Cleanroom Extrusion

Custom Solutions for Sophisticated Requirements

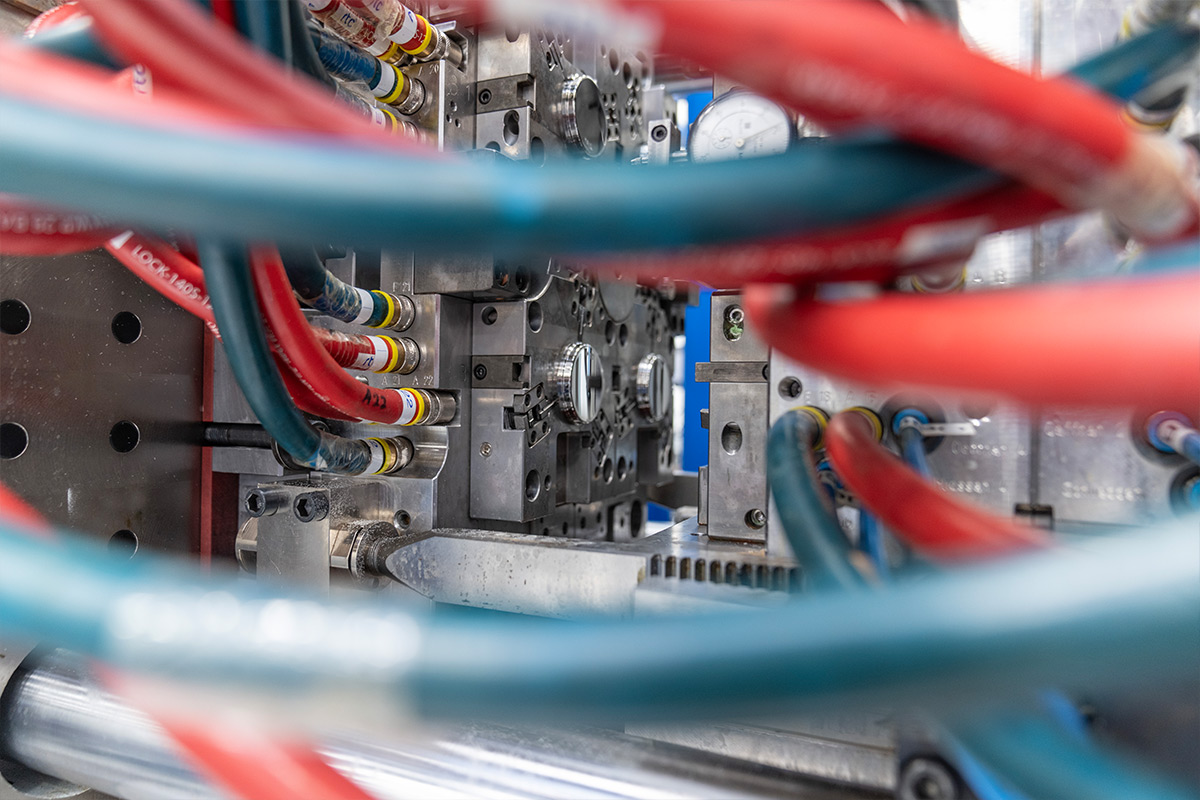

We manufacture extruded hoses, tubes and profiles for a wide range of medical applications under ISO 8 cleanroom conditions. To keep pace with the rapid trends and developments in the medical technology market, we continuously invest in innovative production technologies and in expanding our know-how. Therefore, we can offer special expertise in processes such as co-extrusion or the development and production of multilayer tubes, also with braiding, as required.

Our Range of Expertise in Cleanroom Extrusion

- Processing of standard polyolefin plastics and engineering plastics

- Co-extrusion and production of multilayer tubes with braidings

- Inline processing methods such as punching, drilling, gluing, printing, machining and non-cutting cutting technology

- Profile lengths from 10 - 7500 mm

- Output performance from 0.2 kg/h up to 170 kg/h

- Part weights from 0.5 - 4500 g/m

- Single-layer tubes Ø 0.50 - 12.00 mm

- Coatings Ø 0.50 - 12.00 mm

- Wall thickness from 0.10 - 5.00 mm

Multilayer Structure & Material Combinations

Due to the multilayer structure of fabric-reinforced hoses, the advantageous properties of individual layers, e.g., in terms of flexibility, optimized sliding friction and compressive strength, can be matched to one another and cleverly combined in the multistage production process. The overall system can thus be optimally adjusted to the application-specific requirements.

In addition to biocompatible plastics, plastic-based monofilaments (e.g., of polyester) and stainless steel wires are used as reinforcing fabrics (braids).

In this way we can meet a wide range of requirements for hoses in medical applications:

- Buckling stability and torsional stiffness – even with extremely small product dimensions

- Compressive strength

- Adjustable linear expansion

- Flexibility

- X-ray permeability

- Optimized sliding properties

Because of their advantages, our fabric-reinforced hoses are already widely used by customers in the fields of bronchoscopy and urology. With our process engineering know-how, we can develop the perfect solution for your individual requirements.

Competences At The Following Locations

Further Technologies

At our global locations, we cover a wide range of manufacturing technologies, enabling us to find a suitable, customized solution for individual requirements.

Contact Us

For more information about our competence in medical extrusion and custom design options, please contact our team.

We look forward to hearing from you.