Select a different country or region to see specific content for your location.

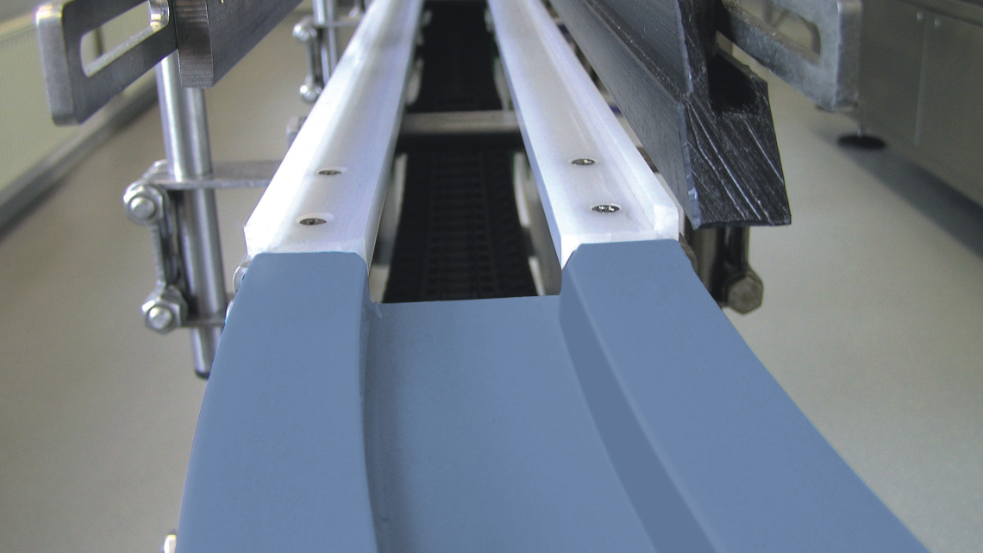

LubX® C Features

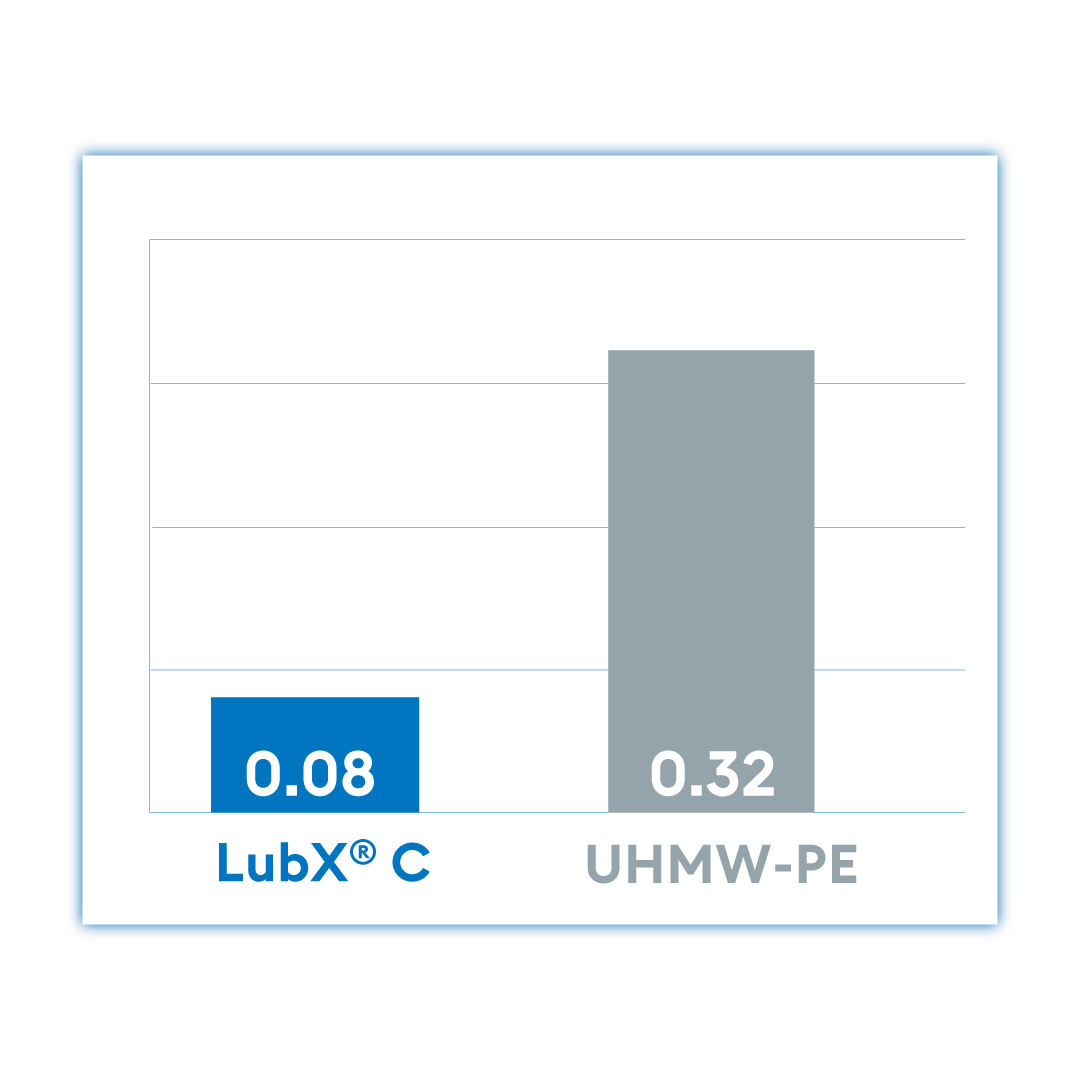

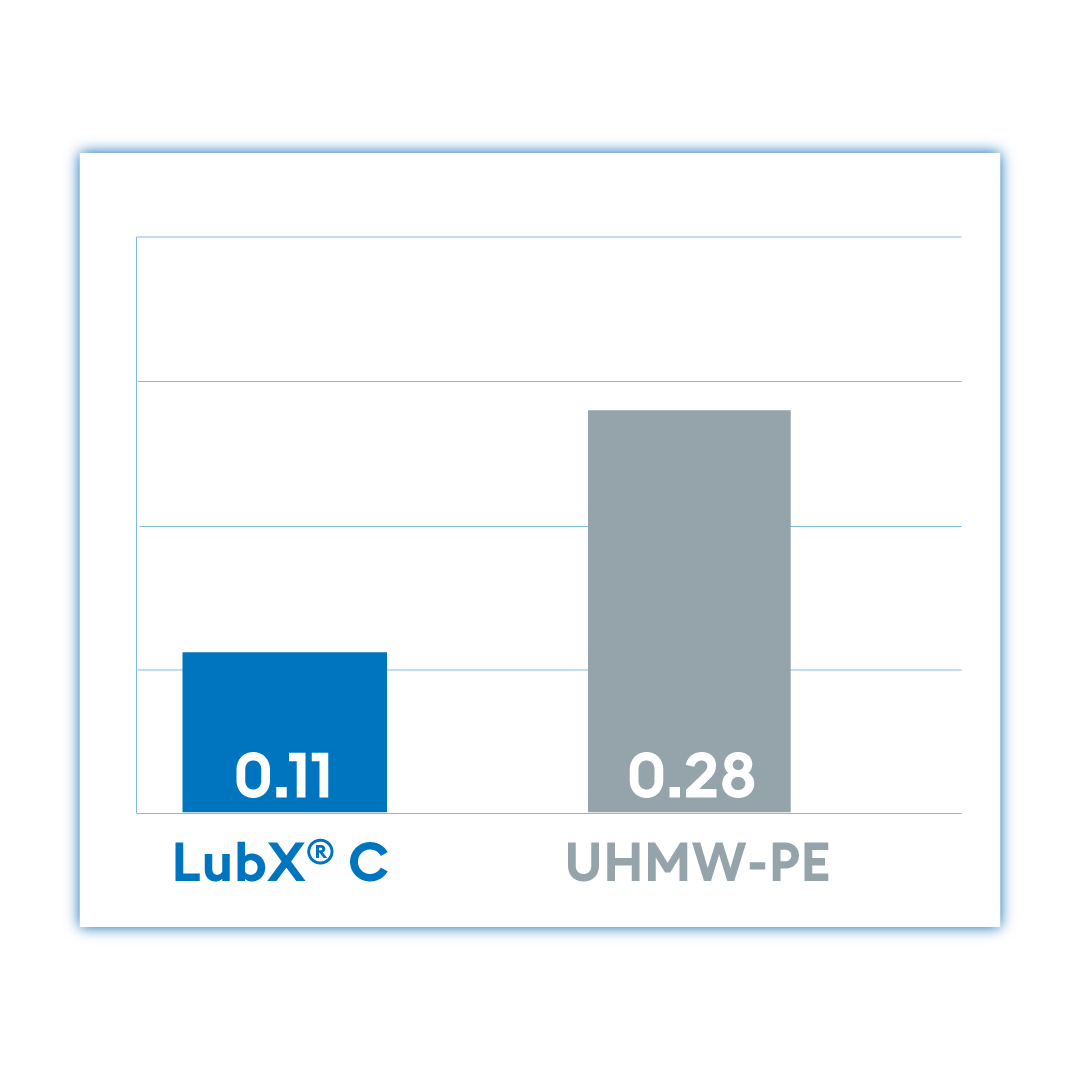

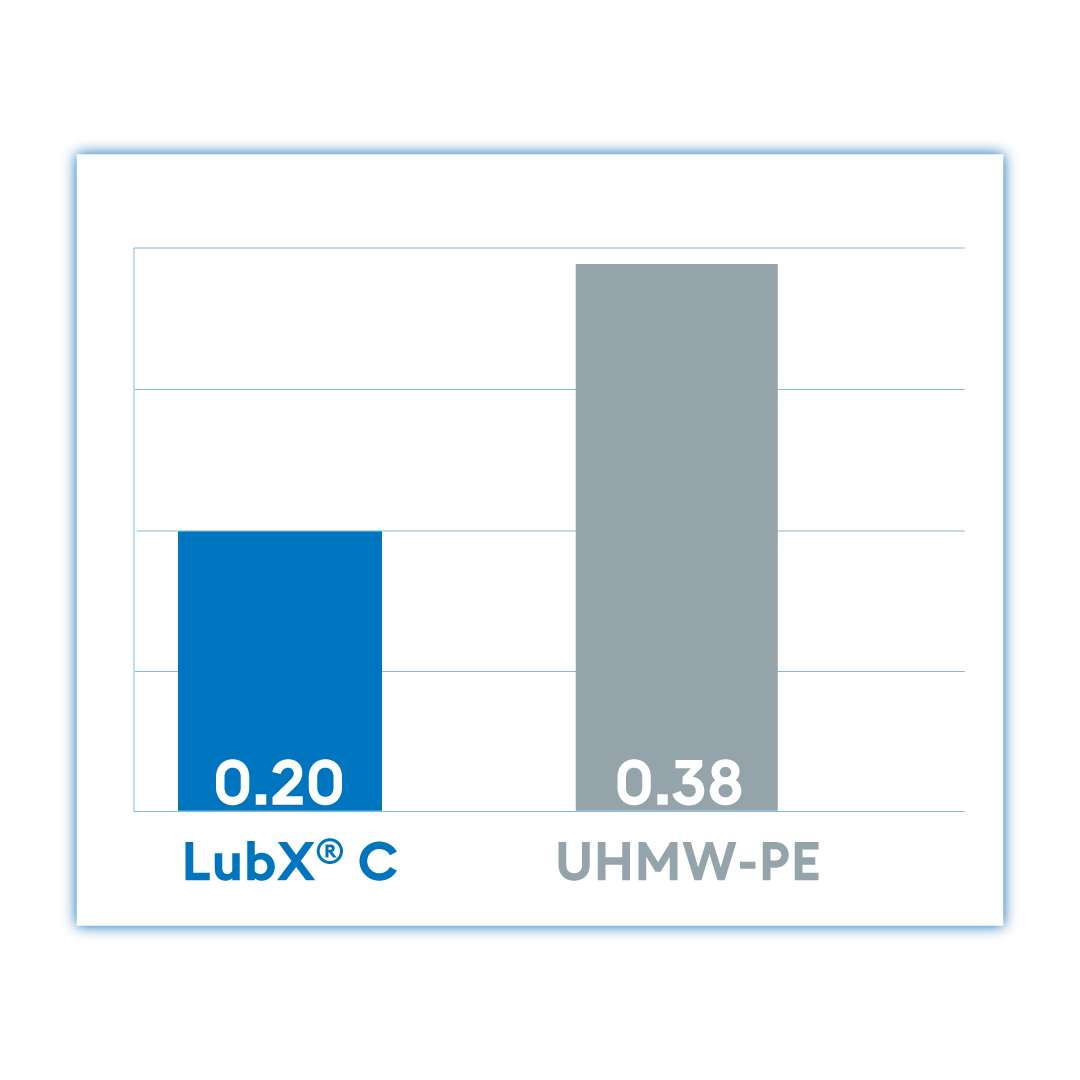

- Up to 75% lower coefficient of friction than standard UHMW-PE, requiring less energy to run conveyor systems

- Designed for increased efficiency when sliding against acetal (POM) and stainless steel/steel materials

- Reduces noise levels in factory environments, increasing overall safety for workers

- FDA compliant for use in food grade applications

- Reduces chances of stick-slip and backsliding

- Proprietary dry-running, self-lubricating formulation will not leach like traditional oil-filled materials, preventing dust and dirt build-up

- Increases process efficiency and stability