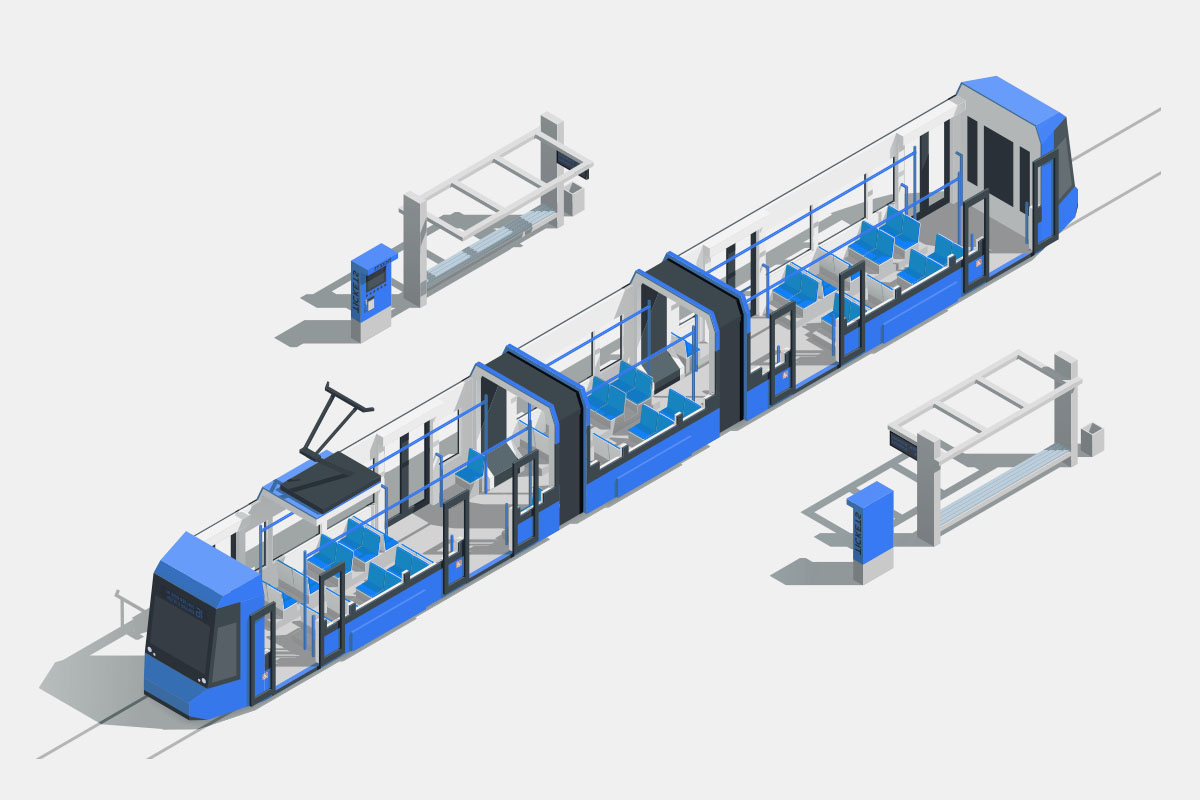

Ready-to-install components for rail vehicles

Range of systems: Engineering, production, painting, bonding, assembly & tailoring

Rail transport brings people and goods quickly and safely from point A to point B. Once on the rails, efficient and reliable technology is required. Every designer faces the challenge of developing economical, fast and safe rail vehicles. As a system supplier for components made of composite materials and thermoplastics, we support you all the way.

Efficient, safe & convenient

We have worked closely with leading vehicle manufacturers for decades. The focus is always on the central themes of transport for the future:

- Weight reduction & fuel efficiency

- Enhanced passenger safety

- Increased reliability & reduced maintenance times

- Improved riding comfort

Ready-to-install components

We manufacture ready-to-install components and entire assemblies made of thermosetting and thermoplastic materials according to your wishes and technical specifications.

Full service

On request, we can accompany you throughout theentire design and production process – from engineering, through bonding, screwing, painting and assembly, right through to the complete tailoring of installation-ready components.

Where our components are used:

Application areas:

- Trams and light rail

- People movers

- Subway / metros

- Commuter and regional trains

- Passenger carriages

- High-speed and intercity trains

- Locomotives

- Freight trains, freight wagons

Exterior

- External claddings

- Side skirts

- Exterior panelling

- Roof panels

- Roof cladding

- Portal cladding

- Apron flaps

Interior & floor

- Side wall cladding

- Cove flaps

- Ceiling panels

- Door pillar cladding

- Door mechanism covers

- Window pillar cladding

- Portal cladding

- Middle ceilings

- Side ceilings

- Seat shells

- Air ducts, air conditioning ducts

- Floor plates

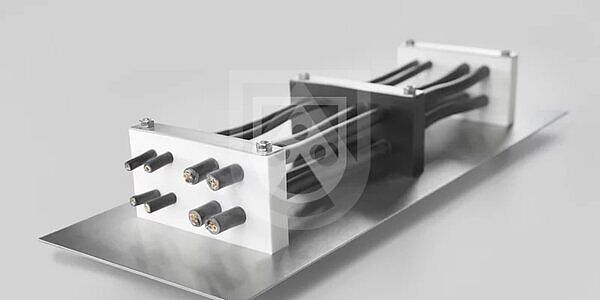

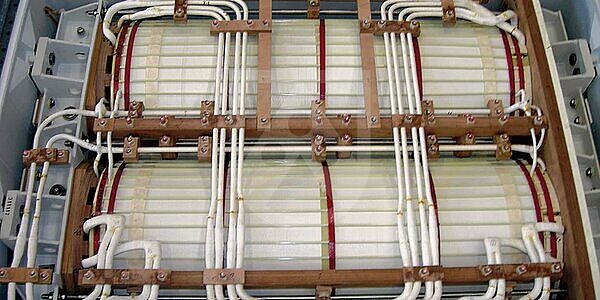

Technical parts

- Guide rails

- Spacer discs

- Wear plates

- Housing covers

- Cable clamps

- Insulation components

- Operating elements, e.g. for controllers

- Sliding elements

- Holders

- Spacer plates

- Pilots

Rail infrastructure

- Cable ducts

- Conductor rail supports

- Covers for 3rd rail

- Insulators

- Spacer plates under turnouts

- Signal and control covers (ETCS)

Lightweight, safe & efficient

A rail vehicle only earns money when it's moving. Together with our customers, we aim to increase efficiency, reduce maintenance times and optimise the safety and comfort for passengers and drivers.

High passenger safety

Fire protection

Depending on the material, our materials meet various standards for flame retardancy and thus contribute to a highlevel of safety for passengers and vehicle drivers. For instance:

- EN 45545

- NFPA 130: ASTM

- ASTM E162

- ASTM E662

- UL 94 V-0

- BSS 7239

- FAR 25.853

- JP Railway Ignition Test

- UL Yellow Card

Finding the right plastics for fire protection

Fire protection is essential in railway technology. However, blanket demands for materials that meet the highest hazard levels are not very productive. This limits the choice of materials unnecessarily and may not make economic sense. For this reason, the material must be individually selected for each requirement. But which plastics are suitable for which application?

Learn more about the selection of flame-retardant plastics for railway technology

Application examples

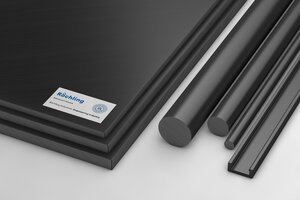

Related Products

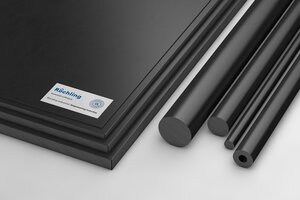

- GFK-UP

Durostone® UPM S13 LST

- PE > PE-UHMW - PE 1000

Polystone® M black

- PA > PA 6

Sustamid® 6 FR black

- PA > PA 6

Sustamid® 6 FR natural

- GFK-AG

Durostone® AGZ-S (160)

- GFK-UP

Durostone® PMP 325

- GFK-UP

Durostone® PMP 334

- PC - ABS

Maywoflamm® plus

- PA > PA 12 G

Lamigamid® 1207/1209

- PA > PA 12 G

Lamigamid® 1209

Our range of systems

Planned together, delivered ready to install

Together with our customers, we have been developing and producing components for rail vehicles for more than 40 years. Based on this experience, we know that each project must meet different requirements in terms of design, geometry, material properties as well as specifications and standards.

With our wide range of materials and products, worldwide locations and our full service, we have the highest degree of flexibility. Together with you, we develop and manufacture exactly the components you need for your rail vehicles and accompany you throughout the entire project from development to the ready-to-install component/assembly.

Full service

Our Corporate Research & Development department develops the optimum formulation for your application that meets the mechanical requirements as well as the demands on fire behaviour. Economic feasibility is always the focus here.

In our in-house CAD department, we develop the design of your components together with you. Our experienced technicians and toolmakers will coordinate with you on the feasibility and the highest possible fulfilment of the requirements for your individual application. Own tool and fixture construction allows very high flexibility for a variety of tasks.

Our quality management continuously monitors the production processes and checks the properties of the components in the company’s own material testing laboratory.

We are certified according to DIN 6701-2 (A1) for the bonding of railway vehicles and components. Our bonding specialists create high-strength, rigid and also elastic thick-bed adhesive joints. During assembly or pre-assembly, we integrate plug and screw connections made of different materials according to your specifications. We are also certified for welding rail vehicles according to EN 15085-2 (CL4).

Depending on the material, we can provide your components with paints or protective coatings as protection or visual enhancement. From simple protective functions to high-quality A1 surfaces – if necessary with protection against vandalism using anti-graffiti protective varnish – we produce high-quality surfaces for various requirements by means of different painting processes. Pre-treatments, primers and undercoats are individually matched to the base material and surface requirements of your component.

On request, you will receive completely tailored components from us. We carry out the mounting of electrical components, including cabling, and the installation of mechanical components.

We work with reusable or disposable packaging that meets special requirements for product protection and especially surface protection. This means that we can supply you with high-quality parts ready for installation directly to your assembly section.

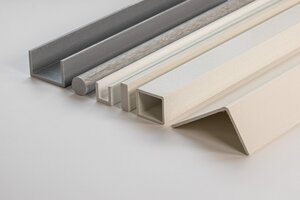

Variety of products and materials

Arrange technical advice

The performance of components for rail vehicles is determined by various influencing factors. These factors must be taken into account for the correct selection. For instance:

- Weight requirements

- Flame retardancy / fire behaviour

- Mechanical & thermal stress

- Electrical properties

- External influences such as UV radiation and weathering

- Design requirements, dimensions and tolerances

We would be happy to advise you on material selection, development and production of the right components for your application. Simply use our contact form at the bottom of the page or give us a call.