Select a different country or region to see specific content for your location.

LubX® AST black - antistatic sliding material

The antistatic sliding material LubX® AST black combines excellent tribological properties with controlled electrostatic dissipation and is specifically designed for machines in conveying systems that have to be operated at high speeds.

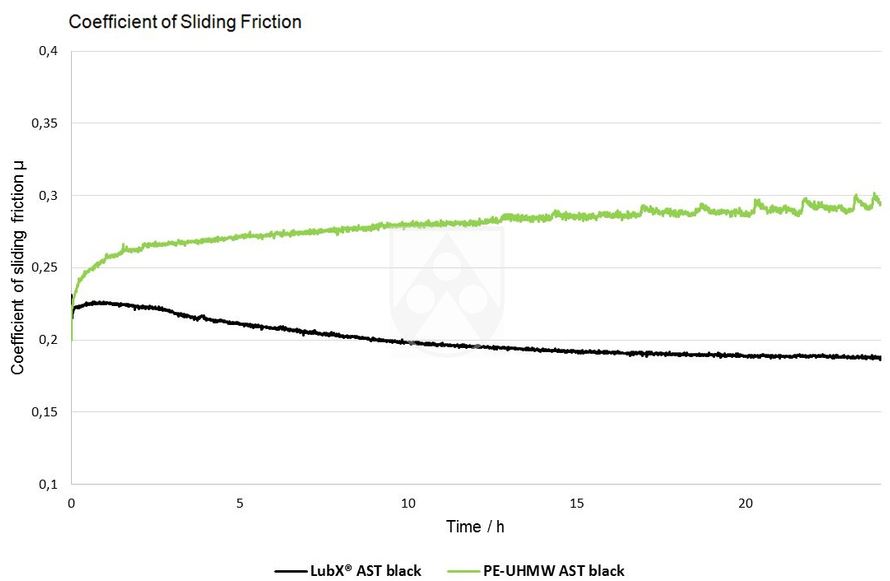

- In comparison to standard antistatic materials for machine construction, LubX® AST black, with a sliding friction coefficient of µ: 0.19, offers more than 30% better sliding properties.

- In combination with permanent antistatic properties, LubX® AST black improves the economic efficiency of your transport processes and allows controlled dissipation.

Your Advantages

- Protection against static charges

- Reduced soiling resulting from static charges, no attraction of dirt particles

- Short running-in period

- Reduced heat generation

- Long service life

Special properties

- Surface resistance < 109 Ω

- Improved sliding properties

- Good dry running properties

- Resistance to wear

Type of Product

- Sheets

- Extruded profiles

- Round rods

- Prefabricated components according to customer's drawing

Colour

- black