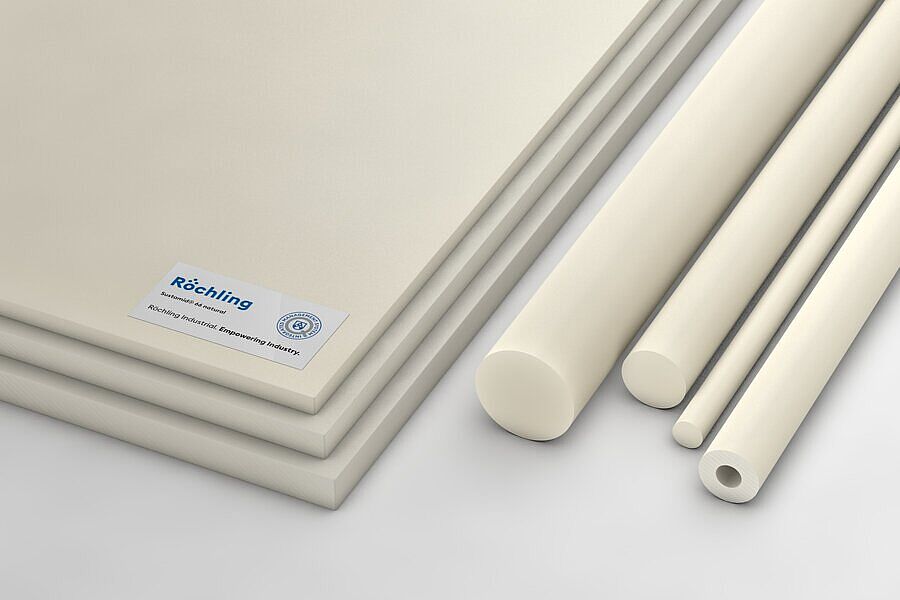

Sustamid® 66 natural - ASTM

PA — PA 66

Characteristics

- Good dimensional stability

- Good sliding properties

- High abrasion resistance

Industries

- Food Industry

Application Examples

Technical Specifications Sustamid® 66 natural - ASTM

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB / V2 | |

| Density | ASTM D792 | g / cm3 | 1.14 |

| Water Absorption 24 hours | ASTM D570 | % | 1 |

| Dissipation Factor | ASTM D150 | 1MHz | 0.02 |

| Water Absorption Saturation | ASTM D570 | % | 8.5 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hardness | ASTM D785 | Shore D | 80 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 12000 |

| Tensile Modulus | ASTM D638 | psi | 400000 |

| Elongation at Break | ASTM D638 | % | 40 |

| Flexural Strength | ASTM D790 | psi | 15000 |

| Flexural Modulus | ASTM D790 | psi | 420000 |

| Compressive Strength | ASTM D695 | psi | 12500 |

| Rockwell Hardness | ASTM D785 | 85 | |

| Rockwell Hardness | ASTM D785 | R | 121 |

| Shear Strength | ASTM D732 | psi | 10000 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | 0.6 |

| Coefficient of Friction, Dynamic | 0.25 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Thermal Conductivity | in/hr/ft2 /°F | 1.7 | |

| CTE, linear | ASTM D696 | 1/K | 4.5x105 |

| Melting Point | ASTM D3418 | °F | 500 |

| Continuous Use | °F | 220 | |

| Deflection Temperature at 264psi | ASTM D648 | °F | 195 |

| Deflection Temperature at 66psi | ASTM D648 | °F | 390 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | ASTM D150 | 1MHz | 3.8 |

| Dielectric strength | ASTM D149 | V/mil | 350 |

| Surface resistivity | ASTM D257 | Ω/cm | ≥1013 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| FDA | Yes |