Our Capabilities

Custom Metal Components From Our Lancaster Site

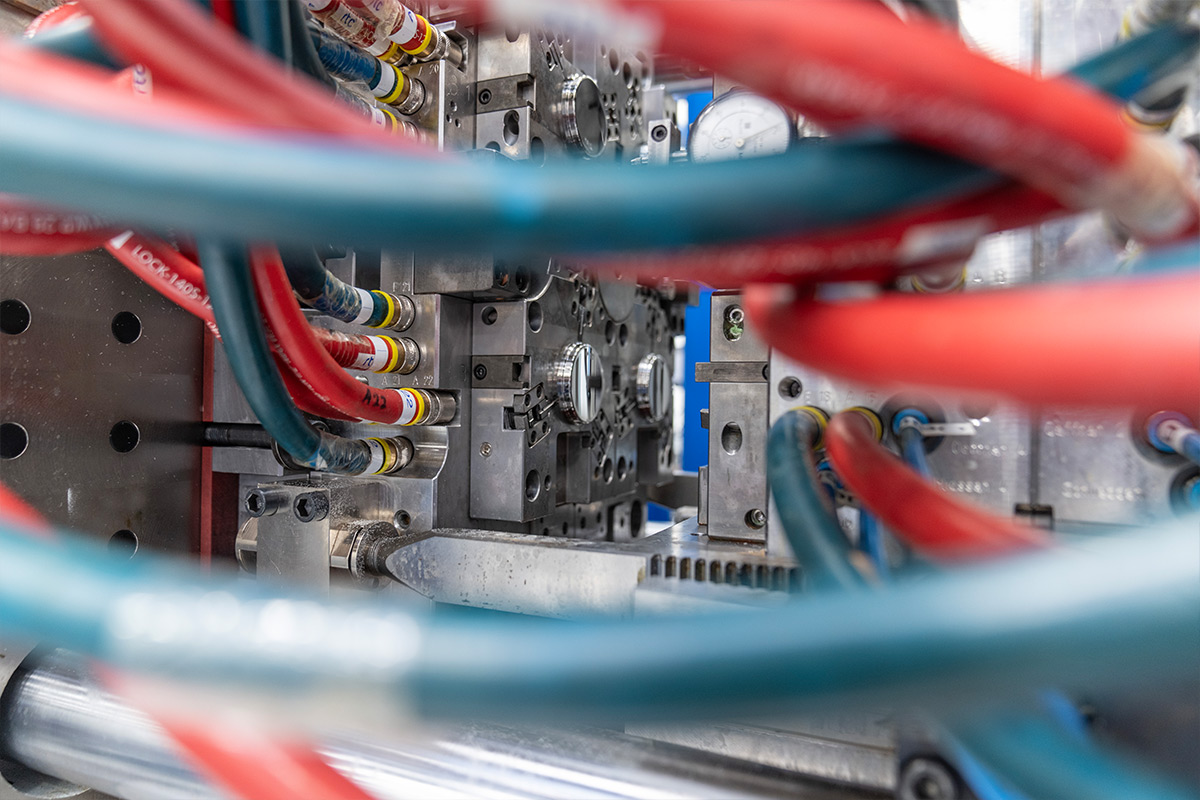

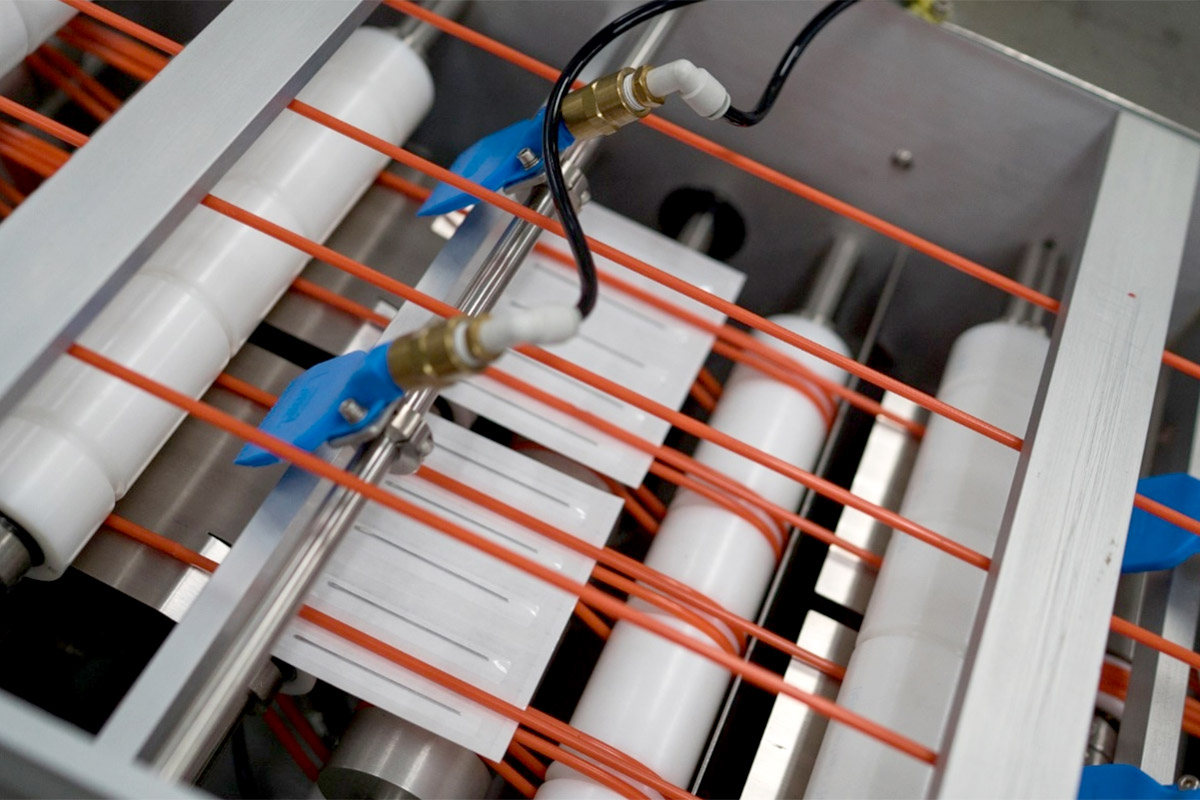

Metal processing is a core expertise offered by Röchling Medical Lancaster, USA for OEMs looking for custom metal applications. The Lancaster site is particularly well versed in the development of custom needles and cannula along with non-tubular devices.

Metal Processing Capabilities:

- Cannula Grinding & Pointing

- Wire EDM Machining

- Micromachining

- Laser Cutting (Holes, Slits, Slots...)

- Laser Welding and Marking

- Tipping, Flaring, Forming, Swaging

- Metal Stamping & Coining

- Micro Welding

- Hypodermic Needle Manufacturing

- Swiss Turn Machining

Combining Metal & Plastic Processing

Expertise for the Manufacture of Complete Devices

In addition, plastic injection over molding is an in-house expertise that is regularly used to add value and increase the functionality of a metal device. Secondary operations such as electro polishing, passivation or metal washing operations are available to ensure your product meets its final specifications. Our engineering team continually challenges the limits of both the material and processing equipment to create highly complex configurations to meet our customer’s market requirements.

Titanium Processing

Excellent Material for Medical Applications

The qualities of titanium are superior to most other materials for certain medical applications:

- Non-toxic, biocompatible (no rejection by the body tissue)

- Durable

- Resistant to corrosion

- Non-magnetic (MRI-safe)

- Low density but strong (lighweight alternative to steel)

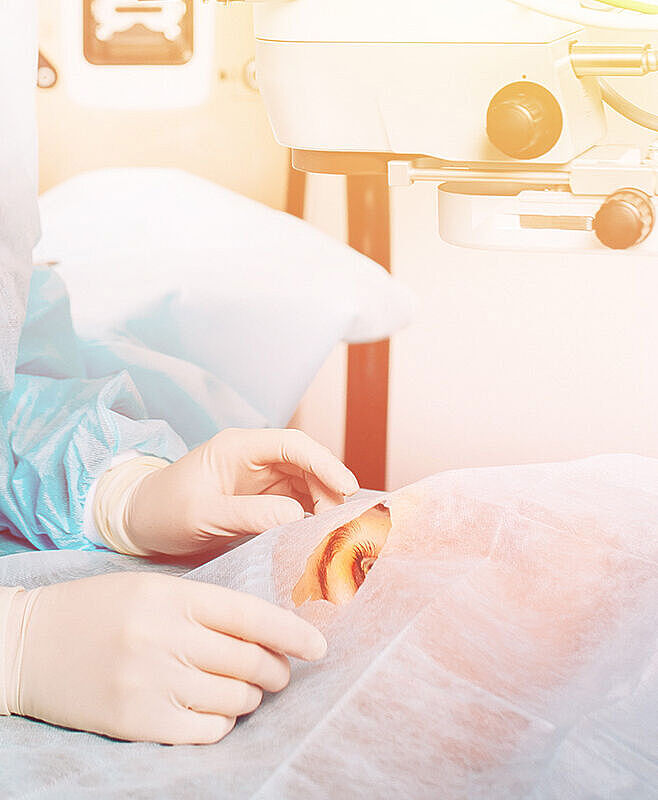

This makes it particularly interesting for applications in a number of medical fields for example, dental implants, joint replacements, surgical instruments and medical devices.

Our Titanium Processing Capabilities

At our Lancaster site, we have the capabilities and specific expertise required for the machining of titanium parts and components for use in medical devices. CNC machining is the manufacturing technique of choice when processing titanium. We use the latest Swiss milling technology to machine very complex parts with tight tolerances, for example for ophthalmic and surgical applications.

Competences at the Following Locations

Case Studies

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created with them.

Metal and Plastic Processing from a Single Source

Medical Device Contract Manufacturing

Further Technologies

At our global locations, we cover a wide range of manufacturing technologies, enabling us to find a suitable, customized solution for individual requirements.

Contact Us

For more information about our competences in metal processing for medical applications, please contact our team.

We look forward to hearing from you.

Your Contact

Bill Ruth

Vice President - Sales & Marketing