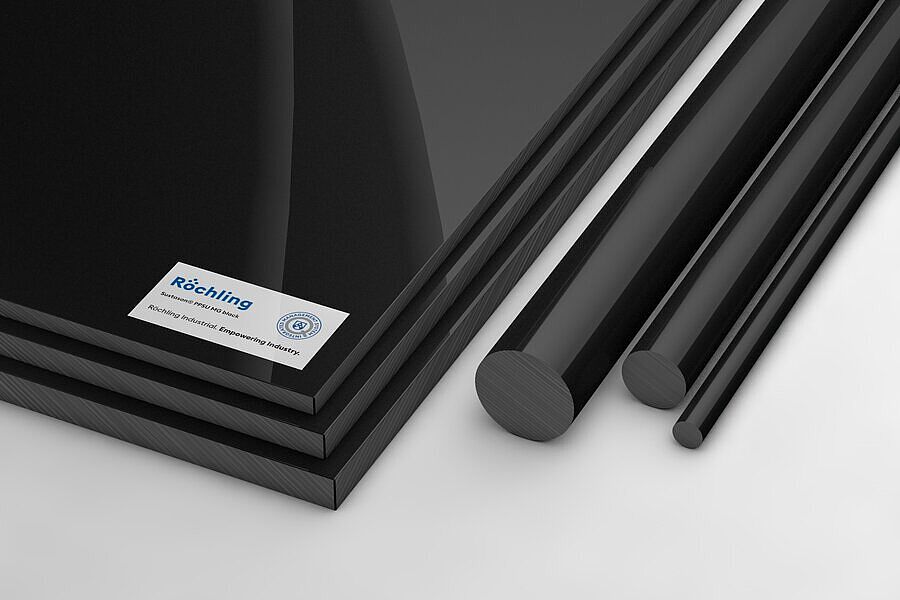

Sustason® PPSU MG (Radel® R5500) black - ASTM

PPSU

Our premium material especially for medical devices

Sustason® PPSU MG (Radel® R5500) was specially developed for demanding applications in the healthcare industry. It offers incredible toughness in applications that receive repeated sterilization. With a high heat deflection temperature of 420° F it can absorb tremendous impact without cracking or breaking.

About:

- 12 standard colors available

- Directly compounded by Syensqo

- Custom colors & BaSO4 available

- Produced in our ISO 13485 Certified facility

- 100% Lot Ultra-Sonic tested in house

- The resin has been tested to over 1000 steam sterilization cycles

- ISO 10993-5 Cytotoxicity done on all colors of extruded rod

Characteristics

- Good sterilisation resistance

- High heat deflection temperature

- ISO 10993-5 tested on semi-finished product

- High impact resistance

- Chemical resistant

- High resistance to gamma and x-rays

Industries

- Surgery

Application Examples

Technical Specifications Sustason® PPSU MG (Radel® R5500) black - ASTM

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | ASTM D792 | g / cm3 | 1.29 |

| Water Absorption 24 hours | ASTM D570 | % | 0.37 |

| Water Absorption Saturation | ASTM D570 | % | 1.1 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hardness | ASTM D2240 | Shore D | 80 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 11000 |

| Tensile Modulus | ASTM D638 | psi | 390000 |

| Elongation at Break | ASTM D638 | % | 30 |

| Flexural Strength | ASTM D790 | psi | 15500 |

| Flexural Modulus | ASTM D790 | psi | 350000 |

| Compressive Strength | ASTM D695 | psi | 14000 |

| Rockwell Hardness | ASTM D785 | M | 80 |

| Rockwell Hardness | ASTM D785 | R | 120 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | 13 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Thermal Conductivity | in/hr/ft2 /°F | 2.42 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | in/in/°F x10-5 | 3.1 |

| Melting Point | ASTM D789 | °F | 424 |

| Continuous Service Temperature, Air | °F | 320 | |

| Deflection Temperature at 1.8Mpa (264psi) | ASTM D648 | °F | 420 |

| Deflection Temperature at 1.8Mpa (66psi) | ASTM D648 | °F | 417 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Surface resistivity | ASTM D257 | Ω/cm | 1016 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| FDA | Yes | ||

| NSF | No | ||

| USDA | Yes |