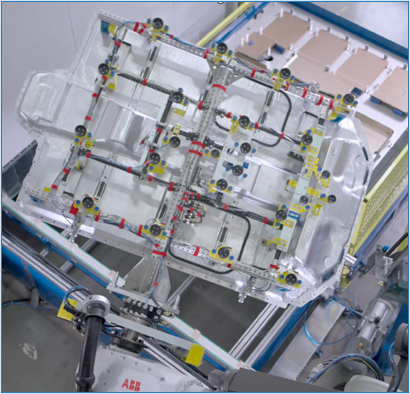

Röchling Automotive supplies Intrusion Protection for a major European OEM

- Protective panels from Röchling Automotive are used in several popular battery-powered models

- Manufactured in a sandwich construction from thermoplastic composites with continuous glass fiber reinforcement

- High protective performance with very low weight, fully recyclable material

Mannheim, December 2, 2025 | Röchling Automotive is expanding its collaboration with a major European OEM. Starting in 2027, the automotive supplier will produce an Intrusion Protection Plate for an entire platform. This means the component will be used in several electric vehicle models.

The Intrusion Protection Plate is a safety component with multiple functions. It acts as a physical barrier in electric vehicles, preventing objects from penetrating the battery during accidents.

Safe and Lightweight

For the protection plate, the plastics specialist relies on a sandwich structure made of thermoplastic composites with continuous glass fiber reinforcement (UD tapes). This product design combines strength with lightness and improves safety despite very low weight.

Martin Schüler, CEO of Röchling Automotive, describes the special product features as follows: “Despite their low weight, advanced thermoplastic composites offer excellent impact resistance and structural rigidity. This keeps the battery safe from flying debris, dirt, and stone impacts. Even in collisions, this protective effect remains.”

Another advantage is thermal insulation, which is an inherent property of thermoplastics. This helps maintain stable battery temperatures and reduces the risk of thermal runaway in the event of an accident. This contributes to both the safety and longevity of the battery.

Environmentally Friendly from Production Onward

“Thanks to the structure made of fiber-reinforced plastic, the environment also benefits,” Schüler continues. “The material enables efficient, waste-free production and is fully recyclable. This means we meet all sustainability goals of the automotive industry.”

Additionally, the production of thermoplastic composites generally requires less energy than the production of steel or aluminum. Combined with low weight, this helps reduce overall CO₂ emissions—both in production and during vehicle operation.

Due to these properties, thermoplastic intrusion protection is expected to become the preferred solution for securing drive batteries in the coming years. With this contract, Röchling Automotive ensures broad use of the technology in several popular vehicle models.