Downhole components

Downhole environments are some of the most demanding involved with oil & gas production. With a cocktail of chemicals such as hydrocarbons, H2S, production fluids, lubricants and grease in combination with high temperatures (>120 °C) present. Depending on the exact environmental conditions, we can advise you on the suitability of engineering plastics or high temperature materials for your application. We also offer tribologically optimised materials, with modifications to further increase part life by improving abrasion resistance. Whilst reducing the coefficient of friction can leaded to reduced maintenance intervals and improved equipment efficiency. We are also able to offer a number of grades which meet qualification requirements such as NORSOK.

Your advantages

- Long-lasting and low maintenance: due to excellent chemical resistant

- Economic production processes

- Increased sealing efficiency

- Reduced risk of damage to critical (riser) equipment

Typical areas of application

- Seal and valve seats

- Back-up rings

- Frac balls

- Centralisers

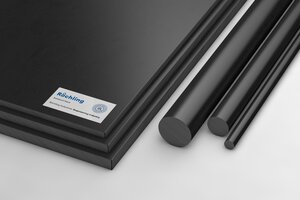

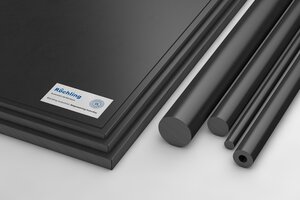

- PA > PA 6 G

Sustamid® 6G MO black

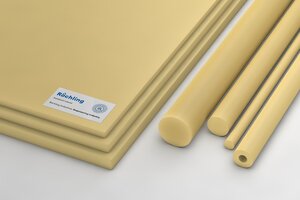

- PA > PA 6 G

Sustamid® 6G natural

Arrange technical advice

The performance and reliability of materials used in the design of machines and systems in downhole applications are influenced by a variety of factors. These criteria need to be considered in order to make the right choice. Examples:

- Exposure to demanding hydrocarbon fluids, (H2S, production fluids, greases)

- Tribological requirements (friction and wear)

- Mechanical demands

- Thermal cycling/exposure to both high and low temperatures

- Contact with corrosive seawater

- Extreme weather conditions (UV) and abrasion (sand/waves)

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.