Reliable solutions for industrial baked goods production

In the industrial manufacturing and processing of baked goods and confectionery, components made from specially developed materials are crucial to the performance and durability of machinery and systems.

Engineers are challenged to design systems that remain efficient, low-maintenance, and easy to clean – even after countless hours of operation.

Our advanced engineering plastics are tailored to meet exactly these requirements and are approved for direct food contact under EU Regulation 10/2011/EU and FDA.

They significantly increase the efficiency of portioning machines, spiral freezers, and packaging systems, and offer excellent resistance to cleaning agents as well as high wear resistance – even under extreme temperatures.

Typical areas of application

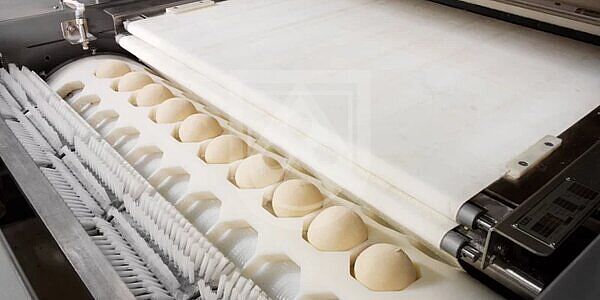

- Portioning equipment

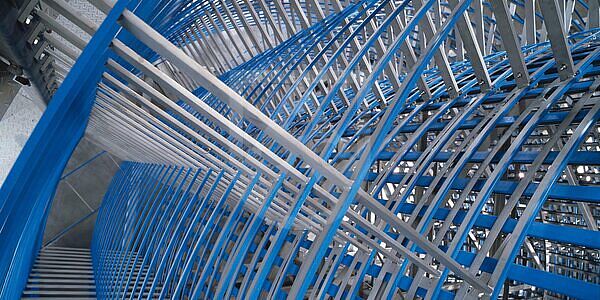

- Spiral freezers

- Packaging systems

- Conveyor systems

Smart solutions for industrial bakery and confectionery production

Our new, smart materials have been specially developed for the food industry and offer intelligent solutions that meet the demands of modern production.

Count on quality – enhanced by innovative technology.

Smart materials – ID

Your standard material is now smart!

By adding tiny fluorescent marker particles directly into the plastic, your component becomes identifiable – verifiable as your original part.

The “ID” suffix clearly indicates the presence of these innovative marker particles.

EU & FDA approval

Our materials meet the strict requirements of EU Regulation 10/2011/EU and the FDA, and are approved for direct contact with food.

They ensure maximum reliability and safety in critical food production environments.

Your commitment to food safety and reliability

Our plastics marked with SmartMarker® offer outstanding reliability for applications in the food industry. They are certified for direct food contact and meet the standards of EU Regulation 10/2011/EU and the FDA.

Our materials

- Sustarin® C ID

- Polystone® D ID

- Sustadur® PET ID

- Sustamid® 6 ID

- SustaPEEK ID

*Other materials are also available as SmartMarker® variants upon request.