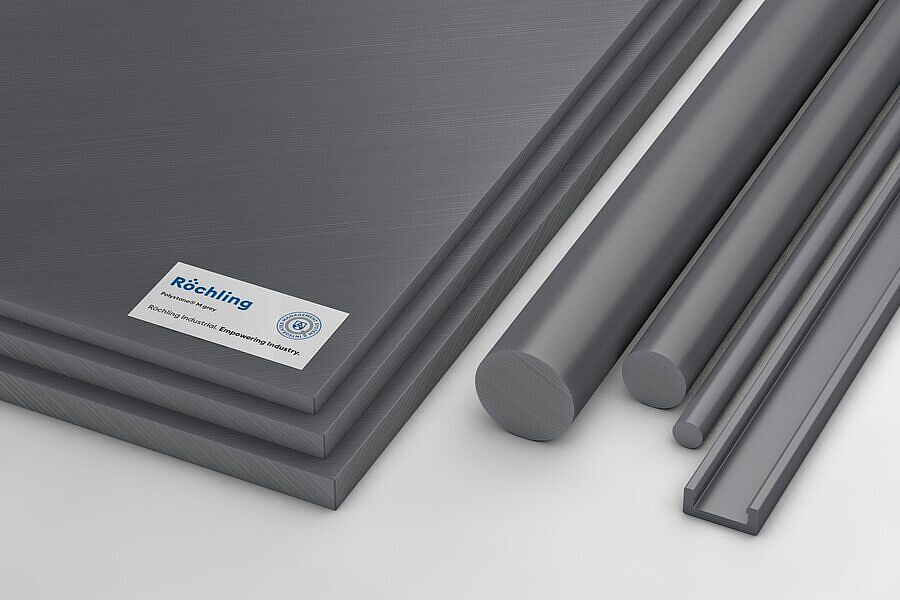

Polystone® M Grey - ASTM

PE — PE-UHMW - PE 1000

Characteristics

- Low coefficient of friction

- Good wear properties

- Good impact strength

Industries

- Food Industry

Technical Specifications Polystone® M Grey - ASTM

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | ASTM D792 | g / cm3 | 0.93 |

| Water Absorption | ASTM D570 | % | 0.10 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Wear resistance | Sand-slurry | 100 | |

| Hardness | ASTM D2240 | Shore D | 62 - 66 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 3100 |

| Tensile Modulus | ASTM D638 | psi | 100000 |

| Elongation at Break | ASTM D638 | % | >350 |

| Flexural Strength | ASTM D790 | psi | 3500 |

| Compressive Strength | ASTM D695 | psi | 3000 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | No Break |

| Coefficient of Friction, Dynamic | 0.10-0.22 | ||

| Coefficient of Friction, Static | 0.15-0.20 | ||

| Izod Impact Strength | ASTM D4020 | kJ / m2 | 125 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| CTE, linear | ASTM D696 | in/in/°F | 1.1x10-4 |

| Melting Point | ASTM D3418 | °F | 266 - 275 |

| Vicat Softening Point | ISO306 | °F | 176 |

| Maximum Service Temperature, Air | °F | 180 | |

| Heat Deflection Temperature 264psi | ASTM D648 | °F | 108 |

| Flammability, UL94 | 1/8 inch | HB |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume Resistivity | ASTM D257 | Ωcm | >1015 |

| Dielectric constant | ASTM D150 | 1MHz | 2.3 |

| Dielectric strength | ASTM D149 | kV / mm | 45 |

| Surface resistivity | ASTM D257 | Ω/cm | >1012 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| FDA | Yes | ||

| NSF | No | ||

| USDA | Yes |