Long last plastics for Topside Equipment

Oil & Gas production in offshore environments puts materials under some of the most demanding conditions found on the planet. These often include intense UV radiation, corrosive salt water and abrasive sand (winds), not to mention the extreme thermal conditions found in both arctic and tropical environments. Yet all environments require the safe and efficient operation of equipment every time. Our wide material range meets these requirements and more, no matter where the equipment operates. Our grades are weather resistant; to intense UV conditions and wear from sand and splash zone applications. Compared to steel, our materials do not require the need for sacrificial cathodic protection and offer weight savings of up to 70%! This leads to a reduction on the loads of the secondary support structures and can lead to an increase in operational efficiency. This combination allows you the construction of longlasting equipment and offers significant efficiency and economic advantages, no matter your application.

Your advantages

- Naturally corrosion resistant materials

- UV and weather resistant

- Long-lasting and low maintenance: resistant to corrosive salt water and hydrocarbons

- Weight reduction (easier install/usage)

- Noise reduction during operation

Typical areas of application

- Launch and Recovery Systems (LARS)

- Clamps

- Thermal insulation (including structural)

- Sensor body housings

- LNG transportation

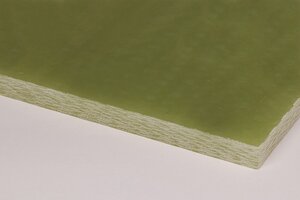

- GFK-EP

Durostone® EPM S7

- GFK-EP

Durostone® EPR S1

- GFK-EP

Durostone® EPR S7

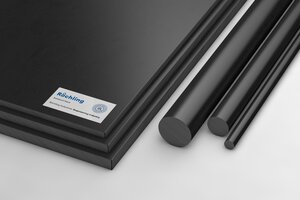

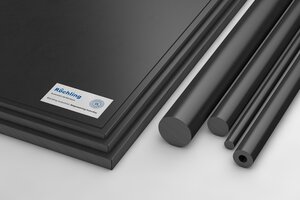

- PA > PA 6 G

Sustamid® 6G MO black

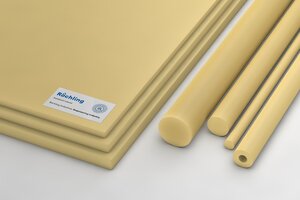

- PA > PA 6 G

Sustamid® 6G natural

Arrange technical advice

The performance and reliability of materials used for the design of machines and systems in topside applications are influenced by a variety of factors. These criteria need to be considered in order to make the right choice. Examples:

- Thermal cycling/exposure to both high and low temperatures

- Contact with corrosive seawater

- Exposure to demanding hydrocarbon fluids, (H2S, production fluids, greases)

- Extreme weather conditions (UV) and abrasion (sand/waves)

- Mechanical demands

- Tribological requirements (friction and wear)

- Weight

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.