Plastics for the beverage industry

Tough and efficient machines are essential in the beverage industry especially. Across the world numberless of bottles leave the "assembly line" every year. Bottling plants must be reliable even in the face of high filling amounts in a short space of time. The machine components must not cause any damage to bottles or labels, however. We offer plastics with excellent slide properties and high wear resistance specifically for these requirements. By helping to protect your conveying and bottling plants, they improve both cost-effectiveness and service life.

Your advantages

- Good slide friction helps improve the cost-effectiveness of your production processes

- Reduced energy demand

- Slip-stick effects are avoided

- Bottles are conveyed gently

- Noise reduction

- High process stability

Typical areas of application

- Beverage bottling equipment

- Conveyor systems

Application examples

Related Products

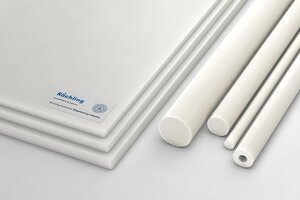

- PE > PE-UHMW - PE 1000

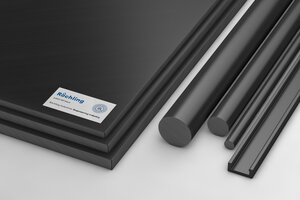

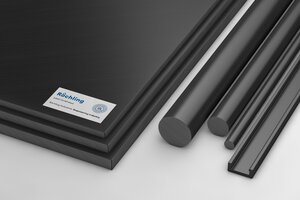

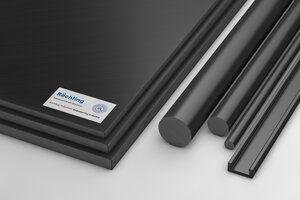

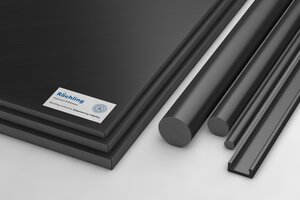

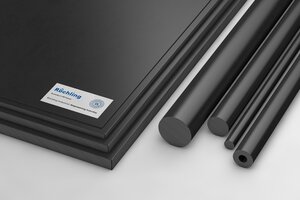

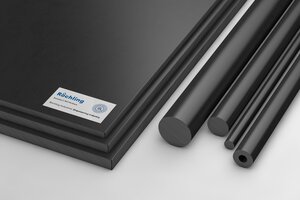

LubX® AST black

- PE > PE-UHMW - PE 1000

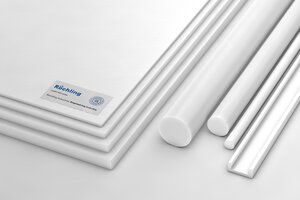

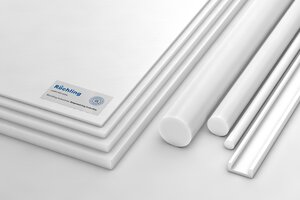

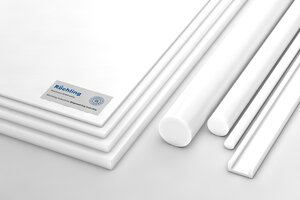

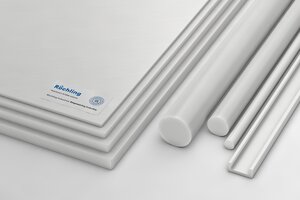

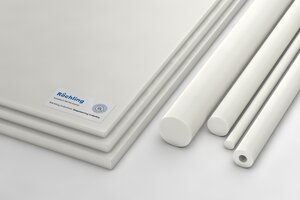

LubX® AST white

- PE > PE-UHMW - PE 1000

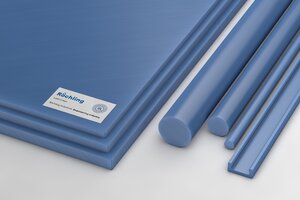

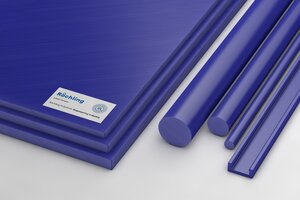

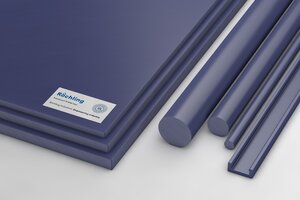

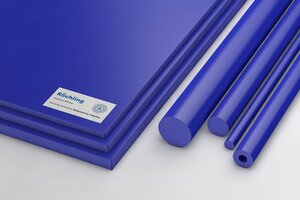

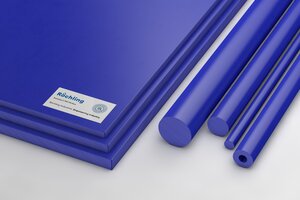

LubX® C blue

- PE > PE-UHMW - PE 1000

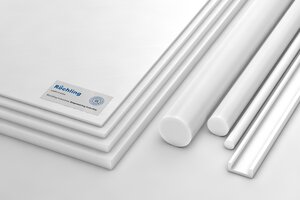

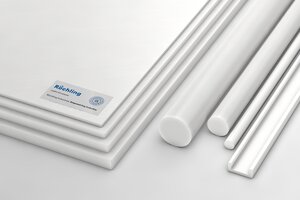

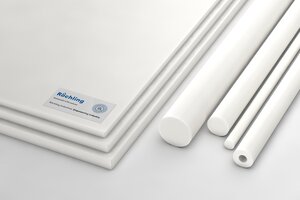

LubX® C natural

- PE > PE-UHMW - PE 1000

LubX® C white

- PE > PE-UHMW - PE 1000

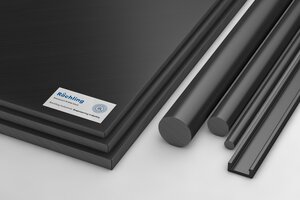

LubX® CV AST black

- PE > PE-UHMW - PE 1000

LubX® CV AST white

- PE > PE-UHMW - PE 1000

LubX® CV blue

- PE > PE-UHMW - PE 1000

LubX® CV natural

- PE > PE-UHMW - PE 1000

Polystone® M AST + FDA black

- PE > PE-UHMW - PE 1000

Polystone® M EHS + AST black

- PE > PE-UHMW - PE 1000

Polystone® M EHS black

- PE > PE-UHMW - PE 1000

Polystone® M EHS natural

- PE > PE-UHMW - PE 1000

Polystone® M EHS red

- PE > PE-UHMW - PE 1000

Polystone® M EHS white

- PE > PE-UHMW - PE 1000

Polystone® M EL + EHS black

- PE > PE-UHMW - PE 1000

Polystone® M Slide black

- PE > PE-UHMW - PE 1000

Polystone® M Slide blue

- PE > PE-UHMW - PE 1000

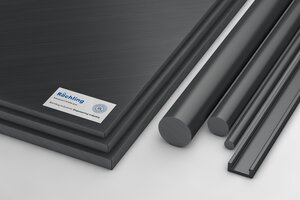

Polystone® M Slide grey

- PE > PE-UHMW - PE 1000

Polystone® M Slide natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft natural

- PE > PE-UHMW - PE 1000

Polystone® M Soft white

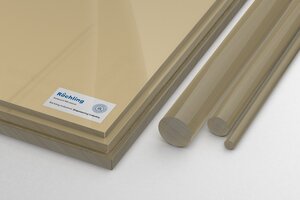

- PA > PA 6 G

Sustaglide® green

- PA > PA 6

Sustamid® 6 FG natural

- PEEK

SustaPEEK FG natural

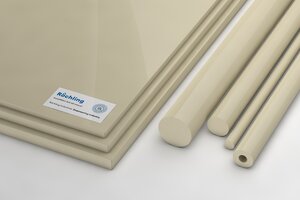

- PVDF

SustaPVDF FG natural

Arrange technical advice

The performance and service life of materials used for the construction of plants in the beverage industry are influenced by many different factors. These criteria need to be considered in order to make the right choice. Examples:

- Use at high and low temperatures

- Mechanical loading

- Contact with detergents and disinfectants

- Design requirements

- Dimensions and tolerances

We are happy to advise you on the selection of suitable materials for your particular application. Just use our contact form at the bottom of the page and write to us.