Pipeline technology

Transportation of crude and processed hydrocarbon products to and from refineries brings its own set of challenges. This includes thermal considerations, such as the need to suitably insulate the pipeline/tanks from the cryogenic (LNG) or high temperature (>120 °C) products being transported as well as to provide suitable corrosion and weather resistance. Our materials can help alleviate these challenges, due to the insulating nature of polymers. A number of our materials are suitable for prolonged use at cryogenic temperatures; with other grades suitable for high temperatures (+150 °C) and some even suitable for use up to +500 °C. This is coupled with polymers naturally low thermal conductivity, meaning they are excellent insulators. Corrosion protection of equipment and pipeline support structures, by replacing metallic components with thermoplastics and composites can also lead to increased part lifetimes.

Your advantages

- Long-lasting: Resistant to corrosive salt water, oil, gas and resources

- Low maintenance due to wear resistance and tribological properties

- Corrosion and weather resistant

- Weight reduction allows easier install/access

- Noise reduction during operation

Typical applications

- Pipe-in-pipe centralisers

- Pipe-lay equipment (diablo rollers)

- Pipe supports (topside and subsea)

- Thermal insulation

- Corrosion protection

- Fasteners

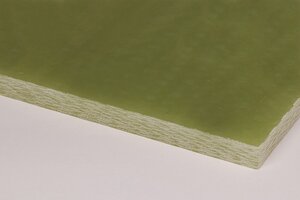

- GFK-EP

Durostone® EPR S7

- GFK-EP

Durostone® Tubes EPC 22

- GFK-EP

Durostone® Tubes EPC 22H

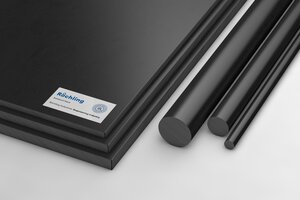

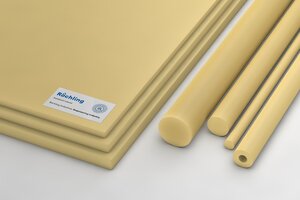

- PA > PA 6 G

Sustamid® 6G MO black

- PA > PA 6 G

Sustamid® 6G natural

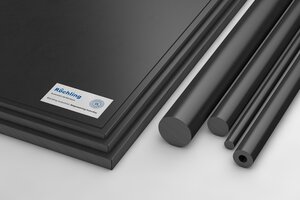

- Other

Durolight® S

- Other

Durolight® S1

- Other

Durolight® S2

- Other

Durolight® S3

- Other

Durolight® S7

- Other

Glastherm® HT 200

- Other

Glastherm® HT 200 (SMC)

- Other

Glastherm® HT 220

- Other

Glastherm® HT 250 HQ

- Other

Glastherm® HT 250 M

- Other

Glastherm® HT 300

- Other

Glastherm® HT 500

- Other

Glastherm® HT LC

- Laminated Densified Wood

Lignostone® H

Arrange technical advice

The performance and reliability of materials used in the design for pipelines are influenced by a variety of factors. These criteria need to be considered in order to make the right choice. Examples:

- Extreme weather conditions (UV) and abrasion (sand/waves).

- Contact with corrosive seawater.

- Tribological requirements (friction and wear).

- Mechanical demands.

- Thermal cycling/exposure to both high and low temperatures.

- Exposure to demanding hydrocarbon fluids, (H2S, production fluids, greases).

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.