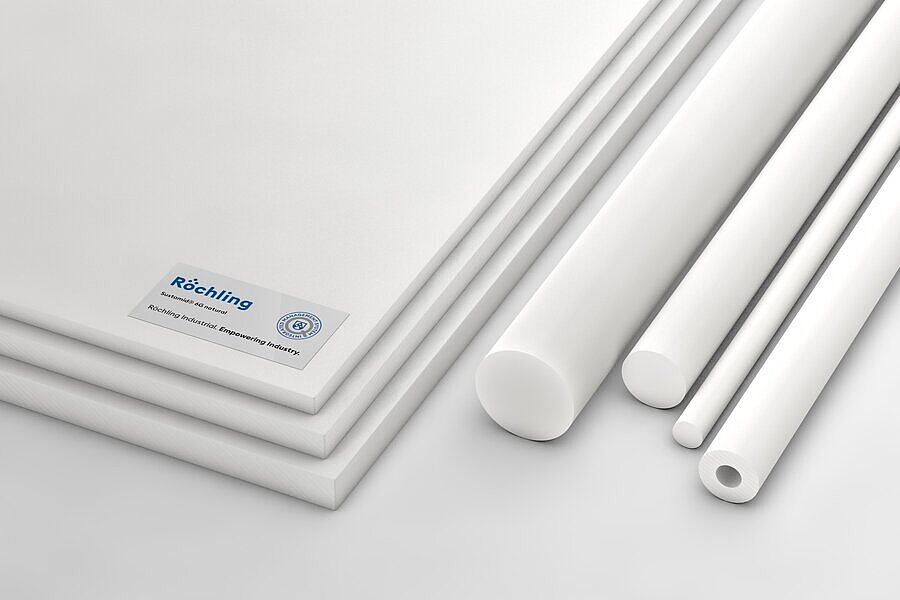

Sustamid® 6G - ASTM

PA — PA 6 G

Characteristics

- Good sliding properties

- Self-lubricating

- Low "stick-slip" effect

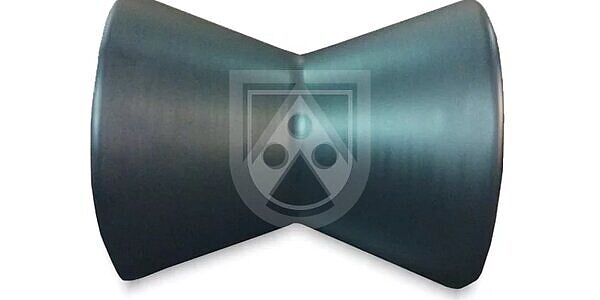

Application Examples

Technical Specifications Sustamid® 6G - ASTM

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | ASTM D792 | g / cm3 | 1.14 |

| Water Absorption | ASTM D570 | % | 8.5 |

| Water Absorption 24 hours | ASTM D570 | % | 1 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Hardness | ASTM D2240 | Shore D | 78 |

| Tensile Strength at yield 73°F | ASTM D638 | psi | 12000 |

| Tensile Modulus | ASTM D638 | psi | 550000 |

| Elongation at Break | ASTM D638 | % | 25 |

| Flexural Strength | ASTM D790 | psi | 15000 |

| Flexural Modulus | ASTM D790 | psi | 420000 |

| Compressive Strength | ASTM D695 | psi | 15500 |

| Rockwell Hardness | ASTM D785 | 85 | |

| Rockwell Hardness | ASTM D785 | R | 115 |

| Shear Strength | ASTM D732 | psi | 10500 |

| Izod Impact, Notched | ASTM D256 | ft-lb/in | 0.6 |

| Coefficient of Friction, Dynamic | 0.22 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Thermal Conductivity | in/hr/ft2 /°F | 1.7 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | in/in/°F x10-5 | 4.5 |

| Melting Point | °F | 450 | |

| Melting Point | ASTM D3418 | °F | 450 |

| Continuous Service Temperature, Air | °F | 200 | |

| Flammability, UL94 | 1/8 inch | HB | |

| Deflection Temperature at 264psi | ASTM D648 | °F | 195 |

| Deflection Temperature at 66psi | ASTM D648 | °F | 370 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | ASTM D150 | 1MHz | 3.8 |

| Dielectric strength | ASTM D149 | V/mil | 500 |

| Surface resistivity | ASTM D257 | Ω/cm | >1013 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| FDA | Yes | ||

| NSF | No | ||

| USDA | Yes |