Sliding friction in conveying systems has a decisive influence on the energy consumption of installations. Röchling are intensely concerned with the attendant problems and have developed the LubX® materials that revolutionise the slide systems in materials-handling and automation technologies.

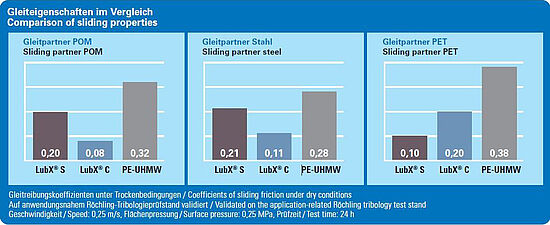

With LubX® S and LubX® C, Röchling Engineering Plastics is offering two new high-performance materials, which have outstanding dry-running properties at their disposal. Compared with conventional anti-friction materials, conveying systems equipped with LubX® need considerably less energy. The up to 75% lower coefficient of friction of LubX® reduces the risk of the slip-stick effect (back-sliding) almost completely and thus increases process stability.

- LubX® S is especially aligned to the sliding partner PET, particularly beverage bottles.

- LubX® C is especially aligned to POM and steel, by way of example, chain conveyors.

Tribological systems

In the development of LubX® products, great care has not only been taken to minimise the coefficient of friction of the sliding materials, but also to consider the tribological system of the sliding partners in an integrated manner and especially aligned to the particular specific requirements concerned. The individual motion and transport segments of different conveying systems were analysed, and the relative movements of the elements and the frictional forces arising at the points of contact examined. These frictional forces have a decisive impact on the performance of the conveying system.

Energy efficiency

With energy prices rising in the long term, lowering energy costs plays an increasingly more important role in the project planning of production, storage and logistic processes. When utilising components with optimized sliding properties in conveying processes, the conveying power required – and thus the energy applied – may be reduced to a minimum. The performance and efficiency of the plant can thus be considerably enhanced.

Our own pilot plants

Röchling Engineering Plastics KG has several modular-designed test with which conveying processes can be tested under real conditions. We utilise a tribology test stand developed in co-operation with scientists in our materials laboratory for the necessary preliminary examinations of the materials to be tested on it. In the development of LubX® materials, this enabled the individual parameters to be exactly tested and even minimum improvements identified, which then targeted the further direction of development.

If you want to know more, please don’t hesitate to talk to your Röchling counterpart or write us on: lubx @roechling-plastics .com

We will be only too glad to inform you.

Here you can download the new LubX® brochure.