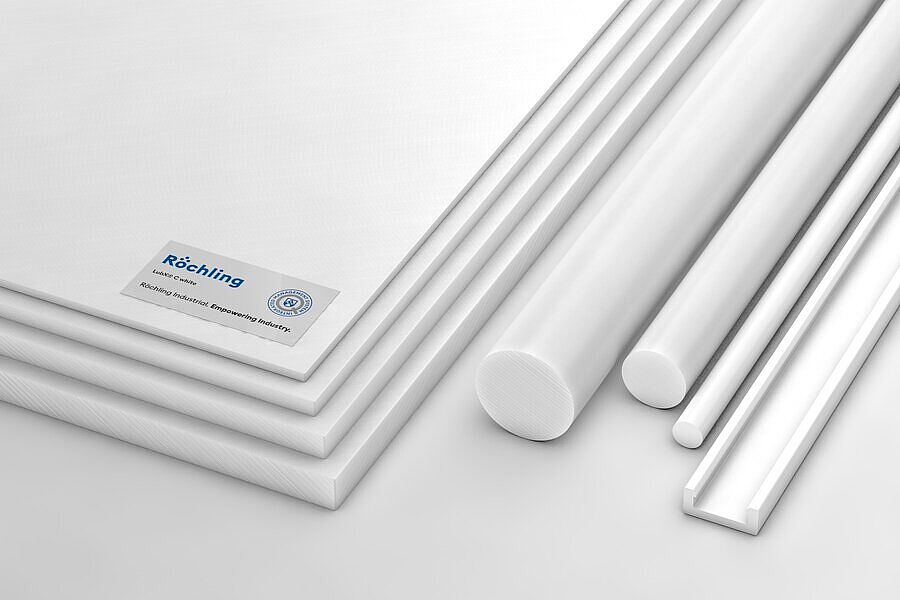

LubX® C white

PE — PE-UHMW - PE 1000

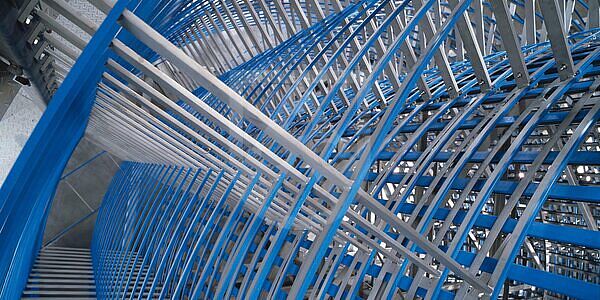

With LubX® C we offer a high performance material especially aligned to POM and steel, which has outstanding dry-running properties at its disposal. They have been especially developed for applications in materials-handling and automation technologies.

- Compared with conventional sliding materials, conveying systems equipped with LubX® C need considerably less energy.

- The considerably lower coefficient of friction of LubX® C eliminates the possibility of the slip-stick effect (backsliding) almost completely and thus increases process stability.

Characteristics

- Energy-saving

- Especially aligned to POM and Steel

- Noise-reducing

- Coefficient of friction with POM as sliding partner up to 75% less than of PE-UHMW

- Coefficient of friction with steel as sliding partner up to 60% less than of PE-UHMW

- Food compliant according to 10/2011/EU, 1935/2004/EC, FDA

Industries

- Food Industry

- Meat, Fish and Poultry Processing

- Bakery and Confectionery

- Beverage Industry

Application Examples

Variants

Technical Specifications LubX® C white

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,93 |

| Water absorption | DIN EN ISO 62 | % | 0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Non-toxicity | + | ||

| Moulding Compound PE | DIN ISO 1872-1 | UHMW-PE-QCD 35-3-4 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | 19 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >500 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | no break |

| Shore hardness | DIN EN ISO 868 | scale D | 60 |

| Sliding partner POM MOD A (0,25 m/s - 0,25 MPa) | REP - Tribology - Test | 0,08 | |

| Sliding partner POM MOD B (0,25 m/s - 0,25 MPa) | REP - Tribology - Test | 0,11 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 133 – 135 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 - 230 (*) |

| Service temperature, long term | Average | °C | -150 … 80 (*) |

| Service temperature, short term (max.) | Average | °C | 130 (*) |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1015 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |