Precision Components

Precision in the smallest detail with highly functional plastic components. From microplastic parts to metal-plastic hybrids and complex assemblies, we offer forward-looking injection molding solutions.

Our expertise ranges from automated manufacturing with high cleanliness standards to global series production for industries such as automotive, industrial, medical, defense and household.

Our Processes

Our core process is injection molding, which we use to mass-produce high-precision plastic parts. This is supplemented by numerous other processing steps that ensure impeccable quality.

For example, we ensure precise contours with punches, purity with washing and insulation, and optimum material properties with conditioning and irradiation.

Processes such as trowalizing refine surfaces, while marking and printing enable clear traceability.

In addition, we rely on fully automatic assembly, which extends to automated placement in trays and blisters.

Another focus is on in-line quality assurance, which ranges from leakage tests to the control of outer and inner contours to 100% high-voltage or voltage testing. In this way, we ensure that each part meets the highest requirements.

Our Specification

Our production is geared towards the highest precision and efficiency. With multi-cavity molds, we produce molds with up to 64 cavities and use both standard and stack molds. In addition, we have comprehensive material expertise:

- Specialty plastics: PEEK

- High-performance plastics: PSU, PES, PPS, PEI, PPA

- Engineering Plastics: PPE, PC, PBT, PET, POM, PA

- Standard plastics: PP, PS, ABS, PMMA, PE

- Fiber-reinforced thermoplastics

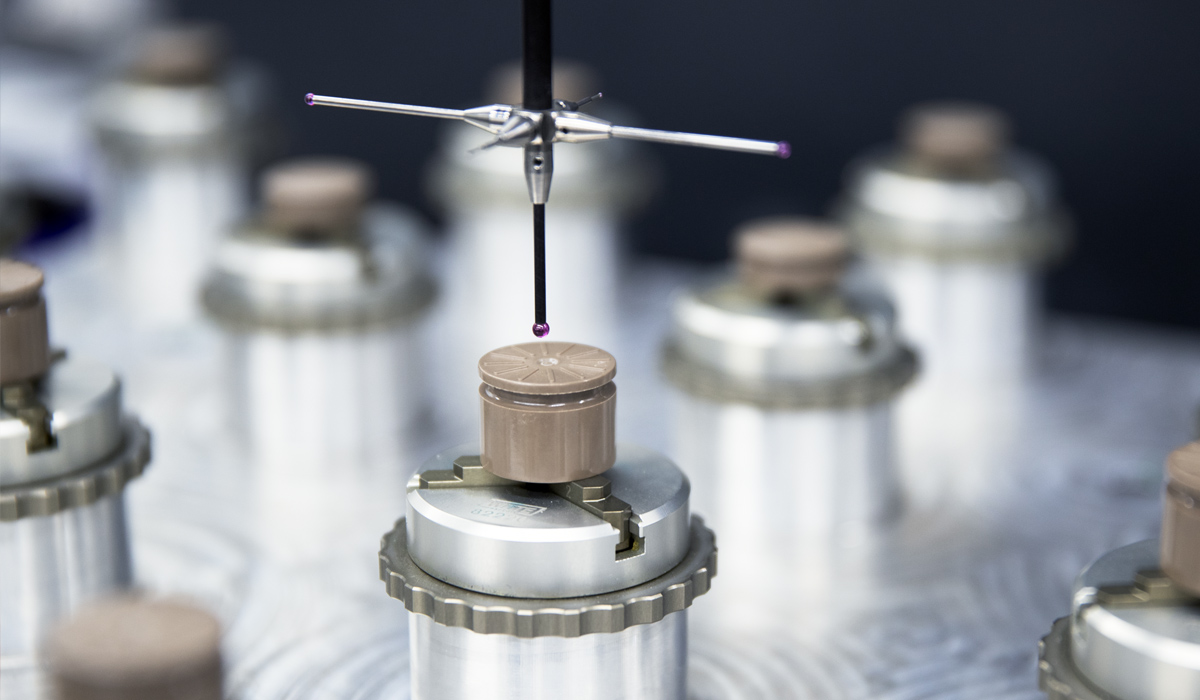

Our measurement technology

Highly qualified employees and a state-of-the-art measuring laboratory ensure the efficient assurance of component quality from the initial sampling to the product discharge. In our own laboratory , measuring equipment for 3D measurement, roughness analysis, contours and color measurement is available, among other things .