EtroX® I CM natural

PI

The premium product for highly demanding applications

Our premium material EtroX® I CM was specially developed to meet the high demands of the electronics, aerospace and automotive industries. As a pure polyimide, it withstands particularly high temperatures. EtroX® I CM can be used to design components that offer significant advantages over other thermoplastics.

natural

sheet

Characteristics

- Heat resistant

- High mechanical strength

- Low creep tendency

- High impact resistance

- High stiffness

- Good dimensional stability

Industries

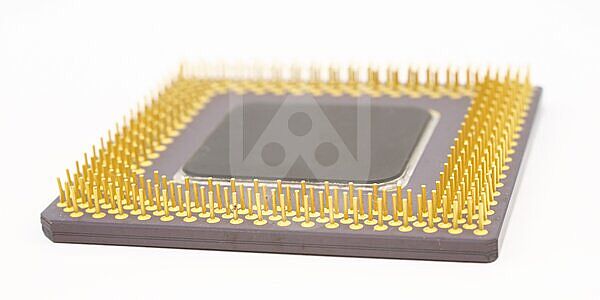

- Semiconductor Front-End applications

- Semiconductor Wafer Handling

- Semiconductor Back-End applications

- Semiconductor High and low temperature

- Semiconductor Dicing

Application Examples

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 685684 | EtroX® I CM natural pressed | sheet | sheet | natural | 16 x 395 x 395 mm | 395 mm | 395 mm | 16 mm | ||

| No stock item (MOQ) | 708159 | EtroX® I CM natural pressed | sheet | sheet | natural | 8 x 395 x 395 mm | 395 mm | 395 mm | 8 mm | ||

| No stock item (MOQ) | 708181 | EtroX® I CM natural pressed | sheet | sheet | natural | 10 x 395 x 395 mm | 395 mm | 395 mm | 10 mm | ||

| No stock item (MOQ) | 728345 | EtroX® I CM natural pressed | sheet | sheet | natural | 12 x 395 x 395 mm | 395 mm | 395 mm | 12 mm | ||

| No stock item (MOQ) | 742252 | EtroX® I CM natural pressed | sheet | sheet | natural | 20 x 395 x 395 mm | 395 mm | 395 mm | 20 mm | ||

| No stock item (MOQ) | 743535 | EtroX® I CM natural pressed | sheet | sheet | natural | 45 x 395 x 395 mm | 395 mm | 395 mm | 45 mm | ||

| No stock item (MOQ) | 745872 | EtroX® I CM natural pressed | sheet | sheet | natural | 35 x 395 x 395 mm | 395 mm | 395 mm | 35 mm | ||

| No stock item (MOQ) | 746940 | EtroX® I CM natural pressed | sheet | sheet | natural | 44 x 395 x 395 mm | 395 mm | 395 mm | 44 mm | ||

| No stock item (MOQ) | 749009 | EtroX® I CM natural pressed | sheet | sheet | natural | 6 x 395 x 395 mm | 395 mm | 395 mm | 6 mm | ||

| No stock item (MOQ) | 749010 | EtroX® I CM natural pressed | sheet | sheet | natural | 13 x 395 x 395 mm | 395 mm | 395 mm | 13 mm | ||

| No stock item (MOQ) | 754005 | EtroX® I CM natural pressed | sheet | sheet | natural | 15 x 395 x 395 mm | 395 mm | 395 mm | 15 mm | ||

| No stock item (MOQ) | 755811 | EtroX® I CM natural pressed | sheet | sheet | natural | 9 x 395 x 395 mm | 395 mm | 395 mm | 9 mm | ||

| No stock item (MOQ) | 856705 | EtroX® I CM natural pressed | sheet | sheet | natural | 25 x 395 x 395 mm | 395 mm | 395 mm | 25 mm | ||

| No stock item (MOQ) | 868344 | EtroX® I CM natural pressed | sheet | sheet | natural | 40 x 395 x 395 mm | 395 mm | 395 mm | 40 mm | ||

| No stock item (MOQ) | 883159 | EtroX® I CM natural pressed | sheet | sheet | natural | 60 x 395 x 395 mm | 395 mm | 395 mm | 60 mm |

Technical Specifications EtroX® I CM natural

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 1,37 |

| Water absorption | DIN EN ISO 62 (23°C / 24h) | % | 0,6 |

| Water absorption | DIN EN ISO 62 (23°C / 48h) | % | 0,8 |

| Water absorption | DIN EN ISO 62 (23°C / 3 Weeks) | % | 2,4 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Elongation at break | DIN EN ISO 527 | % | 8 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 3600 |

| Tensile strength | DIN EN ISO 527 | MPa | 145 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | 10 |

| Shore hardness | DIN EN ISO 868 | scale D | 89 |

| Ball indentation hardness | DIN EN ISO 2039-1 | MPa | 240 |

| Elastic modulus of compression | DIN EN ISO 604 | MPa | 4200 |

| Tensile creep modulus, 1h | ISO 899-1 | MPa | 3390 |

| Tensile creep modulus, 1000h | ISO 899-1 | MPa | 2730 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Glass transition temperature | ISO 11357-3 | °C | 323 |

| Service temperature, short term (max.) | Average | °C | 380 |

| Mean coefficient of linear thermal expansion | ISO 11359-2 | K-1 | 41 |

| Heat deflection temperature | DIN EN ISO 75 | °C | 319 |

| Temp. of deflection under load, 1.80 MPa | ISO 75-1/-2 | °C | 319 |

| Temp. of deflection under load, 0.45 MPa | ISO 75-1/-2 | °C | 343 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | > 1015 |

| Dielectric constant @ 100Hz | IEC 60250 | 4,2 | |

| Dielectric constant @ 1kHz | IEC 60250 | 4,2 | |

| Dielectric constant @ 10kHz | IEC 60250 | 4,1 | |

| Dielectric constant @ 100 kHz | IEC 60250 | 4,1 | |

| Dielectric constant @ 10GHz | IEC 61189-2-721 | 3,4 | |

| Dielectric constant @ 40GHz | IEC 61189-2-721 | 3,3 | |

| Dielectric constant @ 100GHz | IEC 61189-2-721 | 3,2 | |

| Specific Volume resistivity | IEC 60093 | Ωm | 8*1013 |

| Specific Surface resistivity | IEC 60093 | Ω | 5*1015 |

| Relative permittivity, 100Hz | IEC 62631-2-1 | - | 3,5 |

| Relative permittivity, 1MHz | IEC 62631-2-1 | - | 3,4 |

| Dissipation factor, 1 MHz | IEC 62631-2-1 | E-4 | 80 |

| Electric strength | IEC 60243-1 | kV / mm | 34 |