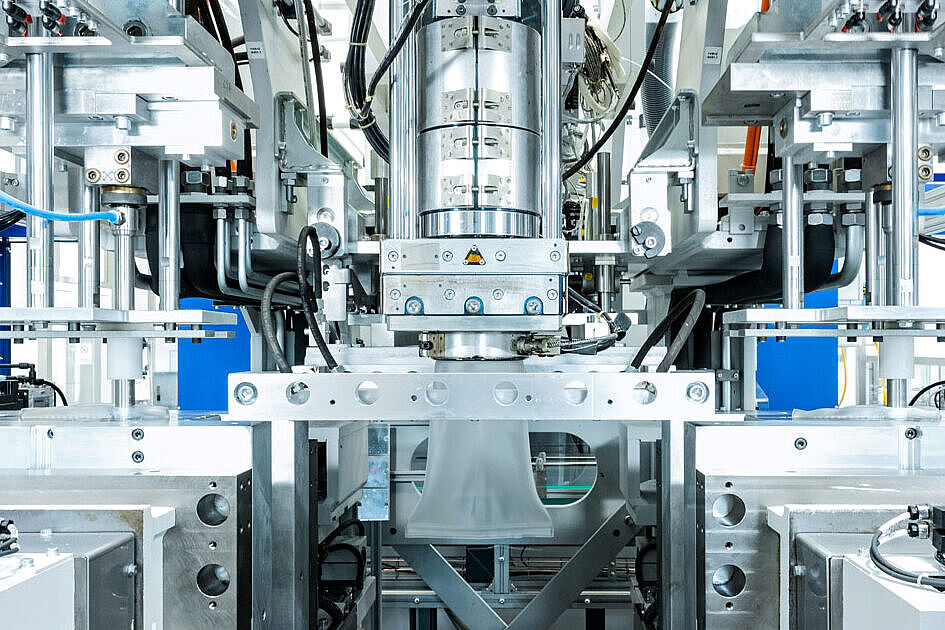

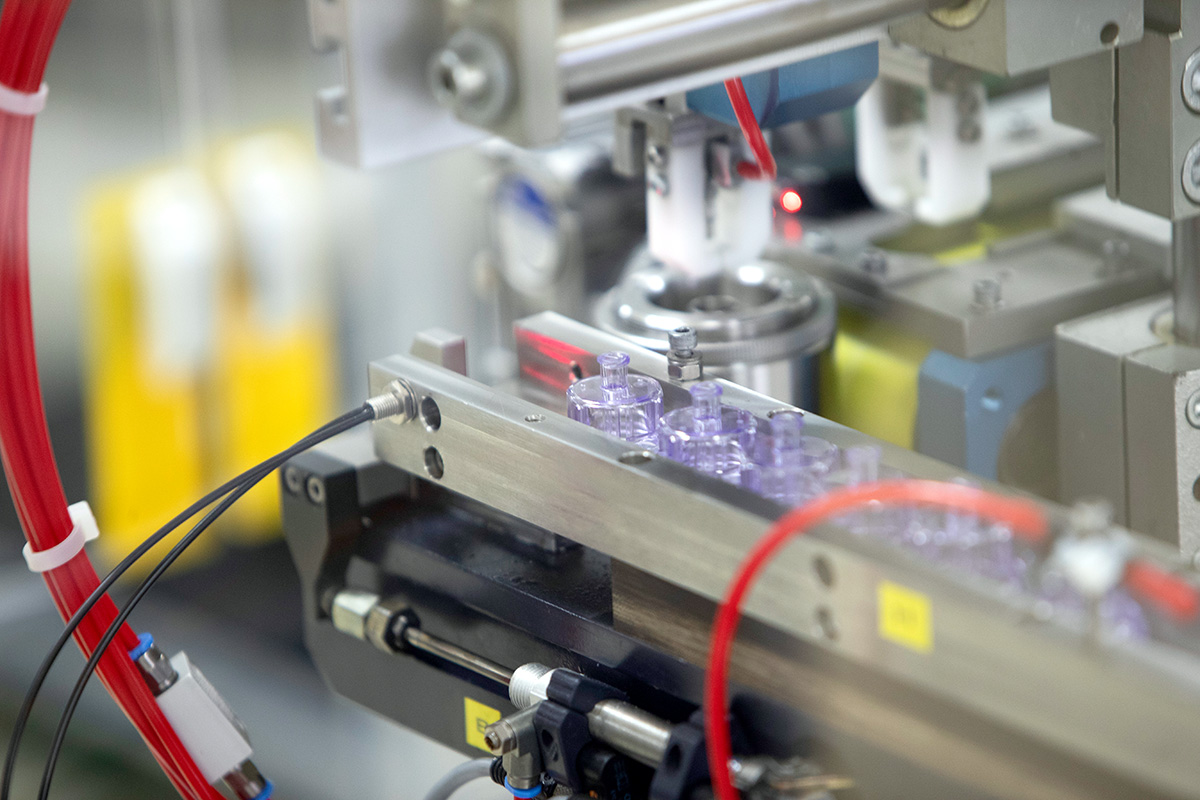

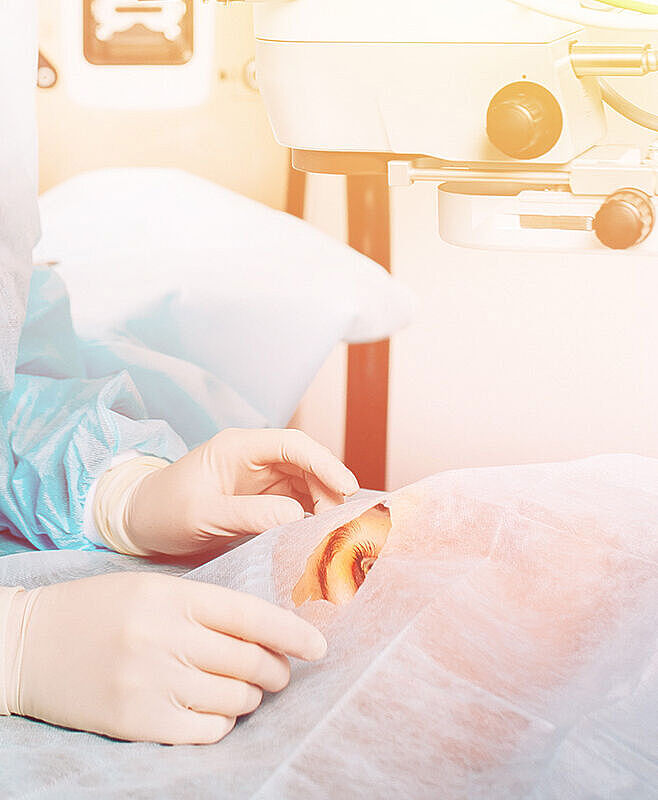

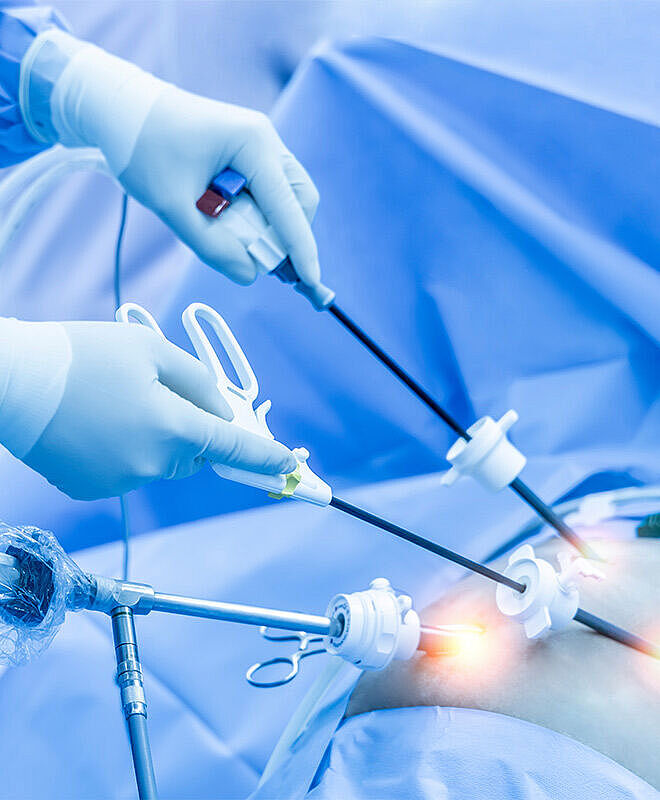

As an experienced specialist in cleanroom manufacturing, we produce custom components and assemblies up to complete OEM products under controlled conditions. With our unique range of thermoplastic and metal processing methods and our expertise in intelligent material selection, we are able to realize the smallest dimensions, tightest tolerances and highest functional requirements for your product.

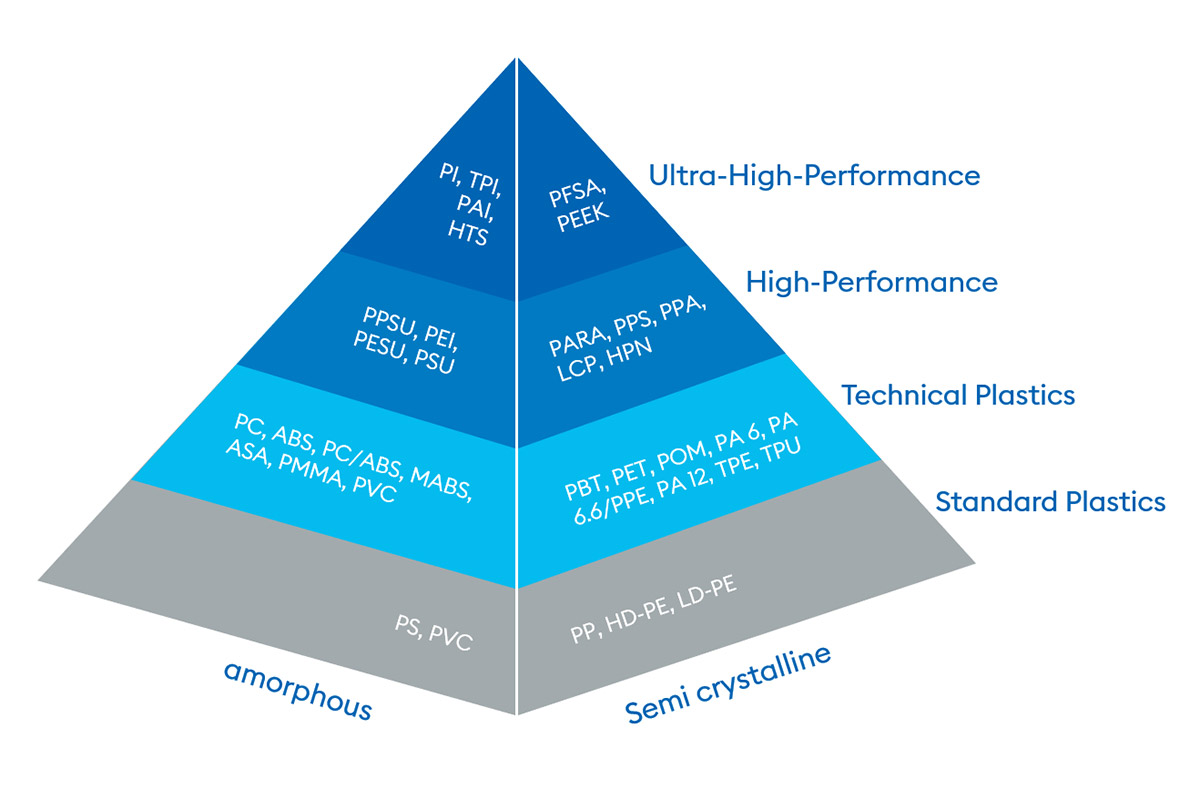

The Right Material From Standard to High Performance

Our experts know the high demands placed on materials in the medical and pharmaceutical sectors and support you in the application-oriented selection of materials for your product.

With decades of experience in processing thermoplastics and a deep understanding of their specific properties, we procure the materials that best meet the individual requirements of your product. In addition to standard and engineering plastics, we are familiar with a wide range of highly heat-resistant plastics, glass-fiber reinforced plastics and thermoplastic elastomers. We are also able to offer renewable polymer alternatives to manufacture more sustainable products.

At our US sites, our material expertise in medical applications is enhanced by know-how in the selection and processing of titanium and metal alloys such as 300 and 400 series stainless steel.

Flexibility Through Technological Variety

We rely on lean processes, innovative technologies and a consistent focus on your requirements when it comes to solutions for medical technology, pharma and diagnostics.

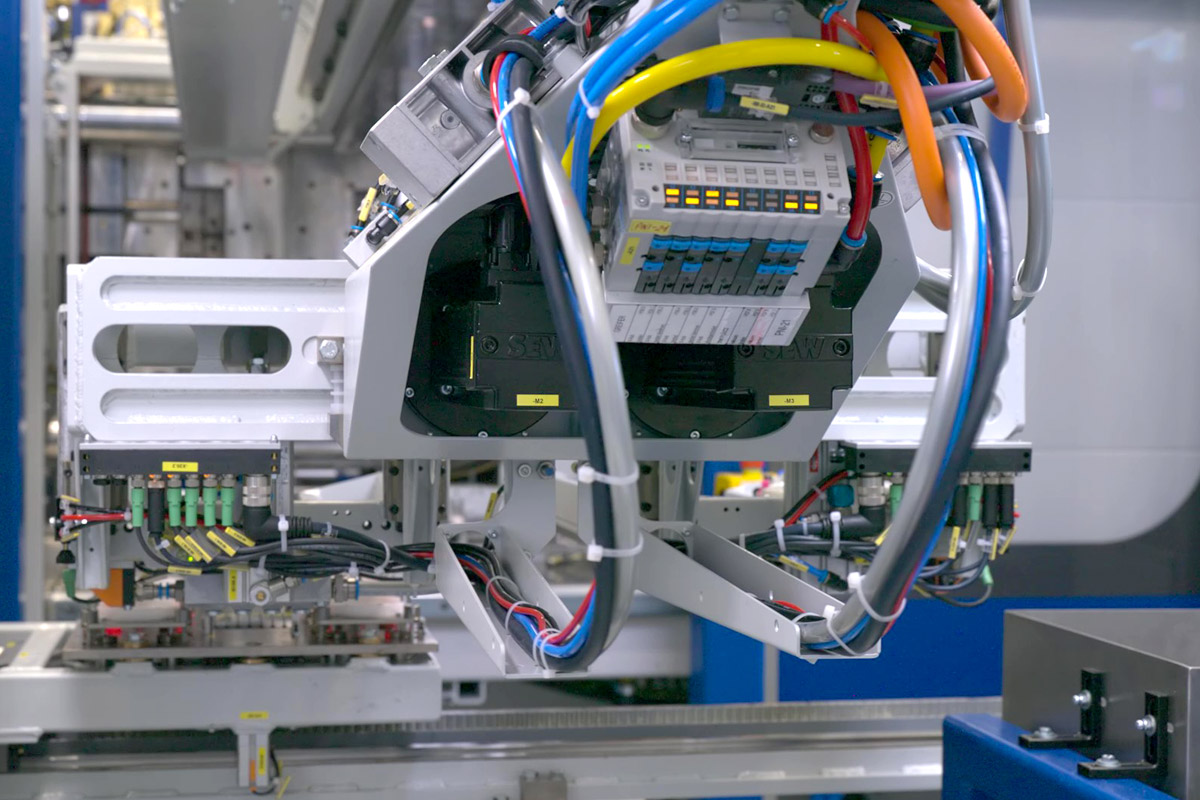

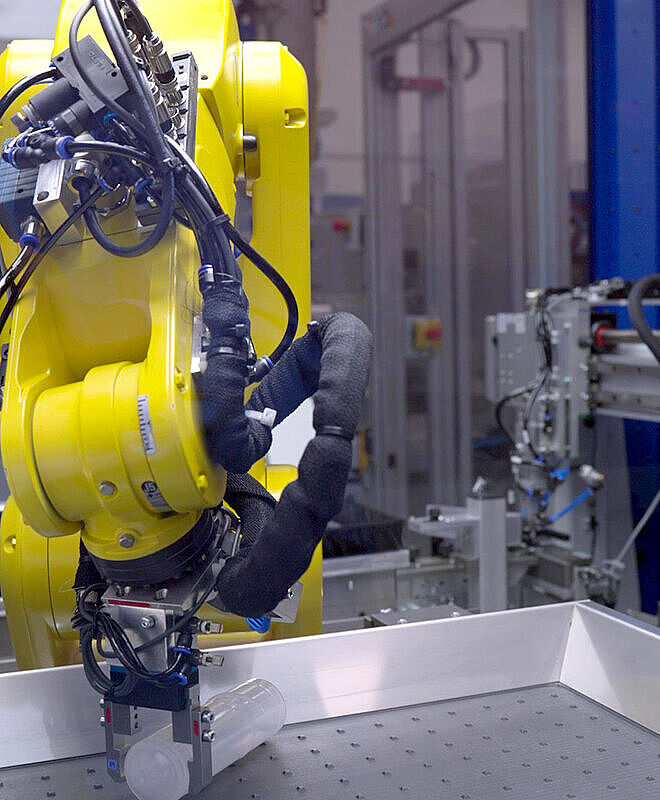

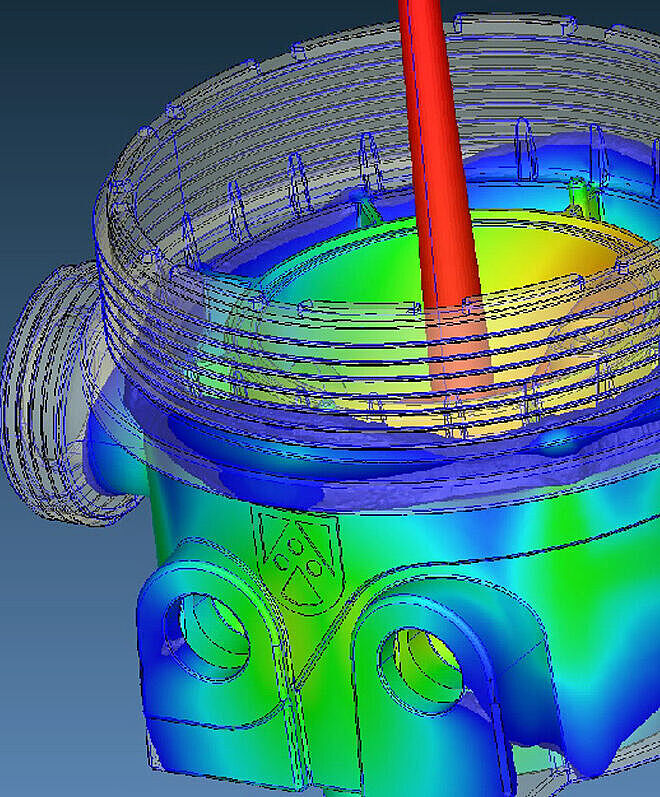

At our global locations, we cover a wide range of manufacturing technologies, enabling us to find a suitable, customized solution for individual requirements. Our European sites are experts in plastics processing and offer a unique range of thermoplastic processing technologies in the cleanroom. This is complemented by individual automation concepts and downstream processes to realize your products quickly, economically and in compliance with your quality requirements. In addition, we have a high level of expertise in metal processing at our US sites.

Get To Know Our Competence Centers

Case Studies

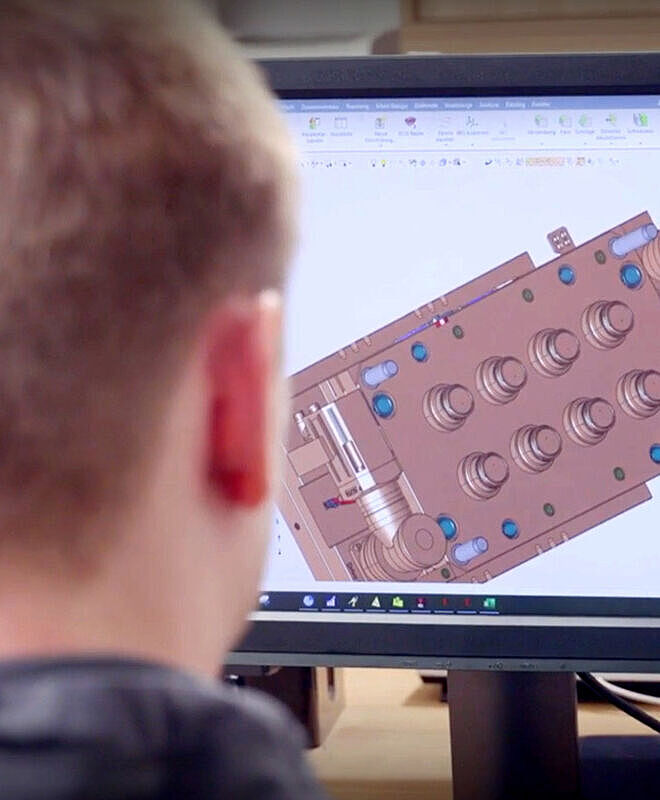

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

Patient-Centric Pharmaceutical Packaging Design

Optimizing a Complex Class 3 Medical Device

Innovative Plastic Protectors for Glass Injection Vials

Custom Automation Concepts

Design for Manufacturability

Automated Quality Control

Metal and Plastic Processing from a Single Source

Medical Device Contract Manufacturing

A Single Use Medical Device Designed for Sustainability

Simulations in Product Development

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our competence in medical plastic and metal processing, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing