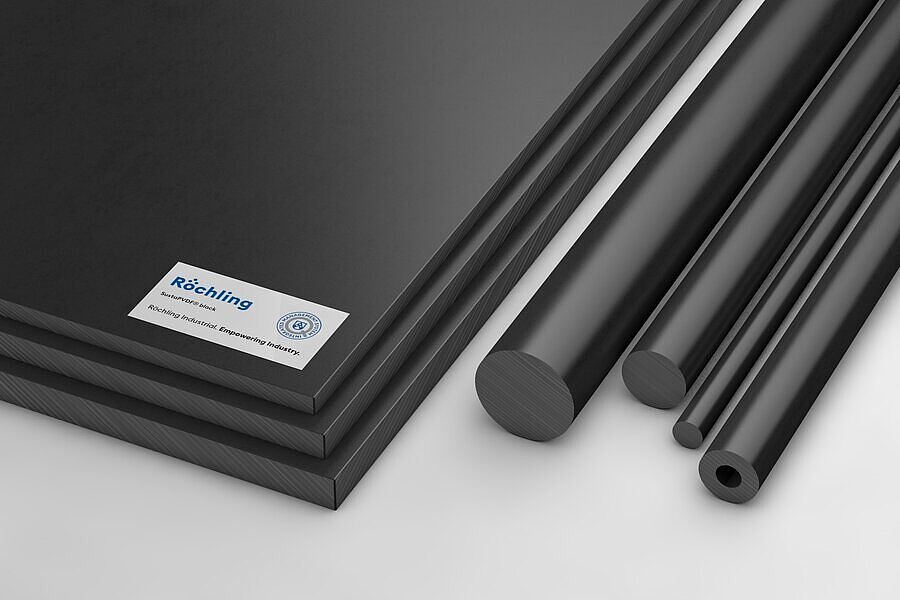

SustaPVDF black

PVDF

black

rod

Characteristics

- High purity

- High tensile strength

- High stiffness

- High cold impact strength

- Good weldability

- High continuous service temperature

- Electrically insulating

- Chemical resistant

- Good thermoformability

- Good weather resistance

Industries

- Food Industry

Application Examples

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 610755 | SustaPVDF black extruded | rod | rod | black | Ø 70 x 1000 mm | 1,000 mm | 70 mm | |||

| No stock item (MOQ) | 650305 | SustaPVDF black extruded | rod | rod | black | Ø 170 x 2000 mm | 2,000 mm | 170 mm | |||

| No stock item (MOQ) | 650306 | SustaPVDF black extruded | rod | rod | black | Ø 170 x 1000 mm | 1,000 mm | 170 mm | |||

| No stock item (MOQ) | 709077 | SustaPVDF black extruded | rod | rod | black | Ø 170 x 3000 mm | 3,000 mm | 170 mm | |||

| No stock item (MOQ) | 920322 | SustaPVDF black extruded | rod | rod | black | Ø 8 x 3000 mm | 3,000 mm | 8 mm | |||

| No stock item (MOQ) | 927120 | SustaPVDF black extruded | rod | rod | black | Ø 35 x 1000 mm | 1,000 mm | 35 mm | |||

| No stock item (MOQ) | 927399 | SustaPVDF black extruded | rod | rod | black | Ø 25 x 3000 mm | 3,000 mm | 25 mm | |||

| No stock item (MOQ) | 927592 | SustaPVDF black extruded | rod | rod | black | Ø 70 x 3000 mm | 3,000 mm | 70 mm | |||

| No stock item (MOQ) | 929976 | SustaPVDF black extruded | rod | rod | black | Ø 45 x 3000 mm | 3,000 mm | 45 mm |

Technical Specifications SustaPVDF black

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 1,78 |

| Water absorption | DIN EN ISO 62 | % | 0,0 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | V0 / V0 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | 55 |

| Elongation at break | DIN EN ISO 527 | % | 30 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 2100 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | 12 |

| Shore hardness | DIN EN ISO 868 | scale D | 80 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 178 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,2 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,20 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 140 |

| Service temperature, long term | Average | °C | -20 … 140 |

| Service temperature, short term (max.) | Average | °C | 150 |

| Heat deflection temperature | DIN EN ISO 75, Verf. A, HDT | °C | 115 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Dielectric constant | IEC 60250 | 9 | |

| Dielectric dissipation factor (50 Hz) | IEC 60250 | 0,02 | |

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | 1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | 1014 |

| Comparative tracking index | IEC 60112 | 600 | |

| Dielectric strength | IEC 60243 | kV / mm | 21 |