Your Development & Engineering Partner

Our in-house development team of designers, engineers and ergonomists combines innovative strength with many years of industry experience and in-depth engineering knowledge. Our customers use our expertise in plastics and metal processing for the medical and pharmaceutical industry to consult us as a development partner – whether for a new product development or the improvement of an existing design.

From Idea to Series Production

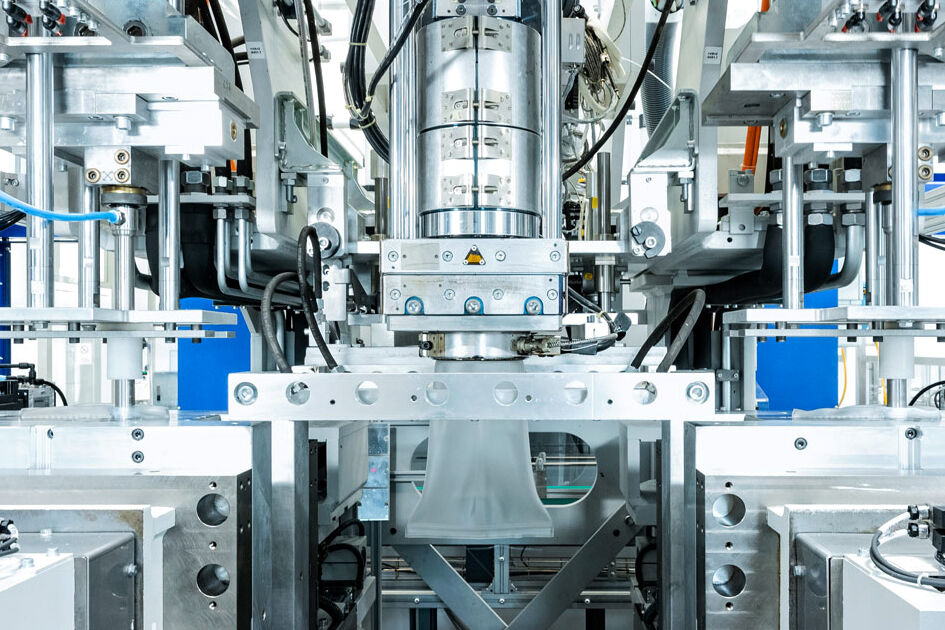

We prefer to be involved right from the start to accompany you holistically in your development process: from feasibility analysis, material selection and determining manufacturing requirements to component design, initial prototyping and into ongoing series production.

The earlier we are involved, the more effectively our product engineering experts can ensure that your design is optimized from the outset in terms of its function, quality, price-performance ratio and time-to-market.

Our customers appreciate our creative approach to finding solutions - for example in joint innovation workshops for idea generation - and our ability to realize ideas through a lean and transparent project organization.

Design for Manufacturing in Plastics and Metal

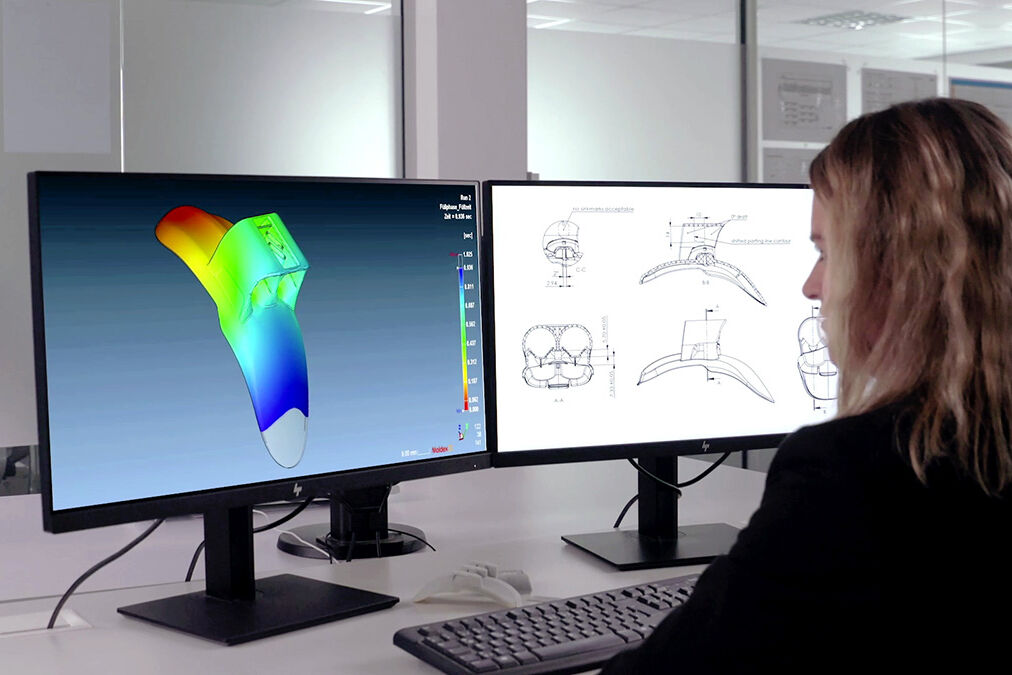

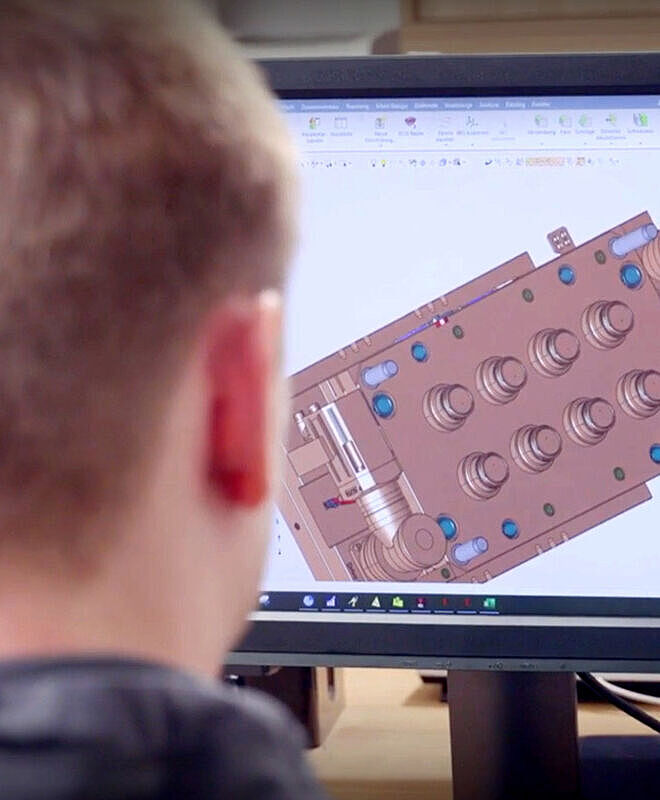

In the design and tolerancing of plastic parts, special know-how is required to optimize the manufacturing process, ensure process reliability and reduce costs.

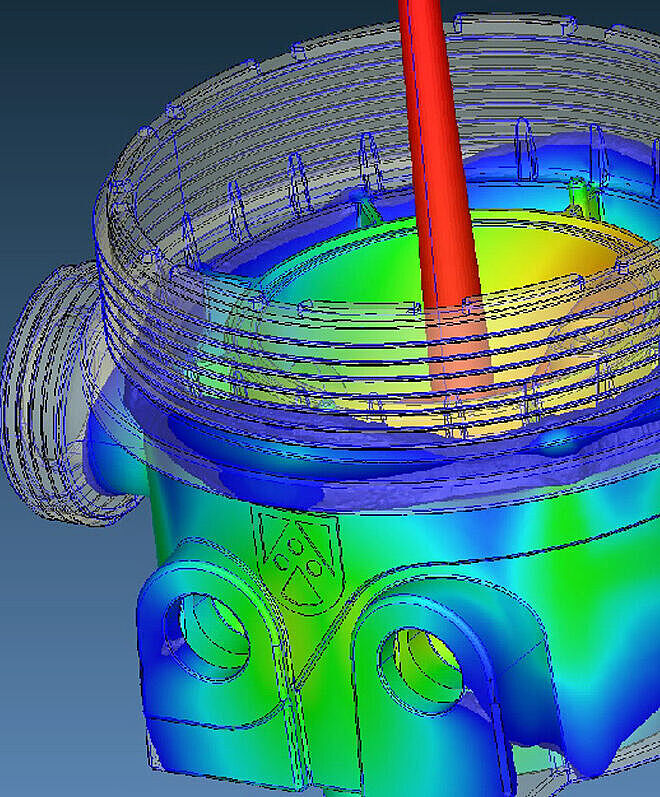

We work with state-of-the-art design and development tools and carry out extensive simulations prior to constructing the molding tools in order to optimize aspects such as wall thickness, undercuts and radii. Our many years of know-how in the processing of plastics for medical device, pharma packaging and drug delivery solutions is incorporated into every step of the process.

With our stainless steel and titanium processing expertise in the United States, we are a competent partner when it comes to the combination of plastics and metal in medical devices.

We Support Your Successful Launch

To ensure a successful launch of the new development, we take care of all necessary documentation required for the approval of the products according to the applicable standard (ISO 13485, ISO 15378). This includes, for example, requirement specifications, design FMEA, test protocols or production data sheets.

Shaping the Future – Innovation at Röchling Medical

Taking into account usability and human factors in medical device design and the development of pharmaceutical packing and drug delivery solutions is key for a safe, effective end product.

We leverage our partnerships with medical experts, hospitals, universities and research institutes to gain insights for user- and patient-centric design and actively engage with technologies and topics that will shape the future – such as the healthcare digitizing, additive manufacturing technologies and design for sustainability.

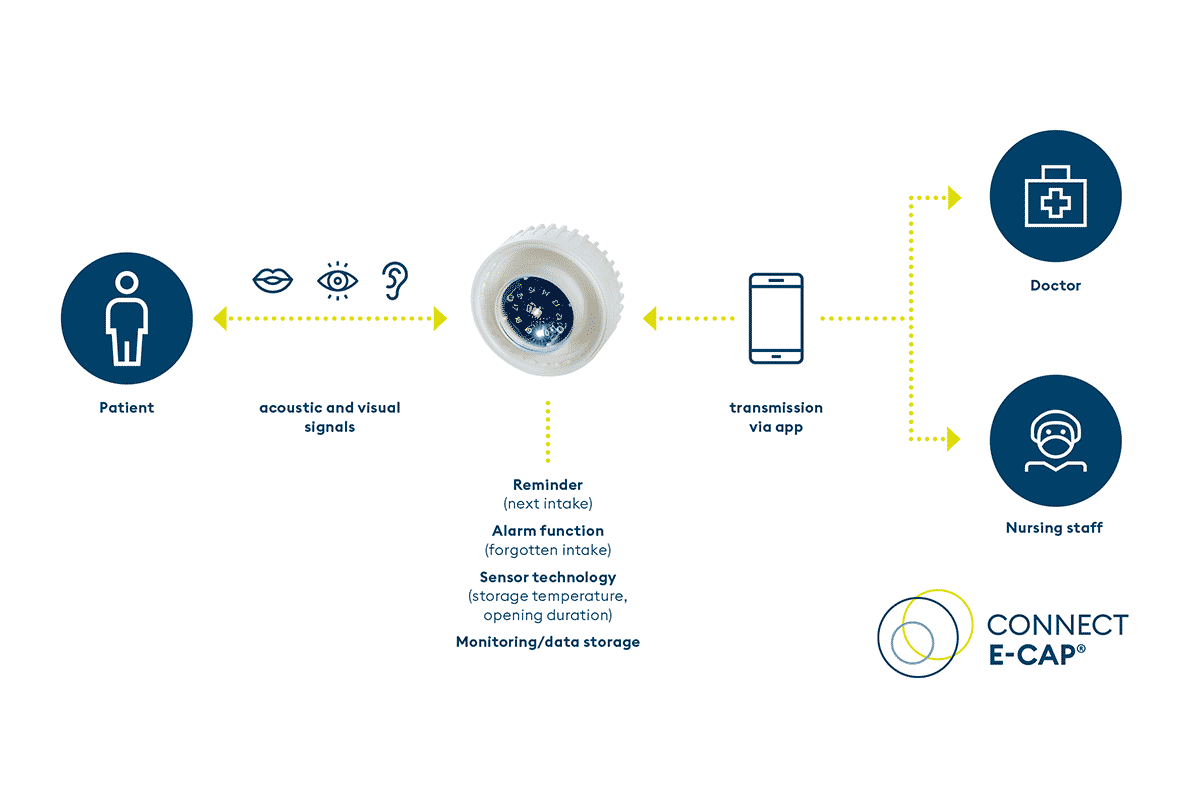

Digital technologies and their integration into medical devices and applications for the pharmaceutical industry are also the drivers and motivation behind our own research and developments, such as Connect-e-Cap® or the use of marker technology for the clear component authentication and identification.

How We Innovate

Product Innovation

- Network of experts (universities, research institutes, healthcare professionals)

- Customer innovation workshops and design thinking

- Smart approaches to individualizing

- Connected products: integration of electronics and sensor

Material Innovation

- Smart material combinations: hybrid and multilayer solutions, multi-component plastic products (2K), combinations of plastics and metal

- Sustainable material solutions

- Functionalized polymers and coatings

- Use of marker technology

Process Innovation

- Rethinking and recombining technologies

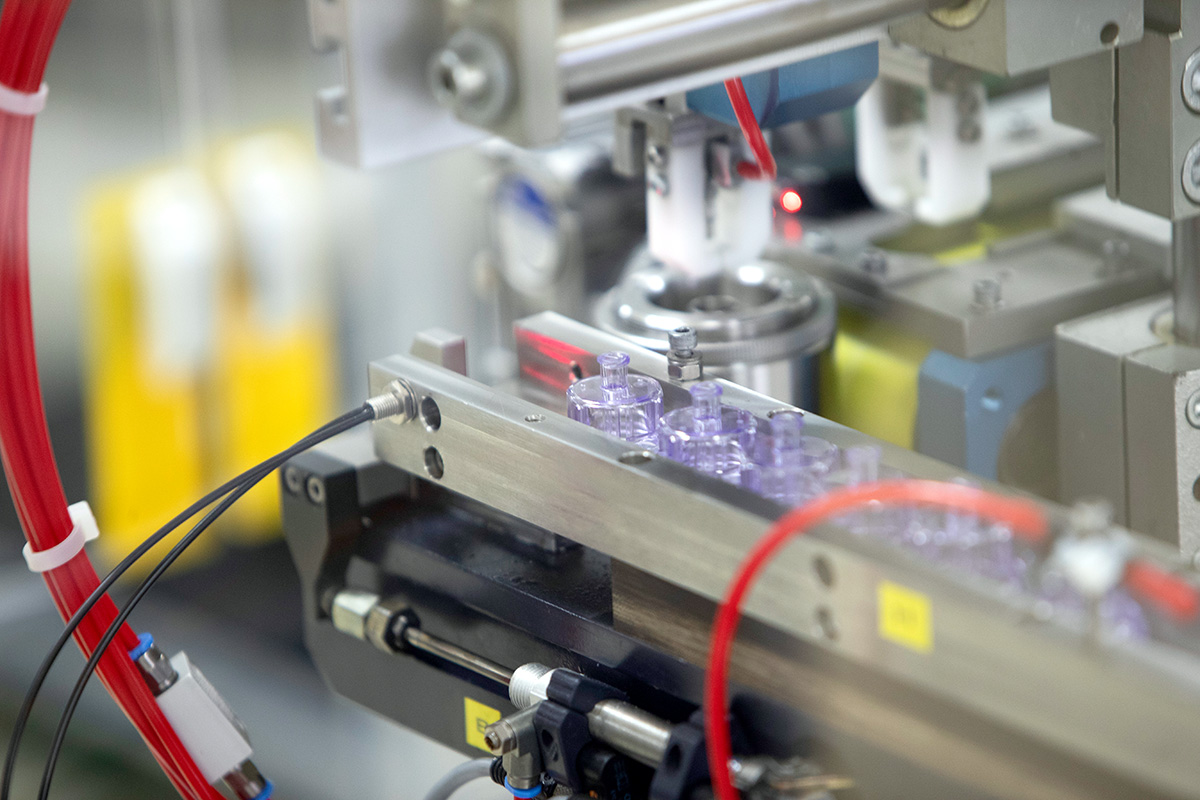

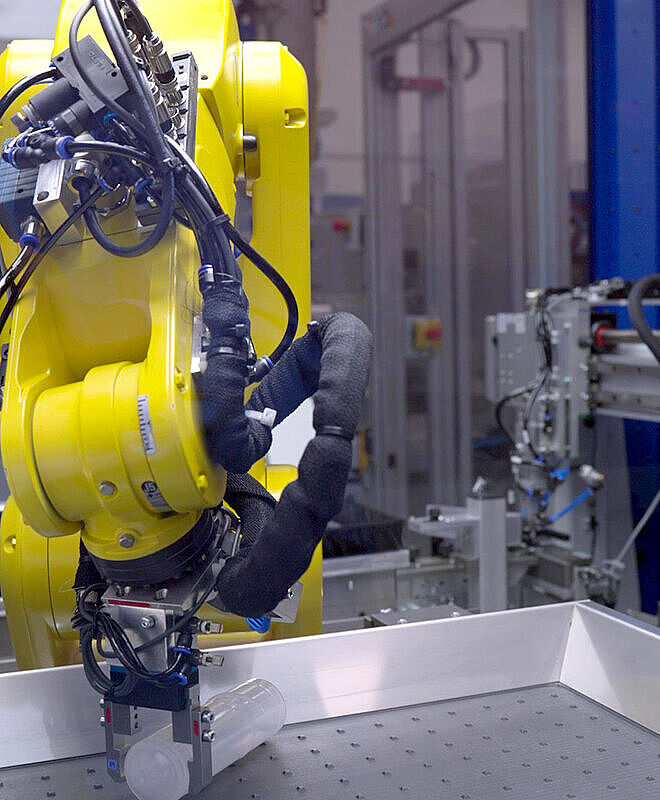

- Smart automation solutions along the whole process chain

- Advanced simulations

- Digital Twinning

- Use of 3D printing in mold design

- Recycling concepts

Competences at the Following Locations

Case Studies

As a solution provider, we combine our expertise in research & product development, materials & technologies, and automation & industrialization with our experience, our quality standards, and our ambition to work with our customers to design a product that meets their individual requirements.

Our case studies give you an insight into the challenges faced by our customers in pharma, diagnostics and medical technology sectors and the tailor-made solutions that we jointly created for them.

Patient-Centric Pharmaceutical Packaging Design

Optimizing a Complex Class 3 Medical Device

Innovative Plastic Protectors for Glass Injection Vials

Custom Automation Concepts

Design for Manufacturability

Automated Quality Control

Metal and Plastic Processing from a Single Source

Medical Device Contract Manufacturing

A Single Use Medical Device Designed for Sustainability

Simulations in Product Development

Röchling Medical Competences

Our Expertise, Your Benefit

Our customers benefit from our extensive expertise in plastics and metal processing, but also from our many years of experience in medical technology and pharma. As your solution partner, we are familiar with both the regulatory and practical requirements of creating components and products for the healthcare sector tailored to your needs. We meet the highest quality and hygiene standards and operate in strict compliance with relevant regulations, such as the Medical Device Regulation (MDR).

Contact Us

For more information about our solutions for diagnostics and customized design options, please contact our team.

We look forward to hearing from you.

Your Contact in Europe

Thierry Arnaud

Vice President - Sales & Marketing Europe

Markus Fritzmann

Head of Regional Sales

Klaus Kantorczyk

Head of Key Account Management

Your Contact in the US

Bill Ruth

Vice President - Sales & Marketing