Select a different country or region to see specific content for your location.

Diagnostics

Plastic materials and parts for Diagnostics

Materials and parts for Diagnostics

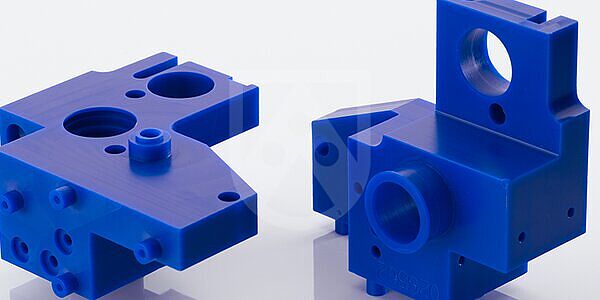

If you are a medical device manufacturer or laboratory engaged in the diagnosis and treatment of illness, we have a range of products and services supporting your requirement for biologically inert materials and products. Machined parts with the most demanding level of accuracy and cleanliness:

Design and material advice

Prototype production

Demanding geometries

Bespoke quality control

Typical parts include

Extraction spacers

Load lack chambers

Manifolds

Housings

Connectors

Plate guides

Application examples

The performance and service life of materials used in the healthcare sector are influenced by a variety of factors. When choosing the right material, factors such as surface quality requirements, contact with cleaning agents, disinfectants, dimensions and/or tolerances are essential.

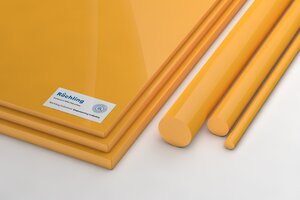

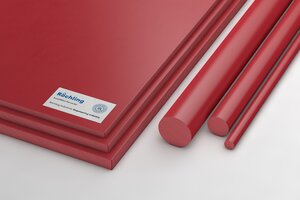

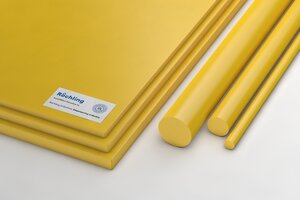

Selection of Medical Grade Products

- PEEK

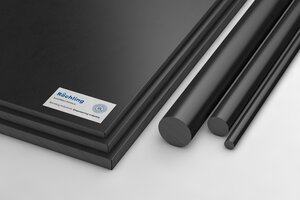

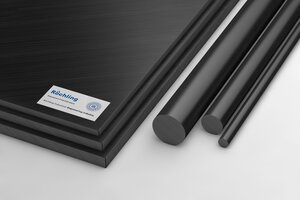

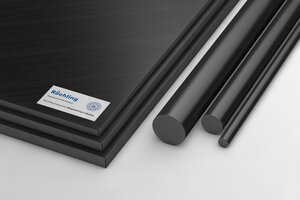

SustaPEEK MG black

- PEEK

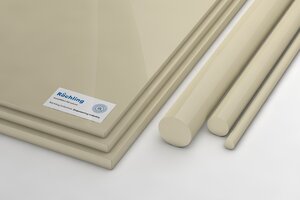

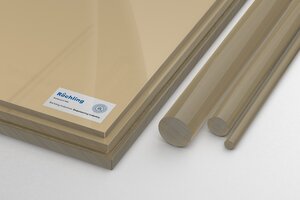

SustaPEEK MG natural

- PEEK

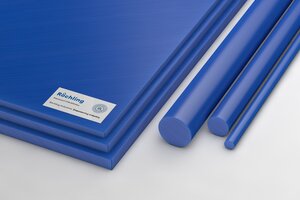

SustaPEEK MG blue BL

- PEEK

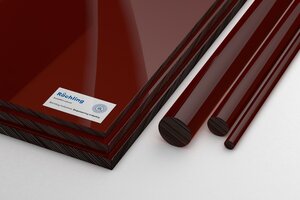

SustaPEEK MG red RD

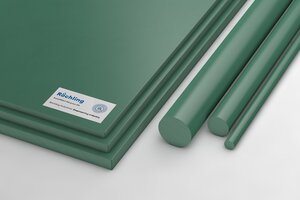

Selection of Healthcare Grade products

- PE > PE-HD - PE 300

Polystone® G HG white

- PVDF

SustaPVDF HG natural