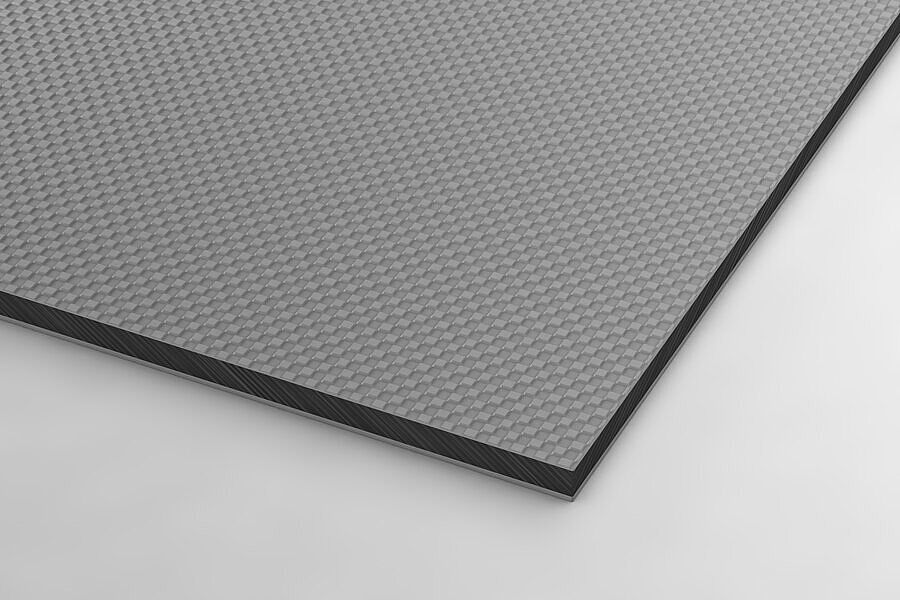

Polystone® Safe-Tec L

PE — PE-HD - PE 300

Characteristics

- Good weather resistance

- Anti-slip property even at wet surface

- Easy processing

- Surface and cut surfaces can be welded together

- No emission of solvents, plasticizers or stabilisers

- Good noise absorption properties

- Vibration damping

Application Examples

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 344862 | Polystone® Safe-Tec L UV-stabilized bicolor extruded | sheet | sheet | bicolor grey/white | 19 x 1220 x 2000 mm | 2,000 mm | 1,220 mm | 19 mm | ||

| No stock item (MOQ) | 344863 | Polystone® Safe-Tec L UV-stabilized bicolor extruded | sheet | sheet | bicolor light brown/brown | 19 x 1220 x 2000 mm | 2,000 mm | 1,220 mm | 19 mm |

Technical Specifications Polystone® Safe-Tec L

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | >0,95 |

| Water absorption | DIN EN ISO 62 | % | 0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Flammability (Thickness 3 - 10 mm) | DIN 4102 | B2 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | >22 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >1000 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | >10 |

| Shore hardness | DIN EN ISO 868 | scale D | >60 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 130 ... 135 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,40 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,90 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 ... 230 |

| Service temperature, long term | Average | °C | -50 … 100 |

| Service temperature, short term (max.) | Average | °C | 100 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 67 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | IEC 60250 | 2,4 | |

| Dielectric dissipation factor (106 Hz) | IEC 60250 | 0,0004 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |

| Comparative tracking index | IEC 60112 | 600 | |

| Dielectric strength | IEC 60243 | kV / mm | >40 |