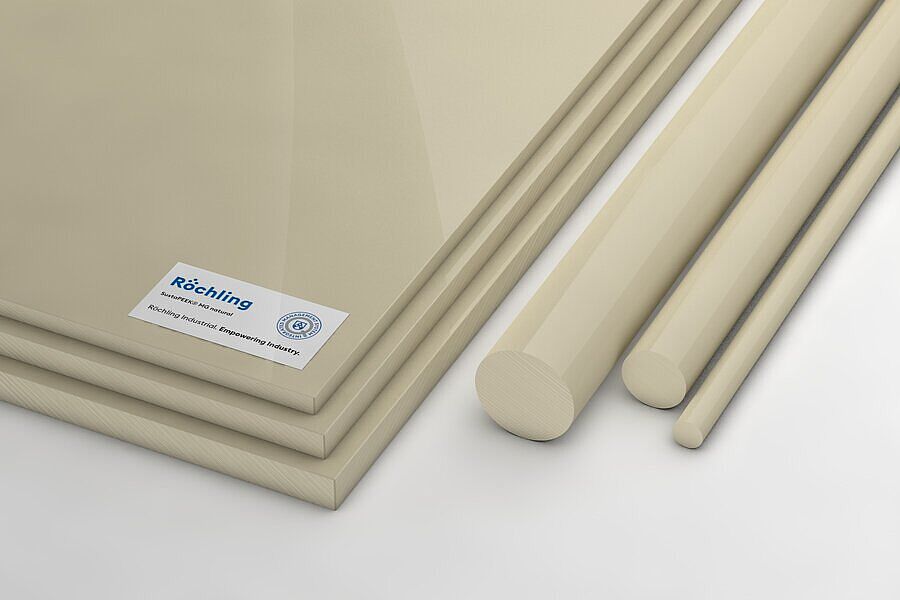

| No stock item (MOQ) | 600688 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 10 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

10 mm

| | |

| No stock item (MOQ) | 601306 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 100 x 1000 mm |

1.000 mm

| |

100 mm

| | |

| No stock item (MOQ) | 601944 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 20 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

20 mm

| | |

| No stock item (MOQ) | 605977 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 55 x 1000 mm |

1.000 mm

| |

55 mm

| | |

| No stock item (MOQ) | 615247 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 5 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

5 mm

| | |

| No stock item (MOQ) | 629918 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 200 x 1000 mm |

1.000 mm

| |

200 mm

| | |

| No stock item (MOQ) | 650387 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 36 x 2000 mm |

2.000 mm

| |

36 mm

| | |

| No stock item (MOQ) | 660888 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 60 x 1000 mm |

1.000 mm

| |

60 mm

| | |

| Stock item (no MOQ) | 673721 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 8 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

8 mm

| | |

| No stock item (MOQ) | 673723 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 8 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

8 mm

| | |

| No stock item (MOQ) | 673788 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 12 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

12 mm

| | |

| No stock item (MOQ) | 673789 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 12 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

12 mm

| | |

| No stock item (MOQ) | 760138 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 110 x 1000 mm |

1.000 mm

| |

110 mm

| | |

| No stock item (MOQ) | 760139 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 110 x 3000 mm |

3.000 mm

| |

110 mm

| | |

| No stock item (MOQ) | 765343 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 16 x 620 x 2000 mm |

2.000 mm

|

620 mm

|

16 mm

| | |

| Stock item (no MOQ) | 806297 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 32 x 3000 mm |

3.000 mm

| |

32 mm

| | |

| No stock item (MOQ) | 806416 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 20 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

20 mm

| | |

| No stock item (MOQ) | 806417 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 16 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

16 mm

| | |

| No stock item (MOQ) | 806419 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 16 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

16 mm

| | |

| No stock item (MOQ) | 806502 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 10 x 3000 mm |

3.000 mm

| |

10 mm

| | |

| No stock item (MOQ) | 806503 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 10 x 1000 mm |

1.000 mm

| |

10 mm

| | |

| No stock item (no MOQ) | 806506 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 40 x 3000 mm |

3.000 mm

| |

40 mm

| | |

| No stock item (MOQ) | 806507 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 40 x 1000 mm |

1.000 mm

| |

40 mm

| | |

| No stock item (no MOQ) | 806596 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 16 x 3000 mm |

3.000 mm

| |

16 mm

| | |

| No stock item (MOQ) | 806599 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 10 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

10 mm

| | |

| No stock item (no MOQ) | 806606 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 20 x 3000 mm |

3.000 mm

| |

20 mm

| | |

| No stock item (MOQ) | 806607 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 20 x 1000 mm |

1.000 mm

| |

20 mm

| | |

| No stock item (MOQ) | 806608 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 25 x 1000 mm |

1.000 mm

| |

25 mm

| | |

| No stock item (no MOQ) | 806609 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 25 x 3000 mm |

3.000 mm

| |

25 mm

| | |

| Stock item (no MOQ) | 806610 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 30 x 3000 mm |

3.000 mm

| |

30 mm

| | |

| No stock item (MOQ) | 806611 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 30 x 1000 mm |

1.000 mm

| |

30 mm

| | |

| No stock item (no MOQ) | 806635 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 6 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

6 mm

| | |

| Stock item (no MOQ) | 806637 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 30 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

30 mm

| | |

| No stock item (no MOQ) | 806642 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 50 x 3000 mm |

3.000 mm

| |

50 mm

| | |

| No stock item (no MOQ) | 806643 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 60 x 3000 mm |

3.000 mm

| |

60 mm

| | |

| No stock item (MOQ) | 806688 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 8 x 3000 mm |

3.000 mm

| |

8 mm

| | |

| No stock item (MOQ) | 806689 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 12 x 3000 mm |

3.000 mm

| |

12 mm

| | |

| No stock item (MOQ) | 806697 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 25 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

25 mm

| | |

| No stock item (MOQ) | 806698 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 30 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

30 mm

| | |

| No stock item (MOQ) | 806699 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 6 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

6 mm

| | |

| No stock item (MOQ) | 806924 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 6 x 3000 mm |

3.000 mm

| |

6 mm

| | |

| No stock item (MOQ) | 806925 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 45 x 3000 mm |

3.000 mm

| |

45 mm

| | |

| No stock item (MOQ) | 806926 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 70 x 3000 mm |

3.000 mm

| |

70 mm

| | |

| No stock item (no MOQ) | 806927 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 80 x 3000 mm |

3.000 mm

| |

80 mm

| | |

| No stock item (MOQ) | 807276 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 50 x 1000 mm |

1.000 mm

| |

50 mm

| | |

| No stock item (MOQ) | 807608 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 45 x 1000 mm |

1.000 mm

| |

45 mm

| | |

| No stock item (MOQ) | 808145 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 12 x 1000 mm |

1.000 mm

| |

12 mm

| | |

| No stock item (MOQ) | 808190 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 36 x 3000 mm |

3.000 mm

| |

36 mm

| | |

| No stock item (MOQ) | 808513 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 70 x 1000 mm |

1.000 mm

| |

70 mm

| | |

| No stock item (MOQ) | 808686 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 6 x 1000 mm |

1.000 mm

| |

6 mm

| | |

| No stock item (MOQ) | 809019 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 16 x 1000 mm |

1.000 mm

| |

16 mm

| | |

| No stock item (MOQ) | 809020 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 32 x 1000 mm |

1.000 mm

| |

32 mm

| | |

| No stock item (MOQ) | 809170 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 5 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

5 mm

| | |

| No stock item (MOQ) | 810172 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 120 x 1000 mm |

1.000 mm

| |

120 mm

| | |

| No stock item (MOQ) | 810173 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 120 x 3000 mm |

3.000 mm

| |

120 mm

| | |

| No stock item (MOQ) | 921774 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 80 x 1000 mm |

1.000 mm

| |

80 mm

| | |

| No stock item (MOQ) | 924805 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 8 x 1000 mm |

1.000 mm

| |

8 mm

| | |

| Stock item (no MOQ) | 926450 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 100 x 3000 mm |

3.000 mm

| |

100 mm

| | |

| No stock item (MOQ) | 931215 | SustaPEEK MG natural extruded |

rod

|

rod

| natural | Ø 36 x 1000 mm |

1.000 mm

| |

36 mm

| | |

| No stock item (no MOQ) | 931249 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 40 x 620 x 3000 mm |

3.000 mm

|

620 mm

|

40 mm

| | |

| No stock item (MOQ) | 931373 | SustaPEEK MG natural extruded |

sheet

|

sheet

| natural | 40 x 620 x 1000 mm |

1.000 mm

|

620 mm

|

40 mm

| | |